Carbon/titanium dioxide coated tin oxide nano particle/carbon assembled mesoporous sphere material as well as preparation and application thereof

A nanoparticle, titanium dioxide technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, tin oxide, etc., can solve the problems of weakening the nanometer effect, unable to suppress the volume change of SnO2 well, and unable to significantly improve the cycle stability of SnO2, etc. Achieve stable cycle performance, improve electrochemical activity, and high specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

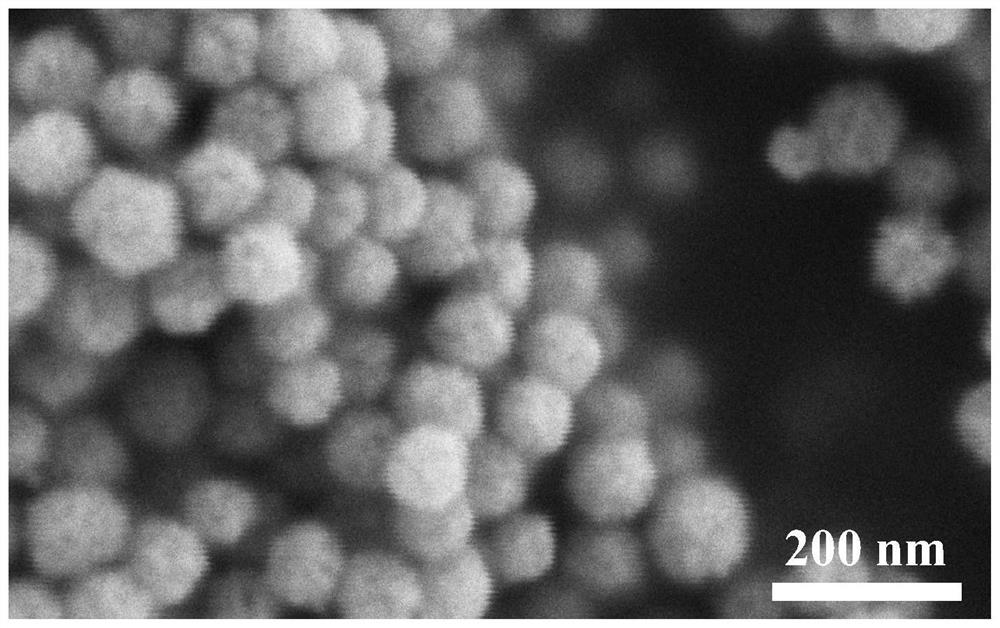

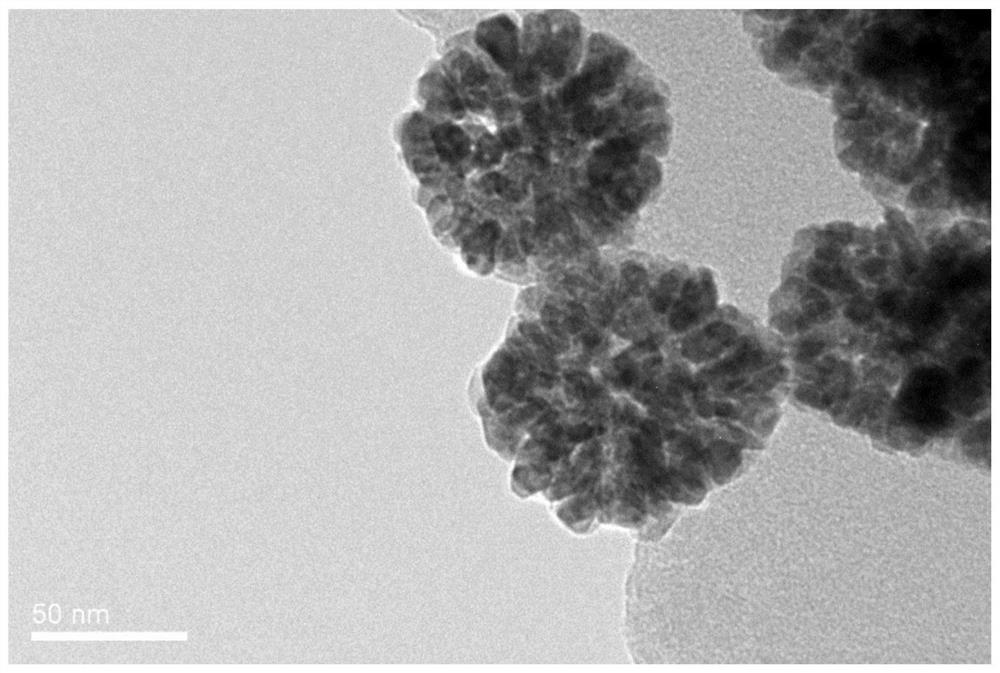

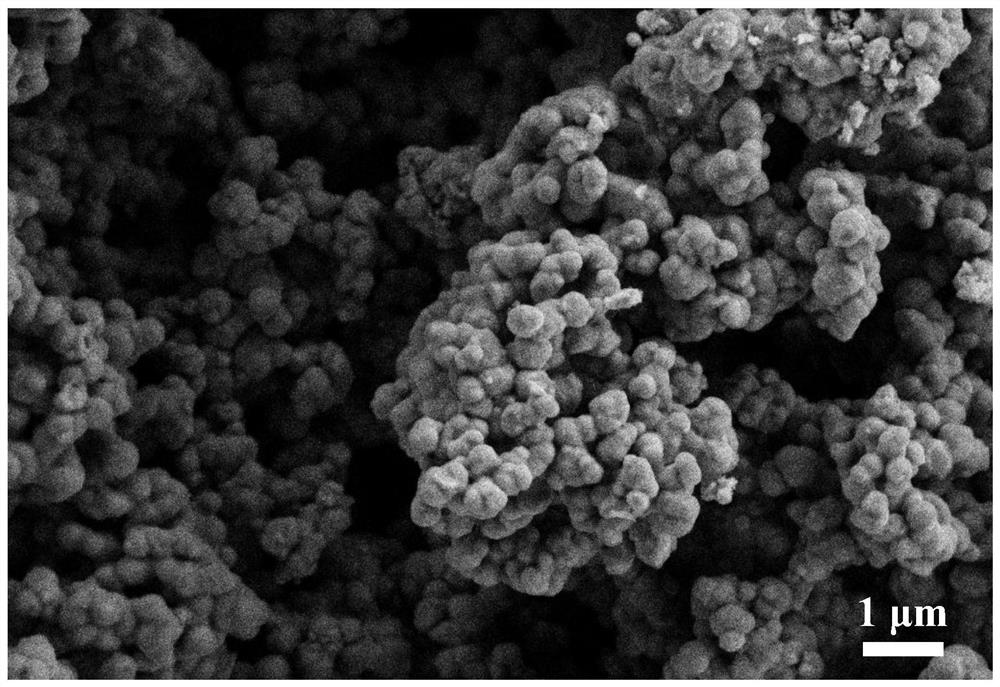

[0034] (1) Add 5 mL of diethylenetriamine to 60 mL of deionized water, and stir for 10 minutes to form a uniform oil-water mixed solution; add 110 mg of sodium stannate trihydrate, 400 mg of thiourea, and 50 mg of D-glucose anhydrous to the above solution in sequence, Stir for 1h. Transfer the above solution to a 100mL hydrothermal reaction kettle, seal it, heat it to 200°C for hydrothermal reaction for 24 hours, cool to room temperature, centrifuge the product, wash it with deionized water and absolute ethanol three times, and dry it at 60°C to obtain SnO 2 Nanoparticle / carbon assembled mesoporous spheres;

[0035] (2) 25mg SnO obtained in step (1) 2 Disperse nanoparticles / carbon-assembled mesoporous spheres in 50 mL of absolute ethanol, sonicate for 30 minutes, add 0.2 mL of isopropyl titanate, stir for 15 minutes, heat up to 60 ° C, slowly add 2 mL of deionized water, continue stirring for 90 minutes, and centrifuge to separate the product , washed three times with absol...

Embodiment 2

