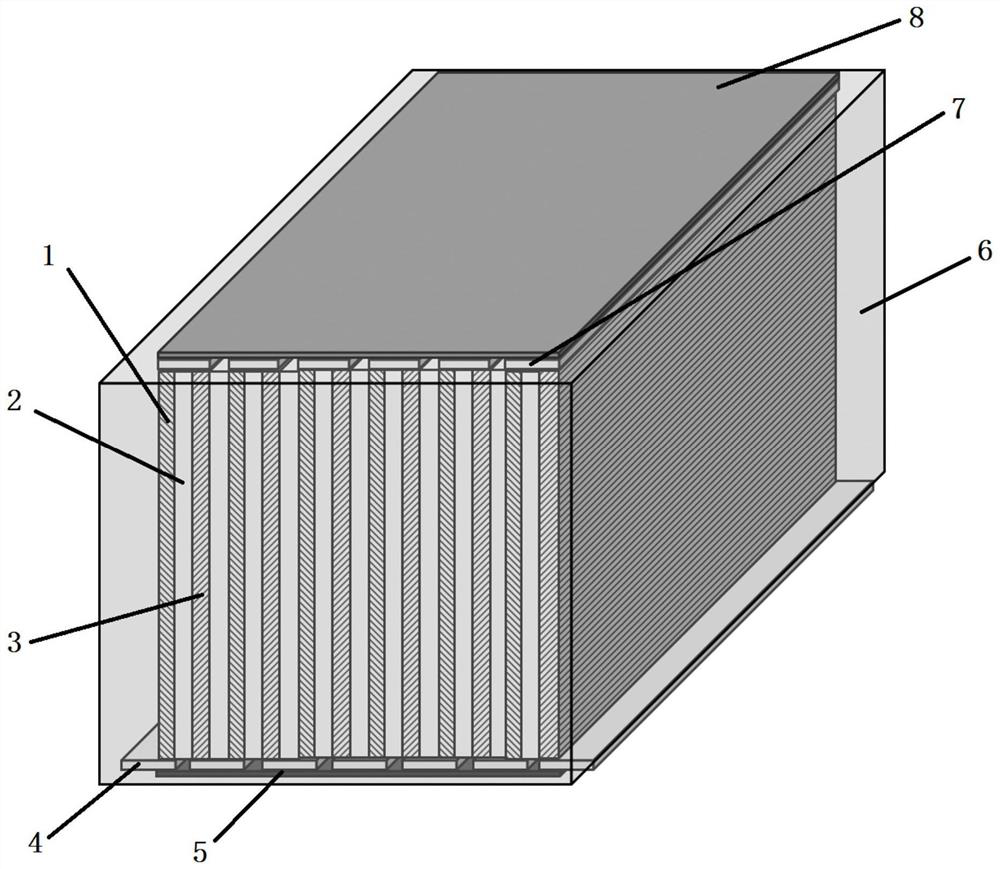

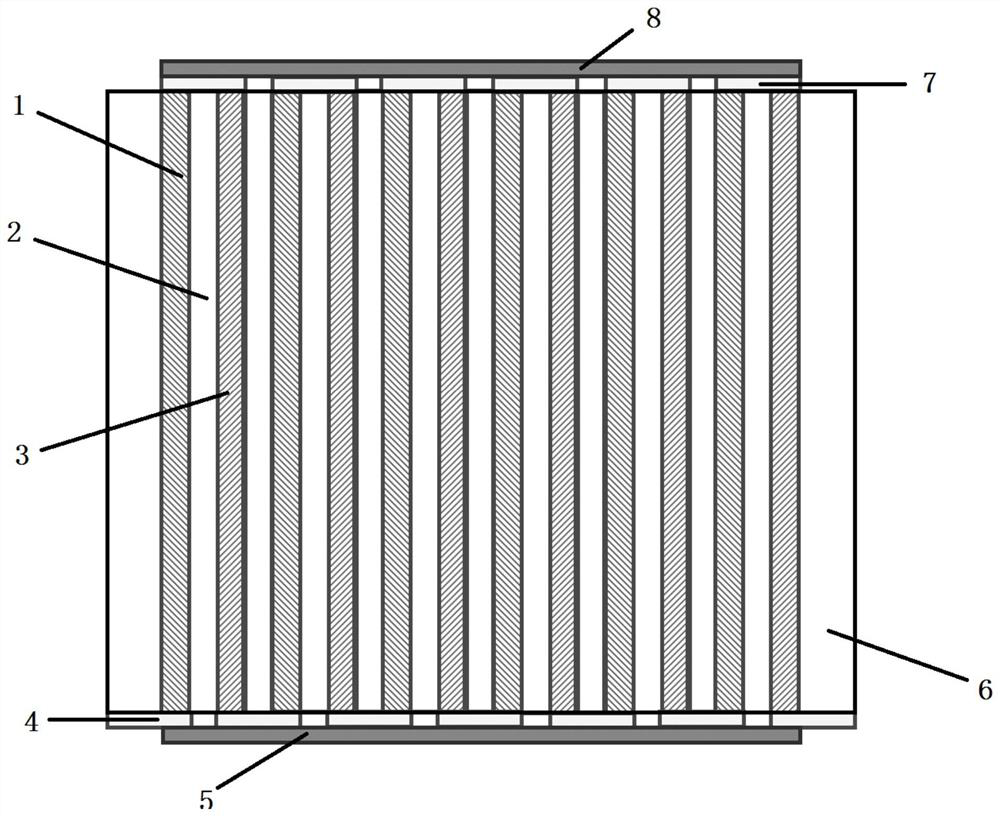

Temperature difference power generation device with laminated structure and preparation method thereof

A technology of thermoelectric power generation and layered structure, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric devices using only Peltier or Seebeck effect, etc. Resistance and other problems, to achieve low structural resistance and thermal resistance, improve thermoelectric conversion efficiency, and increase the effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] An embodiment of the present invention provides a method for preparing a thermoelectric power generation device with a laminated structure, including the following steps:

[0051] (1) Sb 2 Te 3 The ingot of the base semiconductor thermoelectric material is wire-cut into P-type thermoelectric sheets with a thickness of 400-1000 μm, and the crystal ingot of the BiTeSe-based semiconductor thermoelectric material is wire-cut into N-type thermoelectric sheets with a thickness of 400-1000 μm. The double-sided polishing of the P-type thermoelectric sheet and the N-type thermoelectric sheet has a surface roughness lower than 10 μm;

[0052] (2) Spin-coat polystyrene layers of insulating glue on both sides of the P-type thermoelectric sheet and the N-type thermoelectric sheet described in step (1), the thickness of the polystyrene layer is 5-50 μm;

[0053] (3) P-type thermoelectric sheets coated with polystyrene layers and N-type thermoelectric sheets are alternately attached...

Embodiment 2

[0059] This embodiment provides a method for preparing a thermoelectric power generation device with a laminated structure, including the following steps:

[0060] (1) P-type thermoelectric sheets and N-type thermoelectric sheets with a thickness of 10-200 μm were prepared respectively by screen printing;

