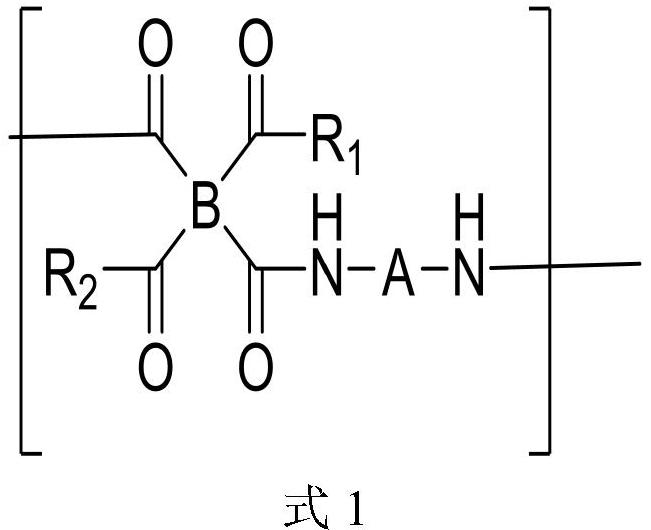

Liquid crystal aligning agent for preparing liquid crystal display element and application thereof

A technology of liquid crystal alignment agent and liquid crystal alignment film, which is applied in liquid crystal materials, optics, instruments, etc., and can solve problems such as inconsistent electric field strength, surface scratches, scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

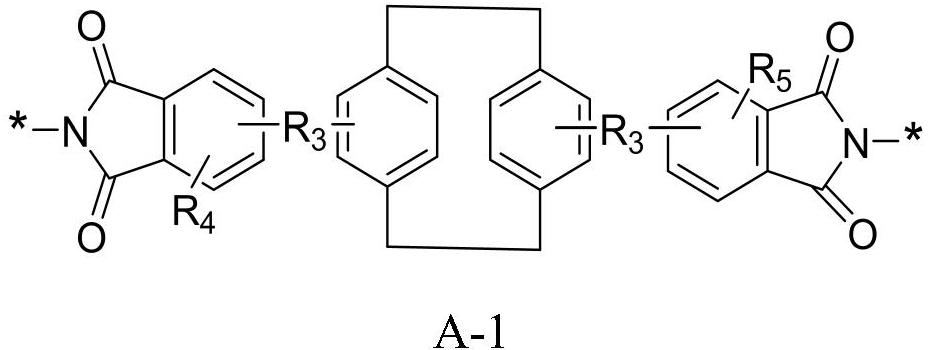

[0070] The preparation method of the diamine compound DA (A-1-1) represented by the structural unit A-1-1 is shown in the synthetic route 1:

[0071]

[0072] The specific operation process is:

[0073] (1) Synthesis of compound a-3

[0074] Drop into a-1 (28.34g, 110 mmol), a-2 (12.02g, 50 mmol), potassium carbonate (13.82g, 100 mmol) and DMF solvent 200mL in a 250mL three-neck round bottom flask, heat up and reflux React for 12 hours, cool down to room temperature, add the reaction solution into 1000 g of water, a large amount of light yellow solid precipitates, filter the solid, and rinse with 100 mL of water to obtain the crude compound a-3, which is recrystallized from a mixture of THF and ethanol, After filtering and drying, 25.6 light yellow solidified powder a-3 was obtained, and the yield was 75%.

[0075] (2) Synthesis of compound DA (A-1-1)

[0076] Put a-3 (20.48g, 30 mmol), 10g hydrazine hydrate (80%) and DMF solvent 200mL in a 250mL three-neck round bottom ...

Synthetic example 2~3

[0079] The diamine compounds DA (A-1-2) and DA (A-1-3) represented by "Formula A-1-2~Formula A-1-3" can be synthesized according to the synthesis route 1, and both can be used The corresponding parent compounds undergo Williamson etherification reaction, and then add hydrazine hydrate to synthesize the target diamine compounds DA (A-1-2) and DA (A-1-3). The structural formula is shown in the following formula DA (A-1-2) and DA (A-1-3), the high-resolution mass spectrometry results and elemental analysis results of the corresponding target compounds are shown in Table 1 below.

[0080]

[0081] Mass spectrum and elemental analysis data of each compound in Table 1 Synthesis Examples 2-3

[0082]

[0083]

[0084] The compound abbreviation used in the present embodiment and comparative example and the measuring method of each characteristic are as follows:

[0085] NMP: N-methyl-2-pyrrolidone

[0086] BC: Ethylene glycol monobutyl ether

[0087] DA(A-1-1):

[0088] ...

Embodiment 1

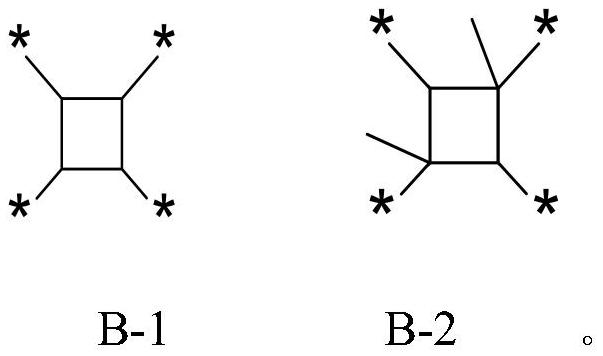

[0107] 500mL three-necked round-bottomed flask was ventilated and protected, and then the compounds DA(A-1-1) (5.61g, 10mmol), DA(A-2) (4.01g, 20mmol), DA(A -5) (2.16g, 20mmol) and NMP (81.18g), the reaction system was heated up to 80°C and kept for 0.5 hours to completely dissolve, and then DAH (B-1) (5.88g, 30mmol), DAH (B-1) were put into the system 2) (4.48g, 20mmol) and NMP (81.18g), keep the temperature at 80° C. for 6 hours, then cool down to room temperature to obtain polyamic acid polymer PA-1 with a concentration of 12%.

[0108] Dilution: Take 100 g of PA-1 polyamic acid solution, add 71.6 g of NMP and 68.4 g of BC, stir at room temperature for 2 hours, and then filter through a 0.2 μm filter membrane to obtain the liquid crystal alignment agent LCA-1 of Example 1. The polymer concentration in the liquid crystal aligning agent is 5.0%, and the solvent ratio is NMP:BC=70:30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com