Plastic pipe preparation process

A preparation process and technology of plastic pipes, which are applied in the field of plastic pipes, can solve the problems of high temperature resistance and low corrosion resistance, lower water quality, cleanliness, and short service life, and achieve stable corrosion resistance, inhibit the growth of bacteria, and excellent mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

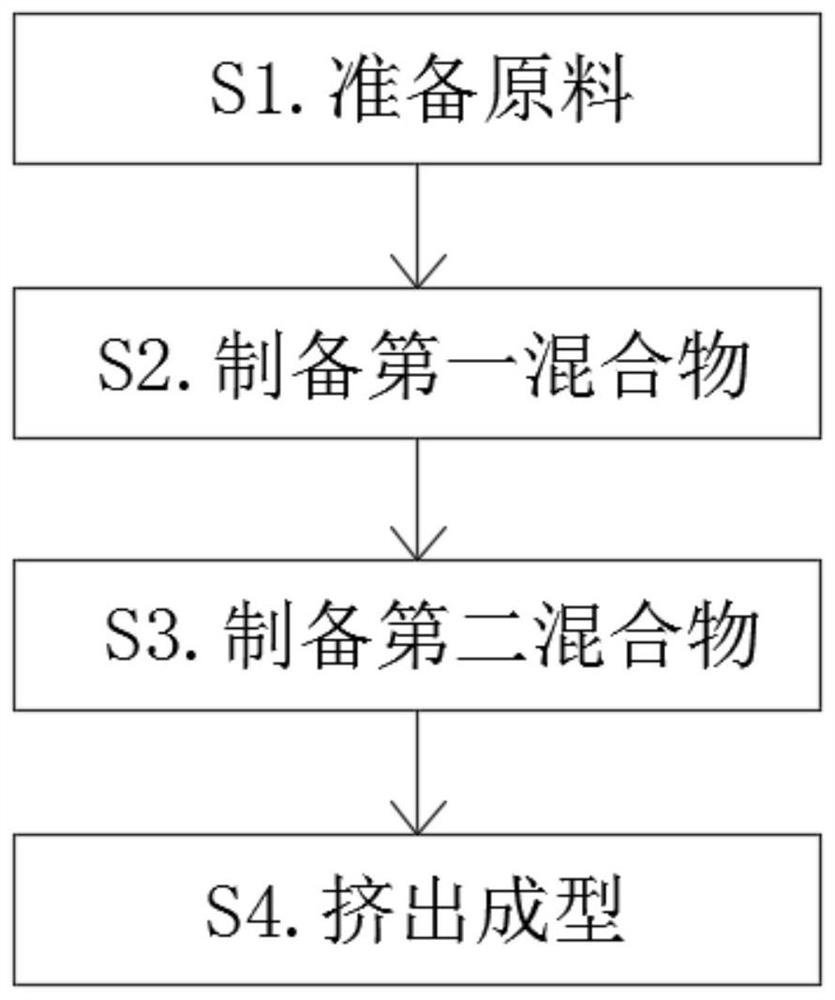

[0023] see figure 1 , the present invention provides a technical solution: a plastic pipe preparation process, comprising the following steps:

[0024] S1. Prepare raw materials: select according to the following parts by weight: 40 parts of polypropylene resin, 50 parts of polyvinyl chloride resin, 30 parts of nano-scale antibacterial masterbatch, 1 part of polytetrafluoroethylene resin, 1 part of triphenyl phosphite, lemon 2.5 parts of triethyl ester, 1 part of calcium carbonate, 1 part of silicon powder, 2.2 parts of butyl stearate, 2 parts of bentonite, 1 part of epoxy soybean oil, 1.2 parts of antioxidant synergist;

[0025] S2. Prepare the first mixture: select polypropylene resin, polyvinyl chloride resin, nano-scale antibacterial masterbatch, polytetrafluoroethylene resin, butyl stearate, bentonite, and epoxy soybean oil in S1 to add and mix by parts by weight In a blender, stir and mix thoroughly to obtain the first mixture;

[0026] S3. Prepare the second mixture: ...

Embodiment 2

[0037] see figure 1 , the present invention provides a technical solution: a plastic pipe preparation process, comprising the following steps:

[0038] S1. Prepare raw materials: select according to the following parts by weight: 70 parts of polypropylene resin, 70 parts of polyvinyl chloride resin, 60 parts of nano-scale antibacterial masterbatch, 4 parts of polytetrafluoroethylene resin, 2 parts of triphenyl phosphite, lemon 3.5 parts of triethyl ester, 5 parts of calcium carbonate, 5 parts of silicon powder, 2.8 parts of butyl stearate, 8 parts of bentonite, 3 parts of epoxy soybean oil, 1.6 parts of antioxidant synergist;

[0039] S2. Prepare the first mixture: select polypropylene resin, polyvinyl chloride resin, nano-scale antibacterial masterbatch, polytetrafluoroethylene resin, butyl stearate, bentonite, and epoxy soybean oil in S1 to add and mix by parts by weight In a blender, stir and mix thoroughly to obtain the first mixture;

[0040]S3. Prepare the second mixtu...

Embodiment 3

[0051] see figure 1 , the present invention provides a technical solution: a plastic pipe preparation process, comprising the following steps:

[0052] S1. Prepare raw materials: select according to the following parts by weight: 50 parts of polypropylene resin, 60 parts of polyvinyl chloride resin, 40 parts of nano-scale antibacterial masterbatch, 3 parts of polytetrafluoroethylene resin, 1.5 parts of triphenyl phosphite, lemon 2.8 parts of triethyl ester, 3 parts of calcium carbonate, 3 parts of silicon powder, 2.5 parts of butyl stearate, 4 parts of bentonite, 2 parts of epoxy soybean oil, 1.4 parts of antioxidant synergist;

[0053] S2. Prepare the first mixture: select polypropylene resin, polyvinyl chloride resin, nano-scale antibacterial masterbatch, polytetrafluoroethylene resin, butyl stearate, bentonite, and epoxy soybean oil in S1 to add and mix by parts by weight In a blender, stir and mix thoroughly to obtain the first mixture;

[0054] S3. Prepare the second mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com