Control method for CMP rate selectivity of multi-layer copper interconnection barrier layer

A control method and technology of barrier layer, which can be used in manufacturing tools, water-based dispersants, grinding devices, etc., can solve problems such as difficult decomposition, and achieve the effects of simple ingredients, improved yield and yield, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

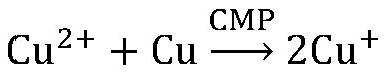

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take 250ml of silica sol with an abrasive mass fraction of 40%, the particle size is 50nm-90nm, and the dispersion is between ±3%; citric acid chelated copper 5g; potassium citrate 5g; FA / O II type chelating agent 0.5g . Fatty alcohol polyoxyethylene ether 3g, dodecylbenzenesulfonic acid 1g. The specific preparation method is as follows: first mix FA / O type II chelating agent, citric acid chelated copper, potassium citrate, fatty alcohol polyoxyethylene ether, dodecylbenzenesulfonic acid and add appropriate amount of ionized water, then add silicon In the sol, stir evenly by means of step-by-step mixing, and finally make up to 1000g with deionized water, and continue stirring evenly to obtain polishing solution S1.

[0045] Test monitoring: the pH value of the polishing solution is 9.5, and the particle size is 80-120nm.

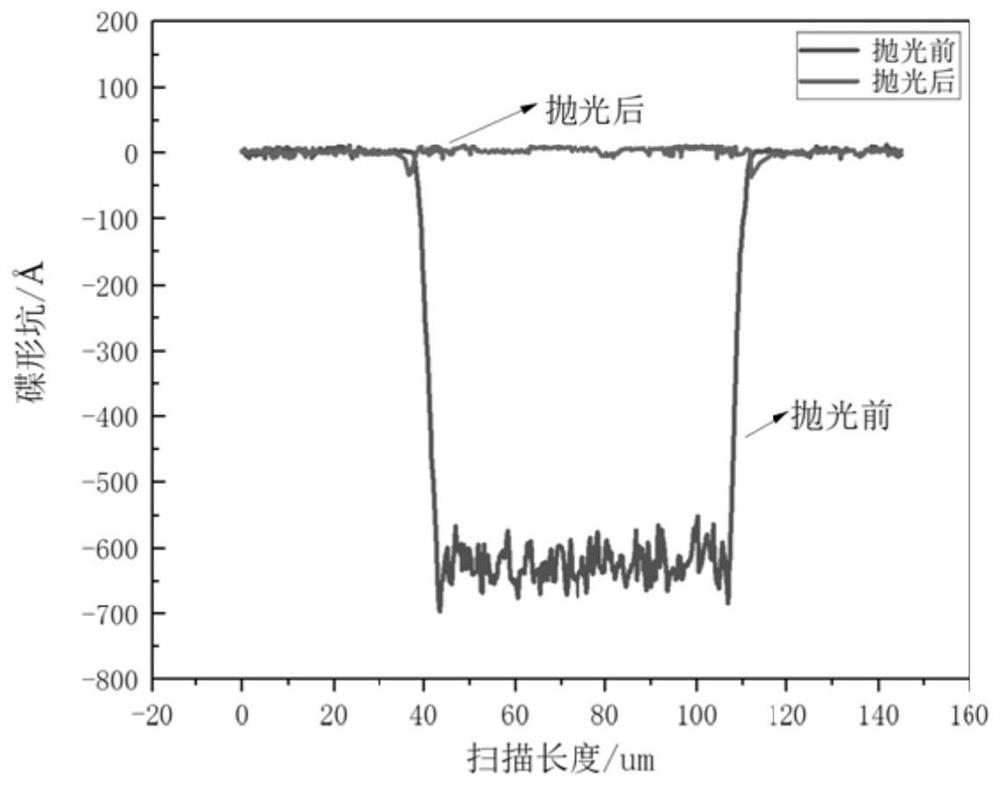

[0046] Experimental test: AMAT-LK CMP polishing machine produced by Applied Materials with the prepared polishing liquid S1; the working pressure i...

