Superfine oxide particle silver oxide ferroelectric contact material and preparation method thereof

A technology of oxide particles and electrical contact materials, applied in contacts, circuits, electric switches, etc., can solve the problems of inability to remove low-melting point impurity metals, high arc energy, and inability to effectively remove low-melting point impurity sodium, etc., to achieve improved Anti-arc burning characteristics, simple production process, and the effect of eliminating agglomeration defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

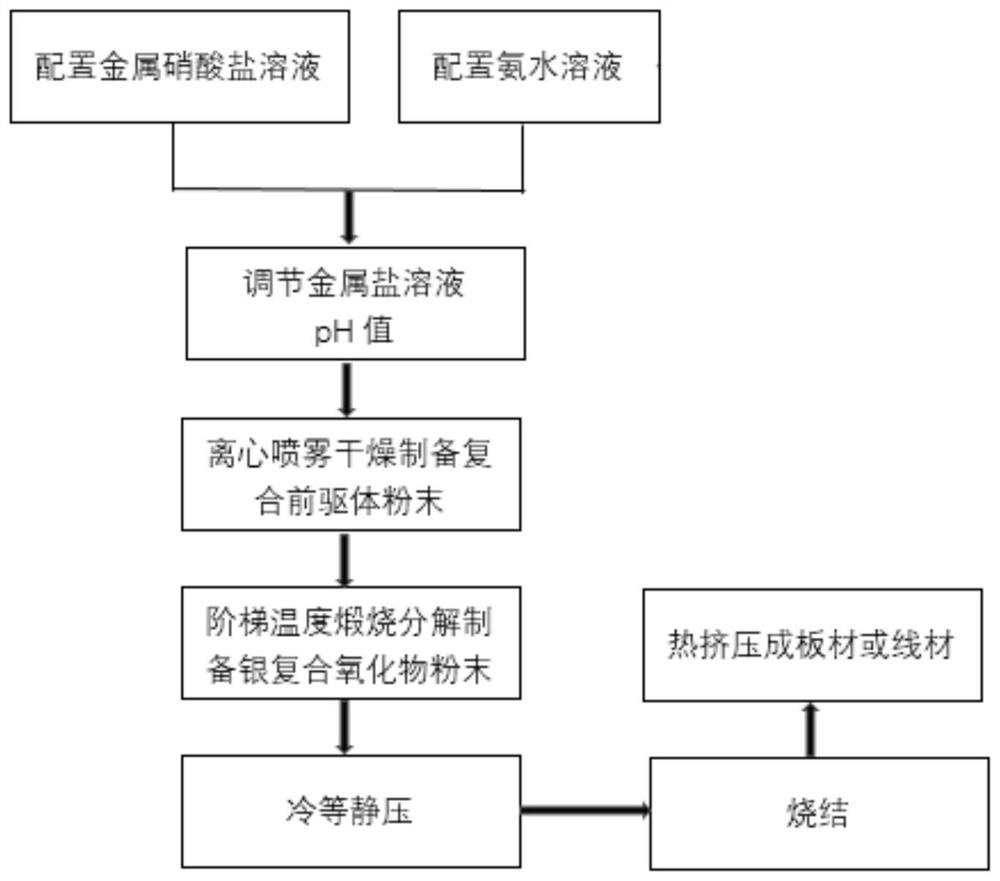

Method used

Image

Examples

Embodiment 1

[0035]This implementation case proceeds as follows:

[0036] 1) Ag:Fe by weight percentage 2 o 3 :MoO 3 =93.6:5.4:1 (the total weight is designed to be 10kg) to configure silver nitrate solution, ferric nitrate solution, and molybdenum nitrate solution. According to the requirements of total weight and weight percentage, configure 72.23L of silver nitrate solution with an initial solution solubility of 1.2mol / L, configure 13.5L of ferric nitrate solution with an initial solution solubility of 0.5mol / L, and configure an initial solution solubility of 0.1mol / L molybdenum nitrate solution 6.94L, prepare 50L ammonia solution with an initial solubility of 0.6mol / L.

[0037] 2) Mix the silver nitrate solution, ferric nitrate solution, and molybdenum nitrate solution prepared above, and adjust the pH of the mixed solution to 7.5 with the prepared ammonia solution.

