Preparation method of high flux loose hollow fiber nanofiltration membrane

A high-flux, nanofiltration membrane technology, applied in the field of filtration membranes, can solve the problems of limited permeation performance improvement of nanofiltration membranes, poor organic/inorganic interface compatibility, and defects in ultra-thin separation layers. Poor tolerance, accelerated interfacial polymer process, effect of reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

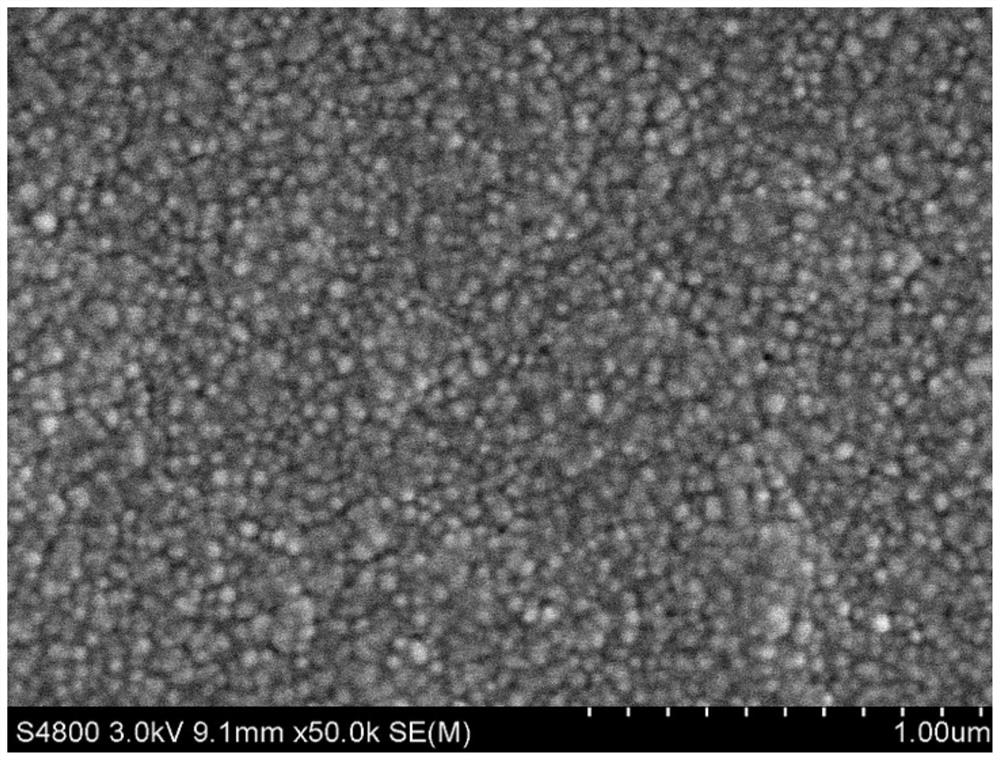

Embodiment 1

[0031] Film-making environmental conditions: temperature 25±3°C, humidity 45%±5.

[0032] (1) Weigh 0.0169g of silver nitrate and dissolve it in 100ml of deionized water, then add 0.6g of ethylenediamine dropwise to the silver nitrate solution, and stir to obtain an aqueous phase solution;

[0033] (2) Soak the polysulfone hollow fiber ultrafiltration membrane in the prepared aqueous phase solution, soak for 1min, and dry the residual solution on the surface of the ultrafiltration membrane with filter paper after taking it out;

[0034] (3) Weigh 0.01g of trimesoyl chloride and dissolve it in 100ml of n-hexane to obtain an oil phase solution, soak the hollow fiber ultrafiltration membrane obtained in step (2) into the oil phase solution, take it out after reacting for 15s, and place it in an oven , at 50°C for 10s;

[0035] (4) Take 1g of ammonium carbonate and dissolve it in 100ml deionized water, take out the membrane obtained in step (3) after soaking in ammonium carbonate...

