Method for constructing zinc ion hybrid supercapacitor based on eutectic solvent electrolyte

A technology of deep eutectic solvent and supercapacitor, which is applied in hybrid capacitor electrolyte, hybrid/electric double layer capacitor manufacturing, etc., to achieve the effect of price security, avoiding short circuit, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Zinc anode preparation: Polish the commercial zinc sheet (about 2mm) to remove the oxide layer on the surface;

[0030] (2) Preparation of porous carbon cathode: the commercial porous carbon (S BET ≈1900m 2 g -1 ) and the binder are uniformly mixed in a mass ratio of 90:10, and then the mixture is rolled into a thin sheet, and the sheet is pressed into a circular electrode sheet with a diameter of 12mm by a press.

[0031] (3) Preparation of deep eutectic solvent electrolyte: ZnCl 2 Mix evenly with ethylene glycol at a molar ratio of 1:2, heat at 90°C for 2 hours, and cool to room temperature naturally, then follow ZnCl 2 Add 1,2 dichloroethane to the above solution in a molar ratio of 1:6 to 1,2 dichloroethane, stir for 30 minutes to form ZnCl 2 / ethylene glycol / 1,2-dichloroethane deep eutectic solvent electrolyte.

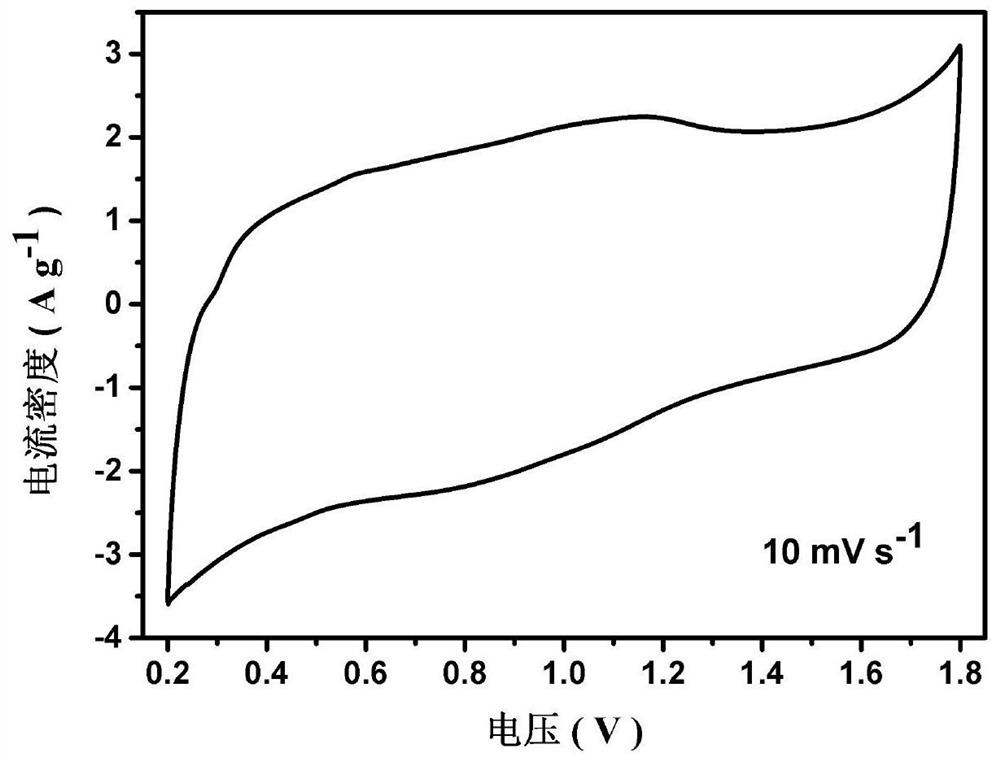

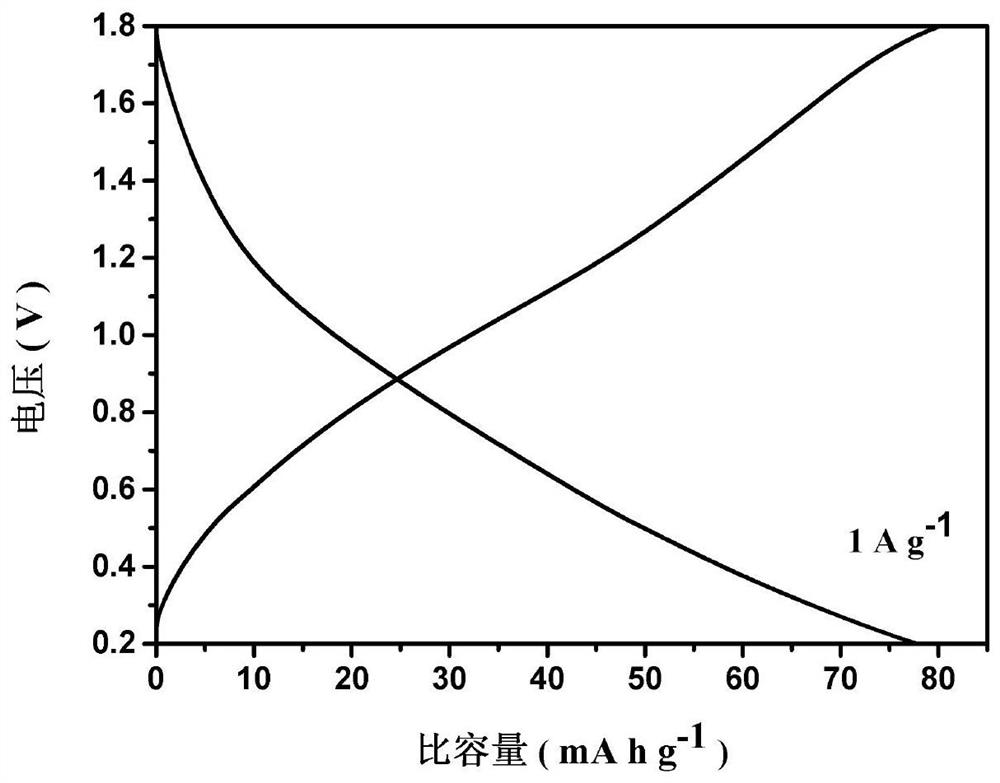

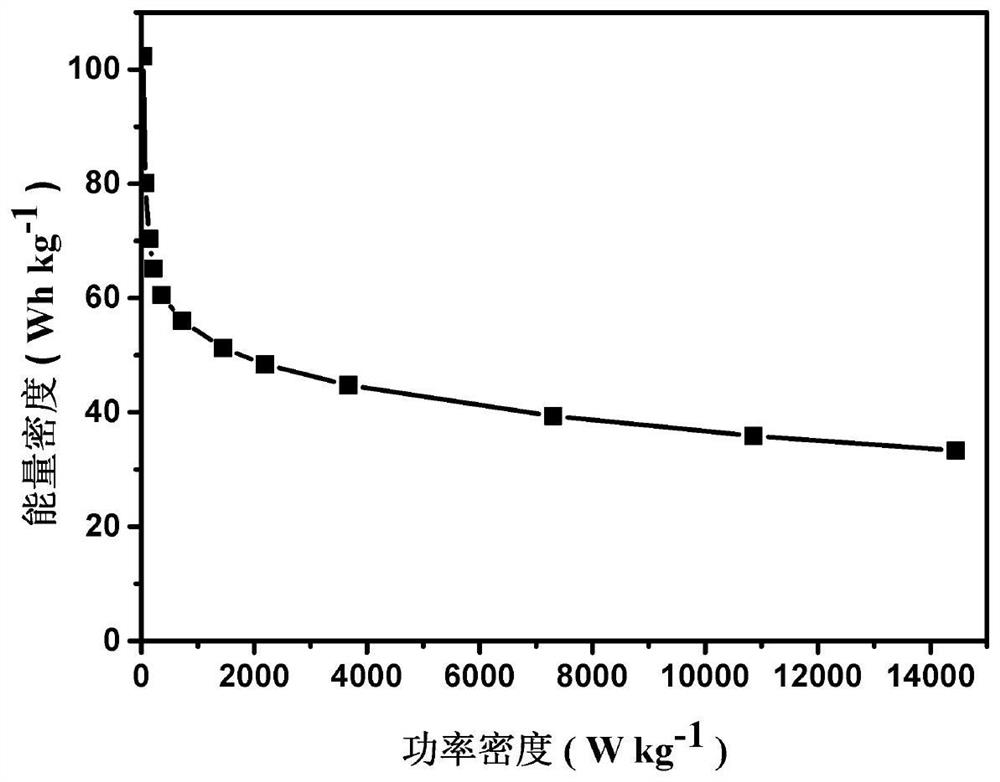

[0032] (4) Zinc-ion hybrid supercapacitors were assembled sequentially by zinc sheets, separators (dropped with deep eutectic solvent electrolyte...

Embodiment 2

[0034] (1) Zinc anode preparation: Polish the commercial zinc sheet (about 2mm) to remove the oxide layer on the surface;

