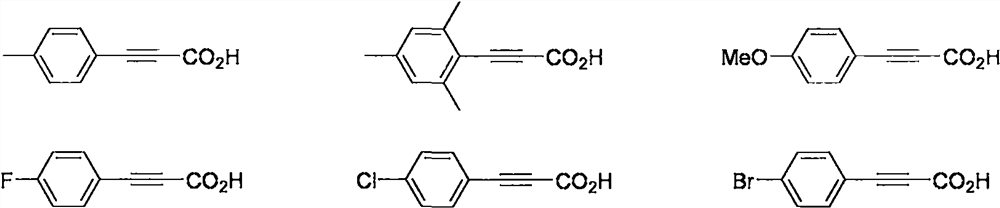

Synthesis method of 1-arylacetylene seleno-3-phenoxy-2-propanol compound

A synthesis method and phenoxy technology, applied in the field of organic compound synthesis, can solve the problems of pre-preparation, narrow substrate range, poor functional group tolerance, etc., and achieve the effects of simple post-processing, high yield and purity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

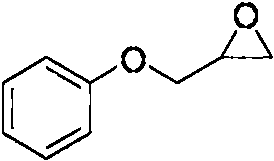

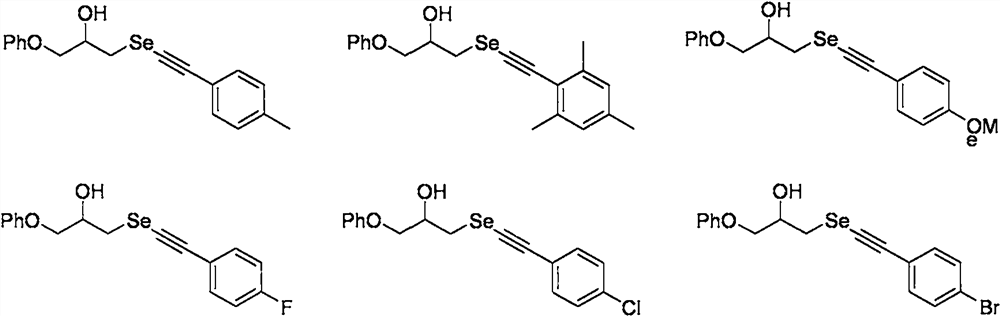

[0031] Synthesis of 1-(4-methylphenylacetylene selenyl)-3-phenoxy-2-propanol

[0032]

[0033] At room temperature, 4-methylphenylpropynoic acid (0.2mmol), elemental selenium (0.6mmol), phenyl glycidyl ether (0.6mmol), copper chloride (0.02mmol), 1,10-phenanthro Phenyl (0.02mmol), cesium carbonate (0.6mmol), tetrabutylammonium iodide (0.4mmol) and 2mL water were stirred at a reaction temperature of 50°C for 24h. After the reaction is over, add ethyl acetate to dilute, transfer the diluted solution to a separatory funnel for extraction, separate the aqueous phase and the organic phase, then extract the aqueous phase with ethyl acetate for 3 times, combine the organic phases, and add 5g of anhydrous sulfuric acid Sodium, stand still for 30min, wash the filter cake 3 times with 5mL ethyl acetate each time, then spin off the solvent, and obtain the product through column chromatography (eluent: sherwood oil: ethyl acetate=20: 1), the product is Light yellow solid with a meltin...

Embodiment 2

[0041] Synthesis of 1-(2,4,6-trimethylphenylethynylselenyl)-3-phenoxy-2-propanol

[0042]

[0043]At room temperature, 2,4,6-trimethylphenylpropynoic acid (0.2mmol), elemental selenium (0.6mmol), phenyl glycidyl ether (0.6mmol), copper chloride (0.02mmol), 1, 10-Phenanthroline (0.02mmol), cesium carbonate (0.6mmol), tetrabutylammonium iodide (0.4mmol) and 2mL water were stirred at a reaction temperature of 50°C for 24h. After the reaction is over, add ethyl acetate to dilute, transfer the diluted solution to a separatory funnel for extraction, separate the aqueous phase and the organic phase, then extract the aqueous phase with ethyl acetate for 3 times, combine the organic phases, and add 5g of anhydrous sulfuric acid Sodium, stand still for 30min, wash the filter cake 3 times with 5mL ethyl acetate each time, then spin off the solvent, and obtain the product through column chromatography (eluent: sherwood oil: ethyl acetate=20: 1), the product is Pale yellow liquid, yiel...

Embodiment 3

[0051] Synthesis of 1-(4-methoxyphenylacetylene selenyl)-3-phenoxy-2-propanol compound

[0052]

[0053] At room temperature, 4-methoxyphenylpropynoic acid (0.2mmol), elemental selenium (0.6mmol), phenyl glycidyl ether (0.6mmol), copper chloride (0.02mmol), 1,10-phenanthrene Roline (0.02mmol), cesium carbonate (0.6mmol), tetrabutylammonium iodide (0.4mmol) and 2mL water were stirred at a reaction temperature of 50°C for 24h. After the reaction is over, add ethyl acetate to dilute, transfer the diluted solution to a separatory funnel for extraction, separate the aqueous phase and the organic phase, then extract the aqueous phase with ethyl acetate for 3 times, combine the organic phases, and add 5g of anhydrous sulfuric acid Sodium, stand still for 30min, wash the filter cake 3 times with 5mL ethyl acetate each time, then spin off the solvent, and obtain the product through column chromatography (eluent: sherwood oil: ethyl acetate=20: 1), the product is Light yellow solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com