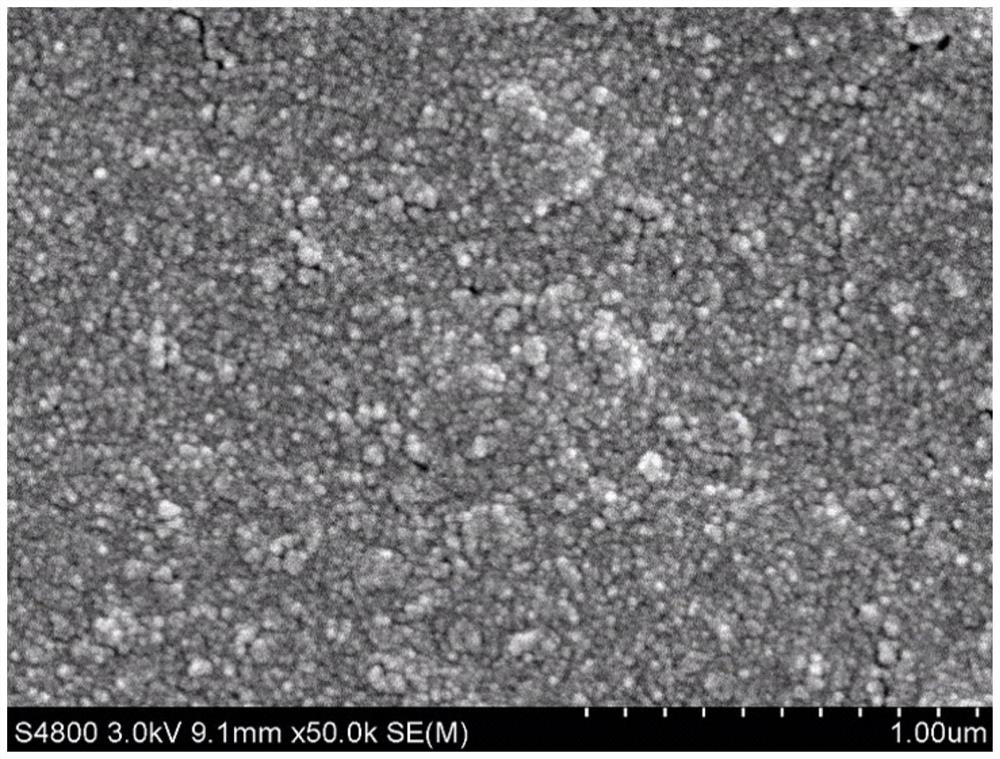

Embodiment 2

[0039] Film-making environmental conditions: temperature 25±3°C, humidity 45%±5.

[0040] (1) Take 0.204g of silver perchlorate and dissolve it in 100ml of deionized water, then add 3g of ethylenediamine dropwise to the silver perchlorate solution, and stir to obtain an aqueous phase solution;

[0041] (2) Soak the polyethersulfone hollow fiber ultrafiltration membrane in the prepared aqueous phase solution, soak for 5min, and dry the residual solution on the surface of the ultrafiltration membrane with filter paper after taking it out;

[0042] (3) Take by weighing 0.1g terephthaloyl chloride and dissolve in 100ml n-heptane to obtain an oil phase solution, soak the hollow fiber ultrafiltration membrane obtained in step (2) into the oil phase solution, take it out after reacting for 60s, and place In an oven, process at 80°C for 50s;

[0043] (4) Weigh 5 g of sodium thiosulfate and dissolve it in 100 ml of deionized water, soak the membrane obtained in step (3) in sodium thio...

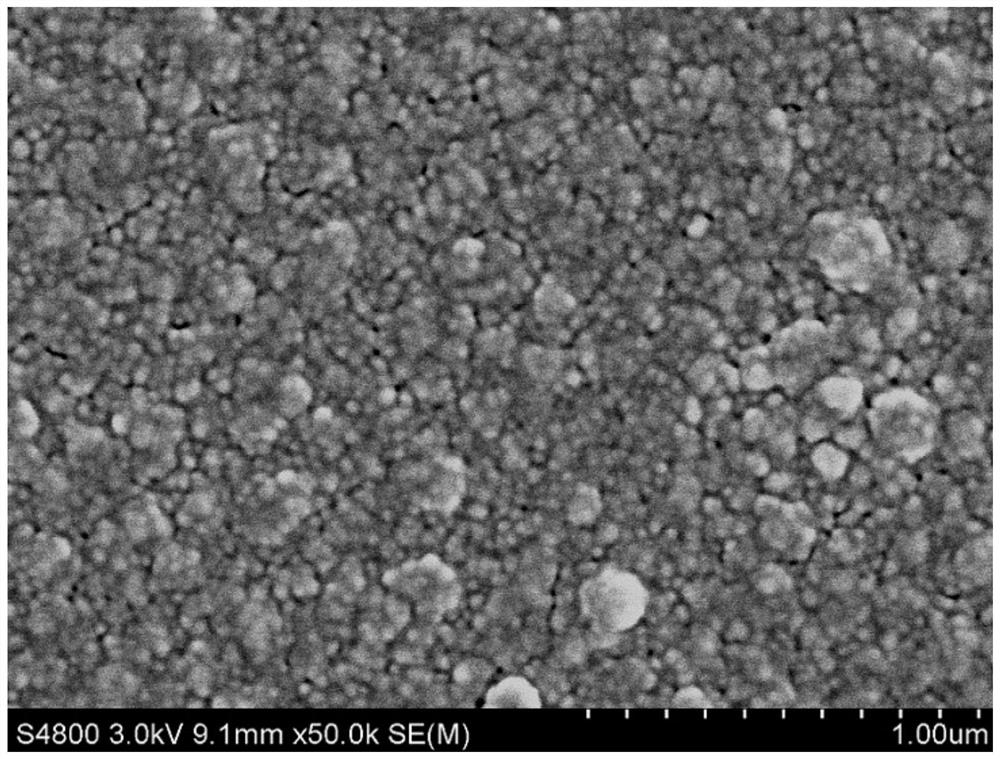

Embodiment 3

[0047] Film-making environmental conditions: temperature 25±3°C, humidity 45%±5.

[0048] (1) Take 0.485g of silver perchlorate and dissolve it in 100ml of deionized water, then add 3g of ethylenediamine dropwise to the silver perchlorate solution, and stir to obtain an aqueous phase solution;

[0049] (2) Soak the polyvinyl chloride hollow fiber ultrafiltration membrane in the prepared aqueous phase solution, soak for 10min, and dry the residual solution on the surface of the ultrafiltration membrane with filter paper after taking it out;

[0050] (3) Weigh 1g of isophthaloyl chloride and dissolve it in 100ml cyclohexane to obtain an oil phase solution, soak the hollow fiber ultrafiltration membrane obtained in step (2) into the oil phase solution, take it out after reacting for 120s, and place In an oven, process at 120°C for 120s;

[0051] (4) Weigh 10 g of potassium thiocyanate and dissolve it in 100 ml of deionized water, soak the membrane obtained in step (3) in potassium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com