Embodiment 2

[0048] Take 250ml of silica sol with a mass fraction of 40% of the abrasive material, the particle size is 50nm-90nm, and the dispersion is between ±3%; citric acid chelated copper 10g; potassium citrate 5g; fatty alcohol polyoxyethylene ether 3g, lauryl Benzenesulfonic acid 1g. FA / O II chelating agent 0.5g, as a pH regulator, buffer and chelating agent. The specific preparation method is as follows: first mix FA / O type II chelating agent, citric acid chelated copper, potassium citrate, fatty alcohol polyoxyethylene ether, dodecylbenzenesulfonic acid and add appropriate amount of ionized water, then add silicon In the sol, stir evenly by means of step-by-step mixing, and finally make up to 1000g with deionized water, and continue stirring evenly to obtain polishing liquid S2.

[0049] Test monitoring: the pH of the polishing solution is 9.5, and the particle size is 80-120nm.

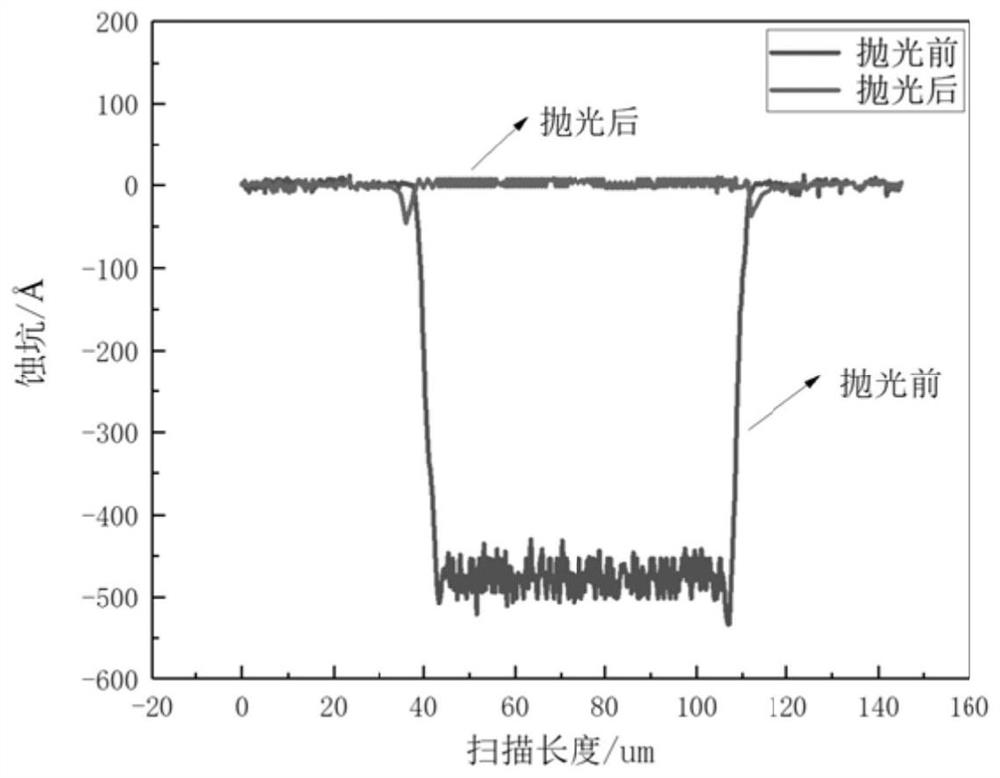

[0050] Experimental test: AMAT-LK CMP polishing machine produced by Applied Materials with the pre...

Embodiment 3

[0052] Take 250ml of silica sol with a mass fraction of 40% of the abrasive material, the particle size is 50nm-90nm, and the dispersion is between ±3%; citric acid chelated copper 10g; potassium citrate 10g; fatty alcohol polyoxyethylene ether 3g, lauryl Benzenesulfonic acid 1g. FA / O II chelating agent 0.5g, as a pH regulator, buffer and chelating agent. The specific preparation method is as follows: first mix FA / O type II chelating agent, citric acid chelated copper, potassium citrate, fatty alcohol polyoxyethylene ether, dodecylbenzenesulfonic acid and add appropriate amount of ionized water, then add silicon In the sol, stir evenly by means of step-by-step mixing, and finally make up to 1000g with deionized water, and continue to stir evenly to obtain polishing liquid S3.

[0053] Test monitoring: the pH of the polishing solution is 9.5, and the particle size is 80-120nm.

[0054] Experimental test: AMAT-LK CMP polishing machine produced by Applied Materials with the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com