Method for strengthening magnetic property of chromium-containing spinel synthesized from chromium-containing wastewater at normal temperature

A chromium spinel, normal temperature synthesis technology, applied in the field of resources and environment, can solve the problems of high processing cost and low utilization rate of ferrite method, and achieve the effect of improving resource utilization rate, reducing recycling cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

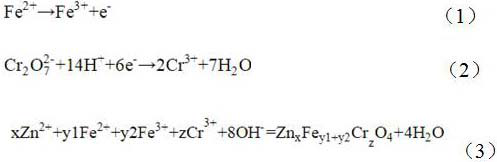

[0033] Example 1: Treatment of high-concentration electroplating chromium-containing wastewater

[0034] The valence state of chromium in the chromium-containing wastewater of an electroplating factory is mainly hexavalent, the concentration of chromium is 200mg / L, and the initial pH value of the wastewater is 1.6. First, gray cast iron powder is used for hexavalent chromium reduction. The particle size of iron powder is 0.15-0.23mm, the molar ratio of iron powder to hexavalent chromium is 30, and the hexavalent chromium reduction rate reaches over 99%. The reduced overflow wastewater enters the spinel synthesis pool, and zinc sulfate is added to the pool. The concentration of zinc ions is controlled at about 60mg / L, and the concentration ratio of zinc ions to chromium ions is 0.3, and then ferrous sulfate and ferrous sulfate are added. The molar ratio of iron to chromium ions is 16, then milk of lime is added to adjust the pH of the wastewater to 11, and the wastewater is aer...

Embodiment 2

[0035] Embodiment 2: Treatment of low-concentration electroplating chromium-containing wastewater

[0036] The wastewater from a hanger electroplating factory in Guangxi has a chromium concentration of 60mg / L, mainly hexavalent chromium, and the original pH value of the wastewater is 3.5. The pH is adjusted to 2.0 by sulfuric acid, and hexavalent chromium is reduced by using ferrous sulfate and sodium pyrosulfite, and the reduction rate of hexavalent chromium reaches more than 99%. The overflow wastewater after reduction enters the reaction tank, and zinc sulfate is added to the reaction tank so that the concentration of zinc ions is 6 mg / L, and the concentration ratio of zinc ions and chromium ions is 0.1, and then ferrous sulfate, ferrous sulfate and chromium are added The ion molar ratio is 8, then add slaked lime, adjust the pH of the wastewater to 9, aerate and stir with compressed air, the aeration rate is 80mL / min, and the stirring time is 1.0h. After the reaction is c...

Embodiment 3

[0037] Embodiment 3: processing of mineral processing chromium-containing wastewater

[0038] The concentration of chromium in the chromium-containing wastewater produced by a concentrator is 15mg / L, the chromium is mainly hexavalent chromium, and the initial pH of the wastewater is 7.5. Sulfuric acid is used to adjust the pH of wastewater to 1.0, sodium pyrosulfite is used to reduce hexavalent chromium to trivalent chromium, and the reduction rate of chromium can reach more than 99%. The overflow waste water after reduction enters the reaction tank, adds zinc chloride, makes the concentration ratio of zinc ion and chromium ion be 0.8, adds ferrous chloride, and the molar ratio of ferrous sulfate and chromium ion is 20, adds sodium hydroxide, adjusts The pH of the waste water is 13, and it is aerated and stirred by compressed air. The aeration rate is 50mL / min, and the stirring time is 0.5h. After the reaction is completed, the pulp is pumped into the magnetic separator for m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com