Waste-free resource circulating utilization process and system based on biomass pyrolysis carbonization

A biomass charcoal and pyrolysis charcoal technology, which is applied in the fields of biofuel, steam generation method using heat carrier, petroleum industry, etc., can solve the problems of easy re-ignition of carbon-based production, waste of biomass energy and affecting the quality of carbon, etc. To achieve the effect of reducing the influence of heat exchange tube material and welding, high economic and social benefits, and improving the efficiency of waste heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

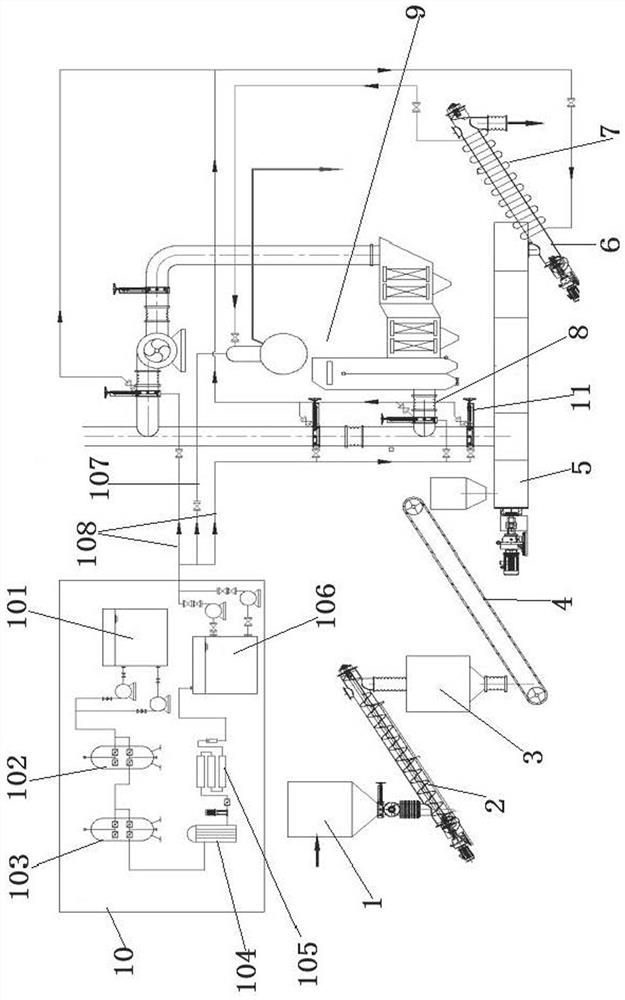

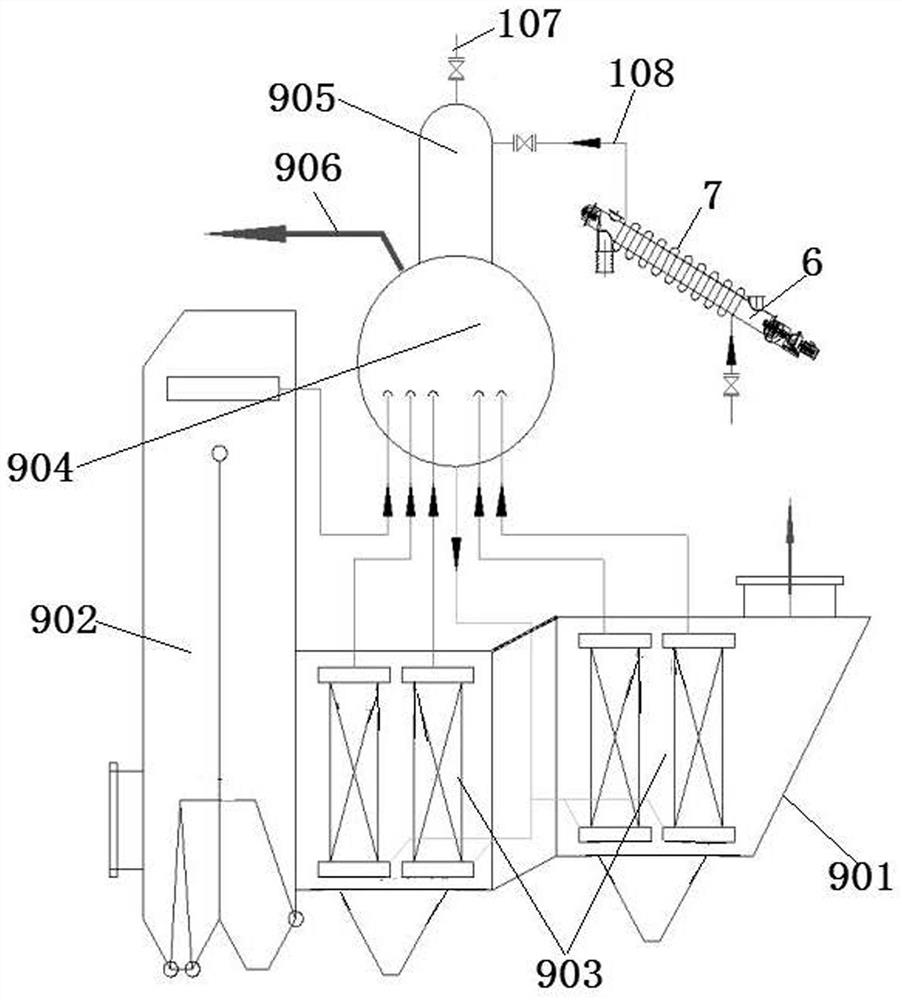

[0026] Example. Based on the waste-free recycling process of biomass pyrolysis and carbonization, the agricultural and forestry solid waste biomass materials are converted into biomass carbon-based raw materials after crushing and anoxic carbonization treatment, and the biomass carbon-based raw materials are cooled to form carbon required for finishing base; the harmless high-temperature flue gas produced during the carbonization process is recovered and treated by the waste heat boiler, and the flue gas temperature is lowered before the flue gas discharge operation; at the same time, the waste heat boiler generates saturated steam during the recovery process for users to recycle.

[0027] The agricultural and forestry solid waste biomass is conveyed by the conveyor to the crusher for crushing to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com