Preparation method of continuously synthesized rubber vulcanization accelerator CBS

A technology of vulcanization accelerator and synthetic rubber, applied in chemical instruments and methods, organic chemistry, chemical/physical process, etc., can solve the problems of difficult recovery of cyclohexylamine, high activity of hydrogen peroxide, large salt-containing wastewater, etc. The effect of phase mass transfer rate, environmental protection, and reaction rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

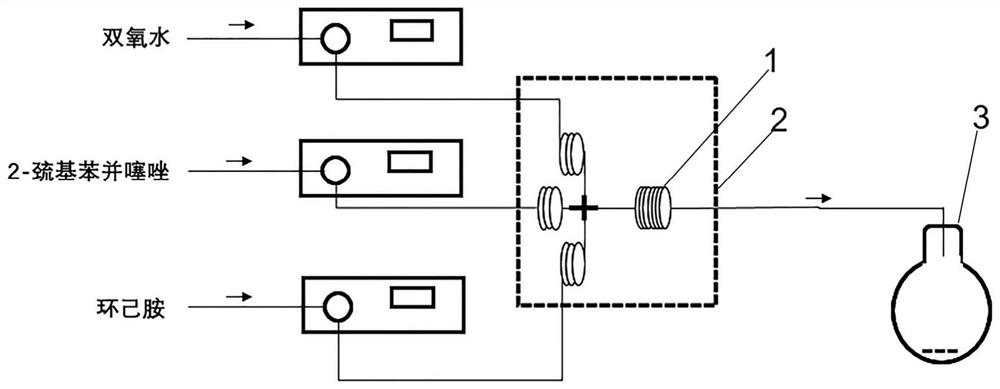

[0035] A preparation method for continuously synthesizing a rubber vulcanization accelerator CBS, utilizing a capillary microreactor to continuously synthesize a rubber vulcanization accelerator CBS under ultrasonic action, which specifically includes the following steps:

[0036] Step 1, completely dissolve 2-mercaptobenzothiazole in organic solvent, the mass ratio of 2-mercaptobenzothiazole to organic solvent is 1:3~7, the mixing time of 2-mercaptobenzothiazole and organic solvent is 10min ~30min, stir evenly to obtain a mixture;

[0037] Step 2, according to 2-mercaptobenzothiazole: cyclohexylamine: H 2 o 2 The molar ratio is 1:1~3:1.5~4, and the mixed liquid, cyclohexylamine, and hydrogen peroxide in step 1 are fed into the capillary microreactor 1 through the micro mixer according to a certain feed rate for oxidation reaction, and the oxidation reaction time is 5s ~30s. The concentration of the hydrogen peroxide solution is 10wt%-20wt%, and the capillary microreactor 1...

Embodiment 2

[0041] A preparation method for continuously synthesizing a rubber vulcanization accelerator CBS, utilizing a capillary microreactor to continuously synthesize a rubber vulcanization accelerator CBS under ultrasonic action, which specifically includes the following steps:

[0042] Step 1, completely dissolve 2-mercaptobenzothiazole in organic solvent, the mass ratio of 2-mercaptobenzothiazole to organic solvent is 1:5, the mixing time of 2-mercaptobenzothiazole and organic solvent is 15min, stir Uniformly, a mixed solution is obtained;

[0043]Step 2, according to 2-mercaptobenzothiazole: cyclohexylamine: H 2 o 2 The molar ratio is 1:1.5:2.5. The mixed solution, cyclohexylamine, and hydrogen peroxide in step 1 are entered into the capillary microreactor 1 through the micro mixer according to a certain feed rate for oxidation reaction. The oxidation reaction time is 15s. Device 1 enters the capillary microreactor for oxidation reaction, wherein the concentration of hydrogen p...

Embodiment 3

[0047] A preparation method for continuously synthesizing a rubber vulcanization accelerator CBS, utilizing a capillary microreactor to continuously synthesize a rubber vulcanization accelerator CBS under ultrasonic action, which specifically includes the following steps:

[0048] Step 1, weigh 30g of 2-mercaptobenzothiazole and 150g of ethyl acetate, completely dissolve 2-mercaptobenzothiazole in methyl acetate, stir and mix at room temperature for 15min, stir evenly to obtain a mixed solution, and set aside;

[0049] Step 2, weigh 26.73g cyclohexylamine, 109.3g mass fraction of 12% hydrogen peroxide solution in two beakers, set aside; turn on the ultrasonic cleaner, immerse the capillary microreactor 1, the inner diameter of the capillary microreactor 1 It is 0.6mm and made of stainless steel. The temperature of the ultrasonic water bath 2 is controlled at 40°C, and then the mixture of 2-mercaptobenzothiazole and ethyl acetate, cyclohexylamine, and hydrogen peroxide solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com