An expanded perlite-sio 2 Preparation method of airgel lightweight thermal insulation wall material

A technology of expanded perlite and thermal insulation wall, applied in the field of building materials, can solve the problems of high compressive strength, low compressive strength, low water absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

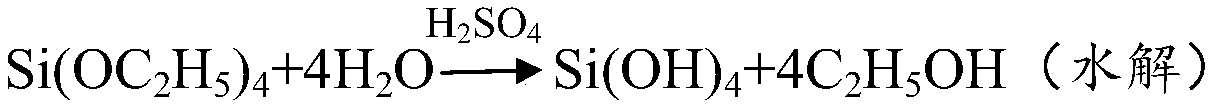

[0037] (1) With TEOS as precursor, EtOH as solvent, H 2 SO 4 and NH 3 ·H 2 O is the catalyst. Under continuous stirring, stir and mix TEOS and EtOH with a molar ratio of 1:5, and then add purified water and H 2 SO 4 , adjust the pH of the mixed solution system to 2.5, after stirring for 30 hours, add NH 3 ·H 2 O and purified water, adjust the pH of the mixed solution system to be 6;

[0038] (2) Heating the perlite at a high temperature of 1200°C to obtain expanded perlite, adding the expanded perlite to the SiO obtained in step (1) 2 In the sol, stir until the sol turns into a gel;

[0039] (3) Soak the gel obtained in step (2) in 100% distilled water for 24 hours, then soak it in 50% ethanol aqueous solution for 24 hours, and finally soak it in 100% ethanol for 24 hours. The temperature of the whole process control system is 38 degrees;

[0040] (4) Soak the gel obtained in step (3) in a 1:5:5 TMCS: EtOH: n-hexane mixed solution for 24 hours, then soak it in a 1:7 TM...

Embodiment 2

[0044] (1) With TEOS as precursor, EtOH as solvent, H 2 SO 4 and NH 3 ·H 2 O is the catalyst, under continuous stirring, stir and mix TEOS and EtOH with a molar ratio of 0.5:6, and then add purified water and H 2 SO 4 , adjust the pH of the mixed solution system to 3.5, after stirring for 24 hours, add NH 3 ·H 2 O and purified water, adjust the pH of the mixed solution system to be 7.5;

[0045] (2) Heating the perlite at a high temperature of 1000°C to obtain expanded perlite, adding the expanded perlite to the SiO obtained in step (1) 2 In the sol, stir until the sol turns into a gel;

[0046] (3) soak the gel obtained in step (2) in 100% distilled water for 30 hours, then soak in 50% ethanol aqueous solution for 30 hours, and finally soak in 100% ethanol for 30 hours, and the temperature of the whole process control system is 40 degrees;

[0047] (4) Soak the gel obtained in step (3) in a molar ratio of 0.5:4:3 in TMCS:EtOH:n-hexane mixed solution for 20 hours, then...

Embodiment 3

[0051] (1) With TEOS as precursor, EtOH as solvent, H 2 SO 4 and NH 3 ·H 2 O is the catalyst, under continuous stirring, stir and mix TEOS and EtOH with a molar ratio of 1.5:4, and then add purified water and H 2 SO 4 , adjust the pH of the mixed solution system to 3, after stirring for 30 hours, add NH 3 ·H 2 O and purified water, adjust the pH of the mixed solution system to be 8;

[0052] (2) Heating the perlite at a high temperature of 1300°C to obtain expanded perlite, adding the expanded perlite to the SiO obtained in step (1) 2 In the sol, stir until the sol turns into a gel;

[0053] (3) soak the gel obtained in step (2) in 100% distilled water for 20 hours, then soak in 50% ethanol aqueous solution for 20 hours, and finally soak in 100% ethanol for 20 hours, and the temperature of the whole process control system is 25 degrees;

[0054] (4) Soak the gel obtained in step (3) in a 1.5:6:5 TMCS: EtOH: n-hexane mixed solution for 30 hours, then soak it in a 1:10 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com