Copper-copper oxide integrated negative electrode for lithium ion battery based on hollow tubular three-dimensional nanoporous structure and preparation method

A lithium-ion battery, three-dimensional nanotechnology, applied in the direction of battery electrodes, negative electrodes, structural parts, etc., can solve the problems of limited binding force between active components and copper foil, increased electrode polarization and impedance, active component shedding failure, etc. , to improve the comprehensive electrochemical performance, increase the contact area, and promote the effect of rapid transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

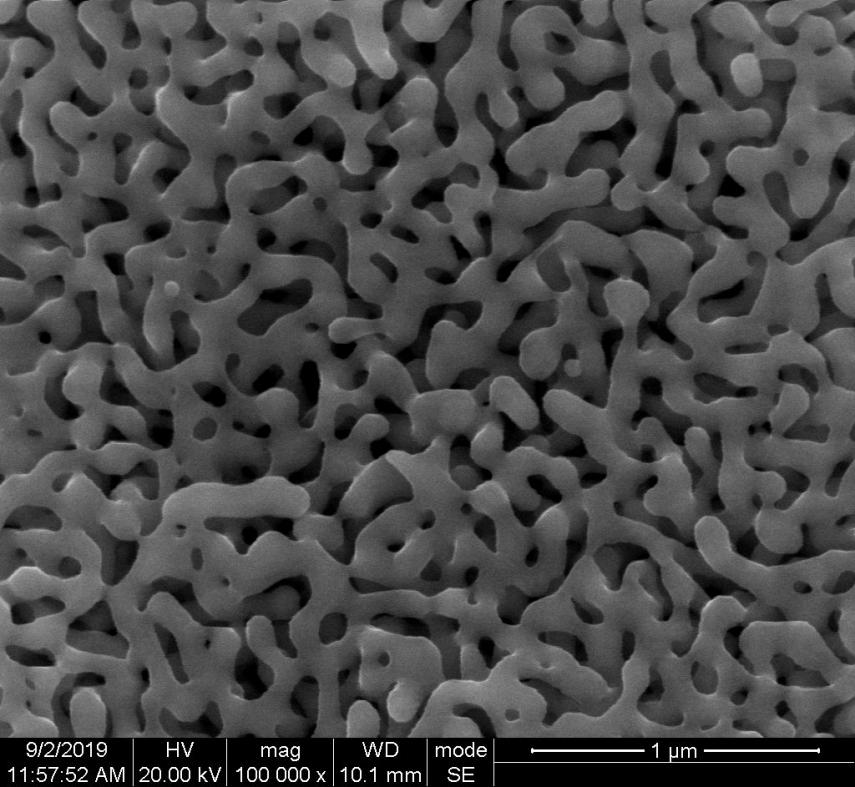

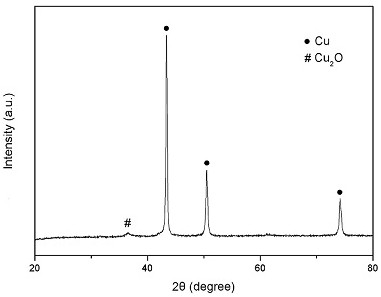

[0042] In this embodiment, a lithium-ion battery Cu-Cu based on a hollow tubular three-dimensional nanoporous structure is provided. 2 The preparation method of O integrated negative electrode. Proceed as follows.

[0043] (1) Weigh manganese and copper ingots according to the ratio of manganese to copper atomic ratio of 65:35, and smelt them in a muffle furnace to obtain manganese-copper alloy ingots. The manganese-copper alloy ingot was cut into manganese-copper alloy sheets with a thickness of 500 μm and a length and width of 7 mm with a wire cutting machine, and the manganese-copper alloy sheets were treated with 280 mesh, 800 mesh, 1500 mesh, and 2000 mesh water sandpaper in sequence. The surface is polished, and then polished with a metallographic sample polishing machine, and the polished manganese-copper alloy sheet is cleaned with deionized water. At room temperature, the ground sample was placed in 5 wt.% sulfuric acid solution for dealloying treatment. The dealloy...