[0061] Wherein, the preparation of the N-type thermoelectric sheet:

[0062] 1000 mesh Bi 2 Te 2.7 Se 0.3 After adding 95% alcohol, the powder is mixed with agate balls, sealed in an agate grinding tank, exhausted with nitrogen, and placed in a planetary ball mill at a speed of 300-500 rpm for 24 hours to obtain a superfine powder slurry. Take a quartz substrate with a thickness of 500 μm and place it on the lower end of the screen of the screen printing machine, smear the slurry on the screen and scrape the screen with a scraper to complete the printing. After the printed film is dried with a heat gun at 80°C, the above operations can be repeated to obtain an N-type th...

Embodiment 3

[0072] This embodiment provides a method for preparing a thermoelectric power generation device with a laminated structure, including the following steps:

[0073] (1) P-type thermoelectric flakes and N-type thermoelectric flakes with a thickness of 0.1-10 μm are prepared respectively by magnetron sputtering;

[0074] Wherein, the preparation of the N-type thermoelectric sheet:

[0075] The quartz substrate with a thickness of 50 μm was ultrasonically cleaned with deionized water, ethanol, and acetone, dried, and loaded into the magnetron sputtering sample stage. Bi 2 Te 2.7 Se 0.3 The target material is loaded into the target table of the magnetron sputtering equipment, and the vacuum is evacuated to reach the back pressure of 5×10 -4 Pa, inflate argon gas at a flow rate of 50-100 sccm, and maintain the pressure in the chamber at 0.5-3 Pa by adjusting the pumping valve. Heat the substrate to 200-400°C, start the DC sputtering power supply so that the sputtering power is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com