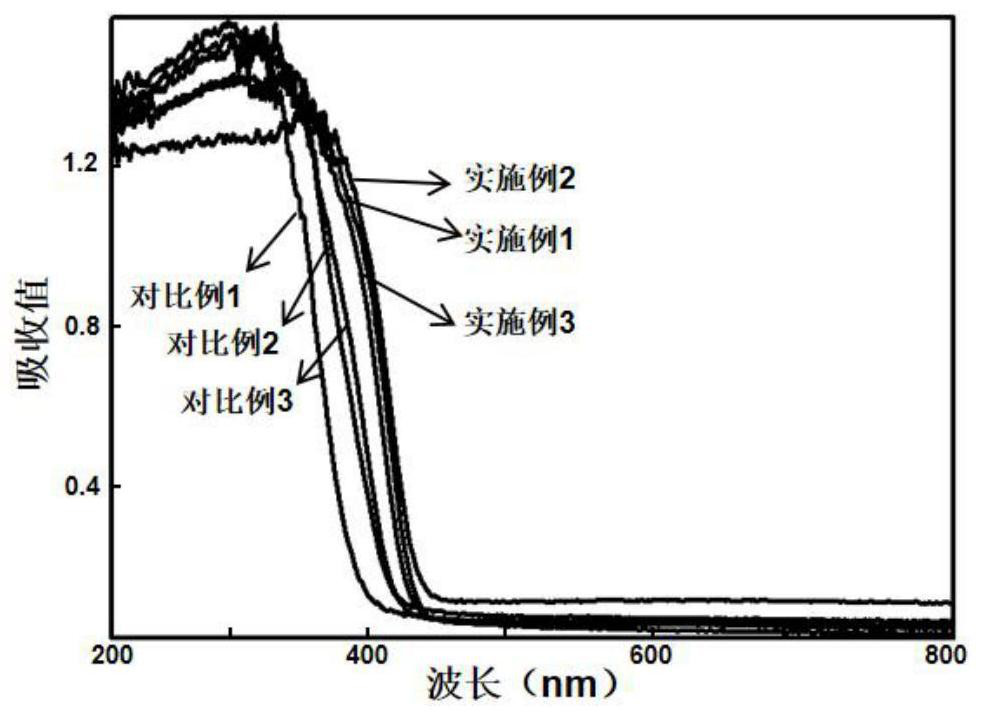

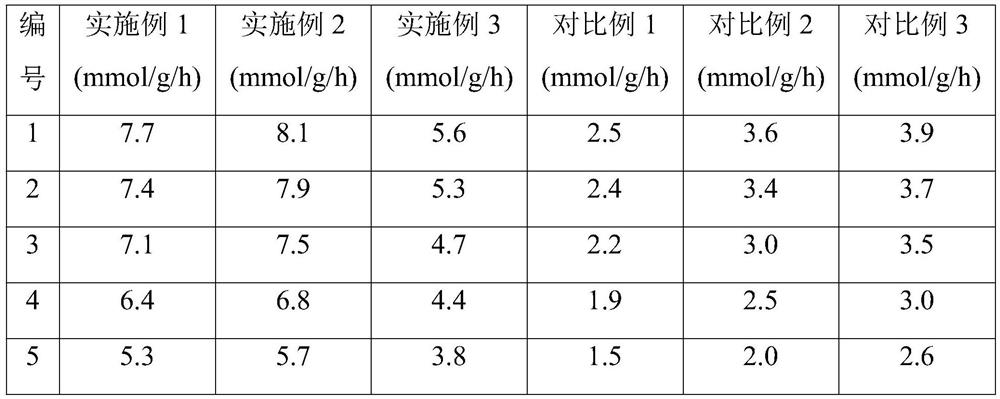

Preparation method of carbon quantum dot/titanium dioxide/molybdenum disulfide composite photocatalyst

A technology of molybdenum disulfide and titanium dioxide, which is applied in the field of photocatalysis, can solve the problems of poor interface binding effect, achieve high photocatalytic activity, excellent photocatalytic hydrogen production performance, and improve separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a carbon quantum dot / titanium dioxide / molybdenum disulfide composite photocatalyst with excellent photocatalytic hydrogen production performance, the specific steps are as follows:

[0024] (1) Preparation of carbon quantum dots: Mix 1g of urea and 10mL of polyethylene glycol evenly, then add 20mL of phosphoric acid, ultrasonicate 3 times, heat in a 300W microwave oven for 10min, and then use sodium hydroxide solution, deionized water and ethanol The mixture was washed separately and ultrasonically oscillated until the pH was neutral, filtered with a 0.22 μm ultrafiltration membrane, and finally dried in vacuum at 70°C;

[0025] (2) Preparation of molybdenum disulfide material: 2.4g sodium molybdate, 3g thioacetamide and 150mL ethylene glycol were added to the three-necked flask, then the three-necked flask was put into a microwave reactor, and nitrogen gas was fed into the three-necked flask. React at 180°C for 1 hour. After the reaction, wash, s...

Embodiment 2

[0029] A method for preparing a carbon quantum dot / titanium dioxide / molybdenum disulfide composite photocatalyst with excellent photocatalytic hydrogen production performance, the specific steps are as follows:

[0030] (1) Preparation of carbon quantum dots: Mix 1g of urea and 10mL of polyethylene glycol evenly, then add 20mL of phosphoric acid, ultrasonicate 3 times, heat in a 300W microwave oven for 10min, and then use sodium hydroxide solution, deionized water and ethanol The mixture was washed separately and ultrasonically oscillated until the pH was neutral, filtered with a 0.22 μm ultrafiltration membrane, and finally dried in vacuum at 70°C;

[0031] (2) Preparation of molybdenum disulfide material: 2.4g sodium molybdate, 3g thioacetamide and 150mL ethylene glycol were added to the three-necked flask, then the three-necked flask was put into a microwave reactor, and nitrogen gas was fed into the three-necked flask. React at 180°C for 1 hour. After the reaction, wash, s...

Embodiment 3

[0035] A method for preparing a carbon quantum dot / titanium dioxide / molybdenum disulfide composite photocatalyst with excellent photocatalytic hydrogen production performance, the specific steps are as follows:

[0036] (1) Preparation of carbon quantum dots: mix 1g of urea and 10mL of polyethylene glycol evenly, then add 30mL of phosphoric acid, after ultrasonication 3 times, heat in a 300W microwave oven for 10min, then use sodium hydroxide solution, deionized water and ethanol The mixture was washed separately and ultrasonically oscillated until the pH was neutral, filtered with a 0.22 μm ultrafiltration membrane, and finally dried in vacuum at 70°C;

[0037] (2) Preparation of molybdenum disulfide material: 2.4g sodium molybdate, 3g thioacetamide and 150mL ethylene glycol were added to the three-necked flask, then the three-necked flask was put into a microwave reactor, and nitrogen gas was fed into the three-necked flask. React at 180°C for 1 hour. After the reaction, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com