[0043] (1) Add 5 mL of diethylenetriamine to 60 mL of deionized water, and stir for 10 minutes to form a uniform oil-water mixed solution; add 110 mg of sodium stannate trihydrate, 400 mg of thiourea, and 50 mg of D-glucose anhydrous to the above solution in sequence, Stir for 1h. Transfer the above solution to a 100ml hydrothermal reaction kettle, seal it, heat it to 200°C for hydrothermal reaction for 24 hours, cool to room temperature, centrifuge the product, wash it with deionized water and absolute ethanol three times, and dry it at 60°C to obtain SnO 2 Nanoparticle / carbon assembled mesoporous spheres;

[0044] (2) 25mg SnO obtained in step (1) 2 Disperse nanoparticles / carbon-assembled mesoporous spheres in 50 mL of absolute ethanol, sonicate for 30 minutes, add 0.3 mL of isopropyl titanate, stir for 15 minutes, raise the temperature to 60 ° C, slowly add 3 mL of deionized water, continue stirring for 90 minutes, and centrifuge to separate the product. Wash 3 times wit...

Embodiment 3

[0049] (1) Add 5 mL of diethylenetriamine to 60 mL of deionized water, and stir for 10 minutes to form a uniform oil-water mixed solution; add 110 mg of sodium stannate trihydrate, 400 mg of thiourea, and 50 mg of D-glucose anhydrous to the above solution in sequence, Stir for 1h. Transfer the above solution to a 100ml hydrothermal reaction kettle, seal it, heat it to 200°C for hydrothermal reaction for 24 hours, cool to room temperature, centrifuge the product, wash it with deionized water and absolute ethanol three times, and dry it at 60°C to obtain SnO 2 Nanoparticle / carbon assembled mesoporous spheres;

[0050] (2) 25mg SnO obtained in step (1) 2 Disperse nanoparticles / carbon-assembled mesoporous spheres in 50mL absolute ethanol, ultrasonicate for 30min, add 0.2mL isopropyl titanate, stir for 15min, heat up to 60°C, slowly add 2mL deionized water, continue stirring for 90min, and centrifuge to separate the product. Wash 3 times with absolute ethanol and dry at 60°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com