High-performance reversible solid oxide battery electrode material composition and preparation method thereof

A solid oxide, battery electrode technology, used in battery electrodes, fuel cells, circuits, etc., to achieve high performance, high output power, and battery performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

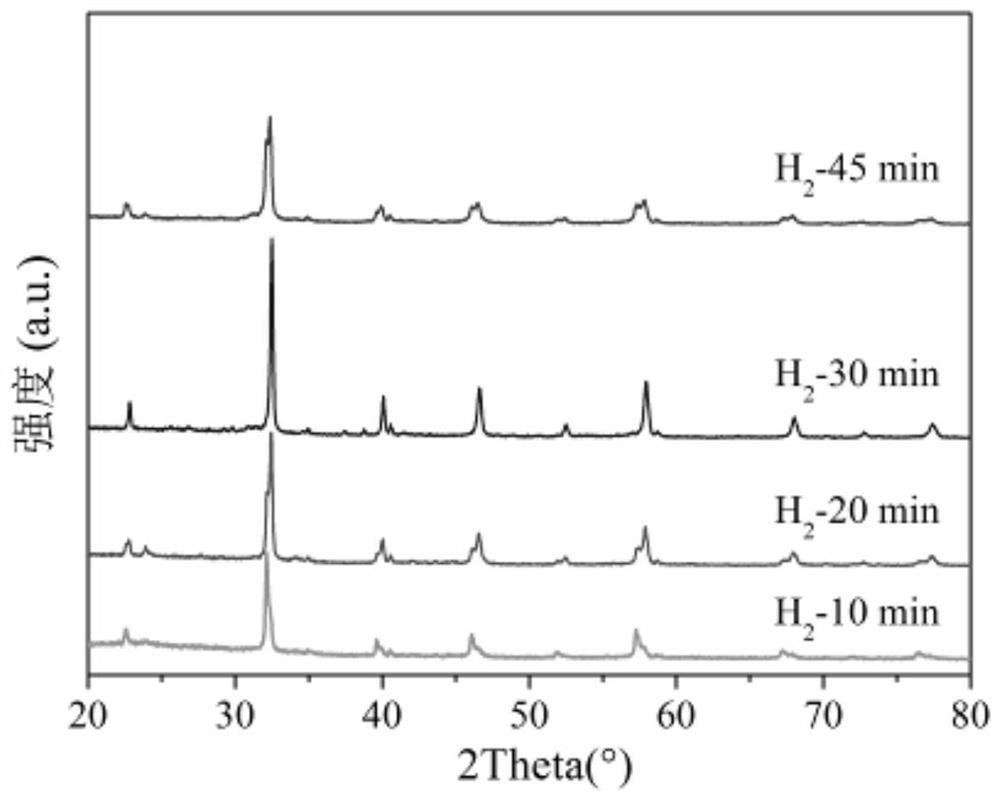

[0043] The invention relates to a high-performance solid oxide reversible battery electrode material composition and a preparation method thereof, belonging to the technical field of reversible solid oxide batteries. A composite porous hydrogen electrode composed of nickel oxide and yttria-stabilized zirconia (YSZ) was prepared by phase inversion casting method. This hydrogen electrode was composed of 60% NiO and 40% YSZ by mass fraction. Highly reactive towards hydrogen and resistant to CO 2 Poisoned PrBaMn 2 o 5+δ , in the oxygen ion conductor electrolyte YSZ and SrSc 0.175 Nb 0.025 co 0.8 o 3-δ When the oxygen electrode is used, the corresponding single cell can obtain 3.0 W cm in solid oxide fuel cell mode at 750 °C -2 Maximum output power; electrolysis of CO in solid oxide electrolysis cell mode 2 , can get -2.09 A cm at 1.3V -2 The maximum current density and remain stable in the long-term test. The invention develops a high-performance preparation method for a ...

Embodiment 1

[0046] This embodiment provides a method for preparing a hydrogen electrode for a high-performance reversible solid oxide battery that introduces a PBM nanoparticle-modified tape through an impregnation method. The specific steps are as follows:

[0047] Fabrication of porous NiO-YSZ hydrogen electrode casting sheets by phase transition casting method;

[0048] Weigh 4.3501g of Pr(NO 3 ) 3 •6H 2 O, 2.6134g of Ba(NO 3 ) 2 and 4.4214g of Mn(CH 3 OO) 2 • 4H 2 O was placed in a clean beaker, and 100 mL of deionized water was added and stirred and dissolved on an electric stirring table to obtain a clear solution;

[0049] Weigh 3.0028g of glycine complexing agent and add to the dissolved metal ion solution, so that the molar ratio of glycine to metal ion is 1:1. Then the solution was transferred to a 100 mL volumetric flask for constant volume, so that the obtained 0.1 mol L -1 dipping solution;

[0050] The PBM solution was impregnated into the non-reduced porous NiO-YS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com