Fabricated building thermal insulation wallboard and preparation method thereof

A building insulation and prefabricated technology, applied in the field of building materials, can solve the problems of adverse effects of the living environment, short life of insulation wall panels, poor waterproof and moisture-proof performance, etc., and achieve the advantages of not easy to break, strong external pressure, and reduce the use of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

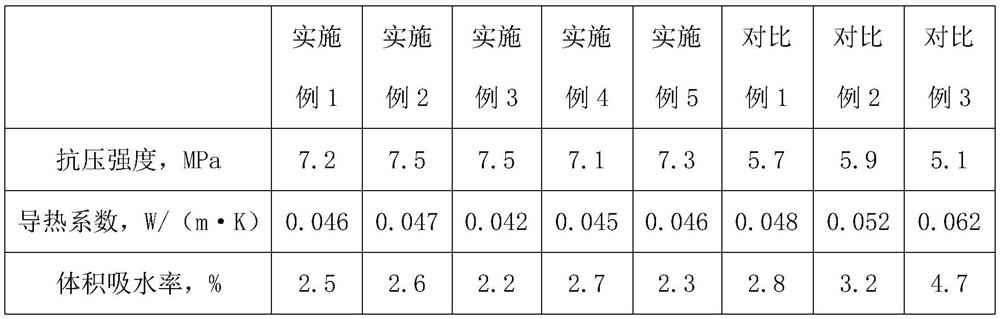

Examples

Embodiment 1

[0020] A prefabricated building thermal insulation wallboard, comprising the following raw materials in parts by weight: 70 parts of cement, 50 parts of high-calcium fly ash, 30 parts of quartz sand powder, 10 parts of polyacrylate emulsion, 6 parts of root fiber, 5 parts of polyvinyl acetate emulsion, 5 parts of sodium polyacrylate, 10 parts of magnesium aluminum silicate, 8 parts of oxidized polyethylene wax, 2 parts of potassium methyl silicate, 2 parts of divinylbenzene, 10 parts of activated carbon powder, carbon dioxide 6 parts of silicon, 8 parts of tiger eye evergreen bulb extract, 2 parts of nonylphenol polyoxyethylene ether, 8 parts of water reducing agent.

[0021] Wherein, the magnesium aluminum silicate is hydrophobic magnesium aluminum silicate.

[0022] In this embodiment, the steps of the preparation method of the prefabricated building thermal insulation wallboard are as follows:

[0023] 1) Mix cement, high-calcium fly ash, quartz sand powder, polyacrylate e...

Embodiment 2

[0029] A prefabricated building thermal insulation wallboard, comprising the following raw materials in parts by weight: 75 parts of cement, 55 parts of high-calcium fly ash, 35 parts of quartz sand powder, 12 parts of polyacrylate emulsion, 7 parts of root fiber, 6 parts of polyvinyl acetate emulsion, 6 parts of sodium polyacrylate, 12 parts of magnesium aluminum silicate, 14 parts of oxidized polyethylene wax, 4 parts of potassium methyl silicate, 4 parts of divinylbenzene, 18 parts of activated carbon powder, carbon dioxide 10 parts of silicon, 12 parts of tiger eye evergreen bulb extract, 3.5 parts of nonylphenol polyoxyethylene ether, 11 parts of water reducer.

[0030] Wherein, the magnesium aluminum silicate is hydrophobic magnesium aluminum silicate.

[0031] In this embodiment, the steps of the preparation method of the prefabricated building thermal insulation wallboard are as follows:

[0032] 1) Mix cement, high-calcium fly ash, quartz sand powder, polyacrylate em...

Embodiment 3

[0038] A prefabricated building thermal insulation wallboard, comprising the following raw materials in parts by weight: 80 parts of cement, 60 parts of high-calcium fly ash, 40 parts of quartz sand powder, 15 parts of polyacrylate emulsion, 8 parts of root fiber of horsetail, 7 parts of polyvinyl acetate emulsion, 8 parts of sodium polyacrylate, 15 parts of magnesium aluminum silicate, 12 parts of oxidized polyethylene wax, 3.5 parts of potassium methyl silicate, 3.5 parts of divinylbenzene, 15 parts of activated carbon powder, 9 parts of silicon, 10 parts of tiger eye evergreen bulb extract, 3 parts of nonylphenol polyoxyethylene ether, 10 parts of water reducing agent.

[0039] Wherein, the magnesium aluminum silicate is hydrophobic magnesium aluminum silicate.

[0040] In this embodiment, the steps of the preparation method of the prefabricated building thermal insulation wallboard are as follows:

[0041] 1) Mix cement, high-calcium fly ash, quartz sand powder, polyacryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com