Production equipment and preparation method of high-content polyoxin raw powder

A polyoxin, high-content technology, applied in botany equipment and methods, biocides, biocides, etc., can solve the problems of poor quality of compound pesticide preparations, poor stability of physical and chemical conditions, complex material properties, etc., to achieve anti-bacteria Improve pollution performance, improve spray drying efficiency, and reduce the effect of macromolecular organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]1) There is no need to inactivate after the fermentation, the circulating water is cooled to 25℃±2℃, the materials are sent to the acidification tank, acidified with oxalic acid to pH 3.0, stand for 2h~3h, and the intermediate control temperature is 20℃~25℃.

[0051]2) The material is filtered through a plate and frame, and the clear liquid is collected. The filter cake is top washed with 10%~15% of the fermentation broth volume without salt water. The filtration time is controlled within 6h~12h, and the clear liquid content is 2500mg / L~3000 mg / L. 0.3g / L sodium bisulfite was added to the filtrate.

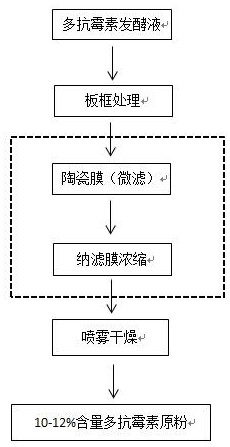

[0052]3) Ultrafiltration membrane treatment: the filtrate enters the ultrafiltration membrane for filtration. The ultrafiltration membrane selects a ceramic membrane with a molecular weight cut-off of 10000Da. The inlet pressure is 0.035MPa~0.040MPa, and the pressure behind the membrane is 0.015MPa~0.02MPa. Collect the clear liquid and the late concentrated liquid. Replenish an appropria...

Embodiment 2

[0061]1) After the fermentation, there is no need to inactivate, the circulating water is cooled to 25℃, the materials are sent to the acidification tank, and the pH is acidified with oxalic acid to 4.0, and then left for 2h~3h. The intermediate control temperature is 20℃~25℃.

[0062]2) The material is filtered through a plate and frame, and the clear liquid is collected. The filter cake is top washed with 10%~15% of the fermentation broth volume without salt water. The filtration time is controlled within 6h~12h, and the clear liquid content is 2500mg / L~3000 mg / L. Add 0.3-0.5g / L of sodium bisulfite and sodium metabisulfite mixture (configured in a 2:1 mass ratio) to the filtrate.

[0063]3) Ultrafiltration membrane treatment: the filtrate enters the ultrafiltration membrane for filtration. The ultrafiltration membrane selects a ceramic membrane with a molecular weight cut-off of 10000Da. The inlet pressure is 0.035MPa~0.040MPa, and the pressure behind the membrane is 0.015MPa~0.02MPa. C...

Embodiment 3

[0072]1) After the fermentation, there is no need to inactivate, the circulating water is cooled to 25℃, the materials are transferred to the acidification tank, and the pH is acidified with oxalic acid to 3.5. After the acidification, the potency is 3000mg / L~4000mg / L, standing for 2h~3h, intermediate control The temperature is 20℃~25℃.

[0073]2) The material is filtered through a plate and frame, and the clear liquid is collected. The filter cake is top washed with 10-15% of the fermentation broth volume without salt water. The filtering time is controlled at 6-12h, and the clear liquid content is 2500-3000 mg / L, and the filtrate is added 0.3~0.5g / L sodium metabisulfite.

[0074]3) Ultrafiltration membrane treatment: the filtrate enters the ultrafiltration membrane for filtration. The ultrafiltration membrane selects a ceramic membrane with a molecular weight cut-off of 10,000 Daltons. The inlet pressure is 0.035~0.040MPa, and the pressure behind the membrane is 0.015~0.02MPa. The clear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com