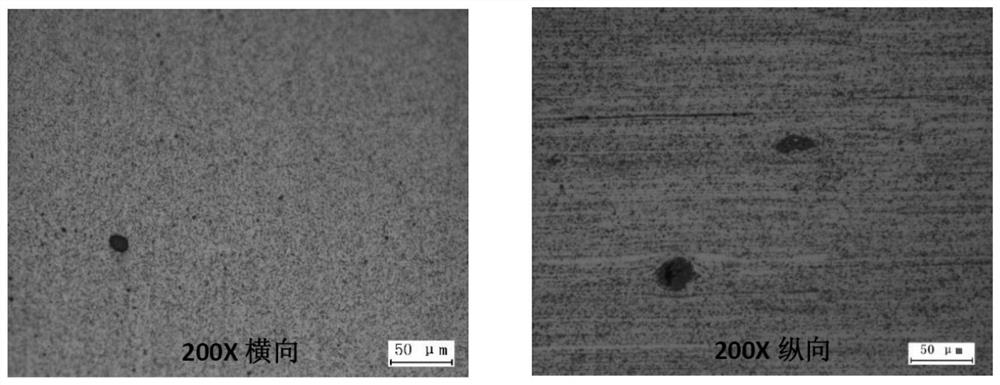

[0038] 3) The metal salt solution adjusted by pH is prepared on the spray drying equipment to prepare the composit...

Embodiment 2

[0046] This implementation case proceeds as follows:

[0047] 1) Ag:Fe by weight percentage 2 o 3 :Y 2 o 3 =93.6:5.4:1 (the total weight is designed to be 10kg) to configure silver nitrate solution, ferric nitrate solution, and yttrium nitrate solution. According to the requirements of total weight and weight percentage, configure 72.23L of silver nitrate solution with an initial solution solubility of 1.2mol / L, configure 13.5L of ferric nitrate solution with an initial solution solubility of 0.5mol / L, and configure an initial solution solubility of 0.1mol / L yttrium nitrate solution 8.85L, the configuration initial solubility is 0.6mol / L ammonia solution 50L.

[0048] 2) Mix the silver nitrate solution, ferric nitrate solution, and yttrium nitrate solution prepared above, and adjust the pH of the mixed solution to 7.5 with the prepared ammonia solution.

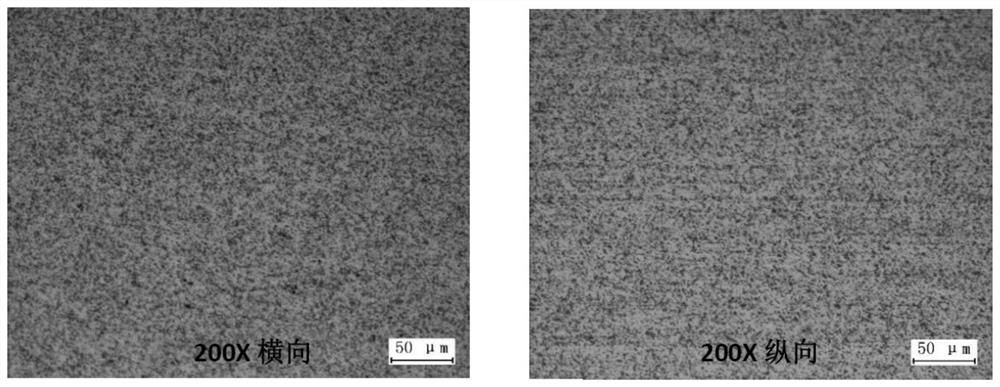

[0049] 3) The metal salt solution adjusted by batch pH is prepared on the spray drying equipment to prepare the compo...

Embodiment 3

[0057] This implementation case proceeds as follows:

[0058] 1) Ag:Fe by weight percentage 2 o 3 :La 2 o 3 =93.6:5.4:1 (the total weight is designed to be 10kg) to configure silver nitrate solution, ferric nitrate solution, and lanthanum nitrate solution. According to the requirements of total weight and weight percentage, configure 72.23L of silver nitrate solution with an initial solution solubility of 1.2mol / L, configure 13.5L of ferric nitrate solution with an initial solution solubility of 0.5mol / L, and configure an initial solution solubility of 0.1mol / L lanthanum nitrate solution 6.15L, the configuration initial solubility is 0.6mol / L ammonia solution 50L.

[0059] 2) Mix the above prepared silver nitrate solution, ferric nitrate solution and lanthanum nitrate solution evenly, and adjust the pH of the mixed solution to 7.5 with the prepared ammonia solution.

[0060] 3) The metal salt solution adjusted by pH is prepared on the spray drying equipment to prepare th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com