Embodiment 2

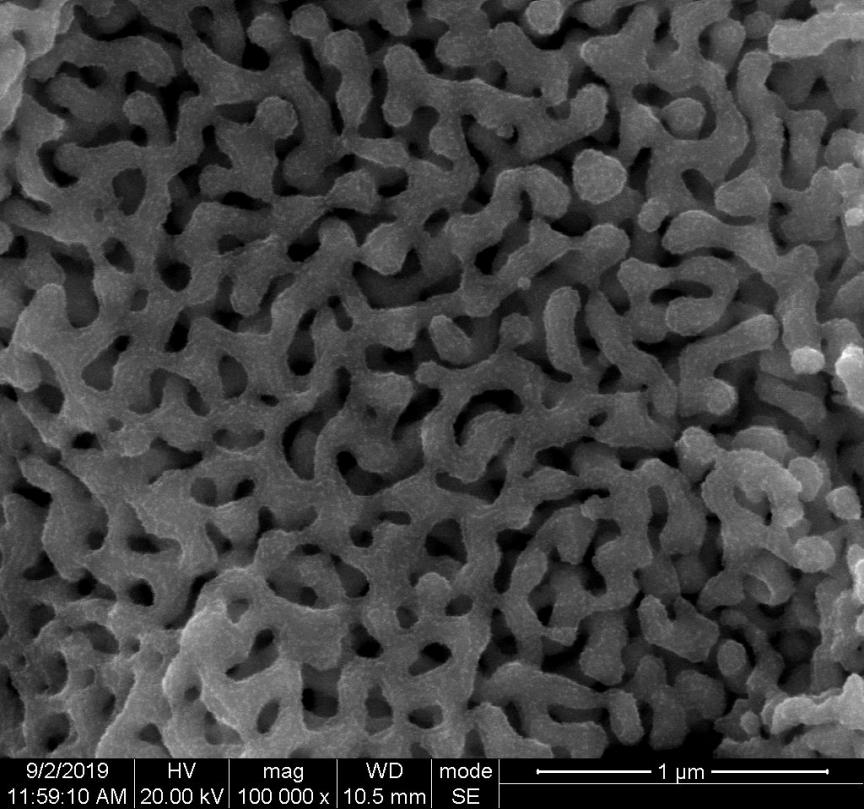

[0051] In this embodiment, a lithium-ion battery Cu-CuO / Cu based on a hollow tubular three-dimensional nanoporous structure is provided. 2 A method for preparing an O mixed membrane integrated negative electrode. Proceed as follows.

[0052] (1) According to the atomic ratio of manganese and copper of 60:40, the manganese and copper ingots were weighed and smelted in a muffle furnace to obtain manganese-copper alloy ingots. The manganese-copper alloy ingot was cut into manganese-copper alloy sheets with a thickness of 500 μm and a length and width of 7 mm with a wire cutting machine, and the manganese-copper alloy sheets were treated with 280 mesh, 800 mesh, 1500 mesh, and 2000 mesh water sandpaper in sequence. The surface is polished, and then polished with a metallographic sample polishing machine, and the polished manganese-copper alloy sheet is cleaned with deionized water. At room temperature, the ground sample was placed in 5 wt.% sulfuric acid solution for dealloying ...

Embodiment 3

[0060] In this embodiment, a lithium-ion battery Cu-CuO / Cu based on a hollow tubular three-dimensional nanoporous structure is provided. 2 A method for preparing an O mixed membrane integrated negative electrode. Proceed as follows.

[0061] (1) According to the atomic ratio of manganese and copper of 55:45, the manganese and copper ingots were weighed and smelted in a muffle furnace to obtain manganese-copper alloy ingots. The manganese-copper alloy ingot was cut into manganese-copper alloy sheets with a thickness of 500 μm and a length and width of 7 mm with a wire cutting machine, and the manganese-copper alloy sheets were treated with 280 mesh, 800 mesh, 1500 mesh, and 2000 mesh water sandpaper in sequence. The surface is polished, and then polished with a metallographic sample polishing machine, and the polished manganese-copper alloy sheet is cleaned with deionized water. At room temperature, the ground sample was placed in 5 wt.% sulfuric acid solution for dealloying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com