[0035] (2) Preparation of porous carbon cathode: the commercial porous carbon (S BET ≈1900m 2 g -1 ) and the binder are uniformly mixed in a mass ratio of 90:10, and then the mixture is rolled into a thin sheet, and the sheet is pressed into a circular electrode sheet with a diameter of 12mm by a press.

[0036] (3) Preparation of deep eutectic solvent electrolyte: ZnCl 2 Mix well with urea at a molar ratio of 1:3, heat at 100°C for 2 hours, and cool to room temperature naturally, then follow ZnCl 2 Add 1,2 dichloroethane to the above solution in a molar ratio of 1:8 to 1,2 dichloroethane, stir for 30 minutes to form ZnCl 2 / urea / 1,2-dichloroethane deep eutectic solvent electrolyte.

[0037] (4) Zinc-ion hybrid supercapacitors were assembled sequentially by zinc sheets, separators (dropped with deep eutectic solvent electrolyte), and porous carbon ca...

Embodiment 3

[0039] (1) Zinc anode preparation: Polish the commercial zinc sheet (about 2mm) to remove the oxide layer on the surface;

[0040] (2) Preparation of porous carbon cathode: the commercial porous carbon (S BET ≈1900m 2 g -1 ) and the binder are uniformly mixed in a mass ratio of 90:10, and then the mixture is rolled into a thin sheet, and the sheet is pressed into a circular electrode sheet with a diameter of 12mm by a press.

[0041] (3) Preparation of deep eutectic solvent electrolyte: ZnCl 2 Mix evenly with acetamide at a molar ratio of 1:5, heat at 110°C for 4 hours, and cool to room temperature naturally, then follow ZnCl 2 Add dimethyl carbonate to the above solution in a molar ratio of 1:10 to dimethyl carbonate, stir for 30min to form ZnCl 2 / acetamide / dimethyl carbonate deep eutectic solvent electrolyte.

[0042] (4) Zinc-ion hybrid supercapacitors were assembled sequentially by zinc sheets, separators (dropped with deep eutectic solvent electrolyte), and porous c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com