Preparation method and application of NiO hollow nanospheres

A nanosphere and hollow technology, applied in nanotechnology, instruments, measuring devices, etc., can solve the problems of cumbersome steps, too many uncontrollable factors in the middle, and complexity, and achieve the effect of increasing specific surface area, low cost, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] At room temperature, 0.3 g of pectin was dissolved in 100 mL of water and vigorously stirred for 10 h, then 0.3 wt % pectin solution was added dropwise into 1 wt % nickel acetate solution while stirring continuously.

[0041]When nickel ions meet the pectin microspheres, they are immediately adsorbed to the surface of the pectin spheres, forming gel microspheres composed of adsorbed nickel ions. These gel microspheres were centrifuged and washed with water to remove excess salt, then freeze-dried in a freeze dryer for 36 hours.

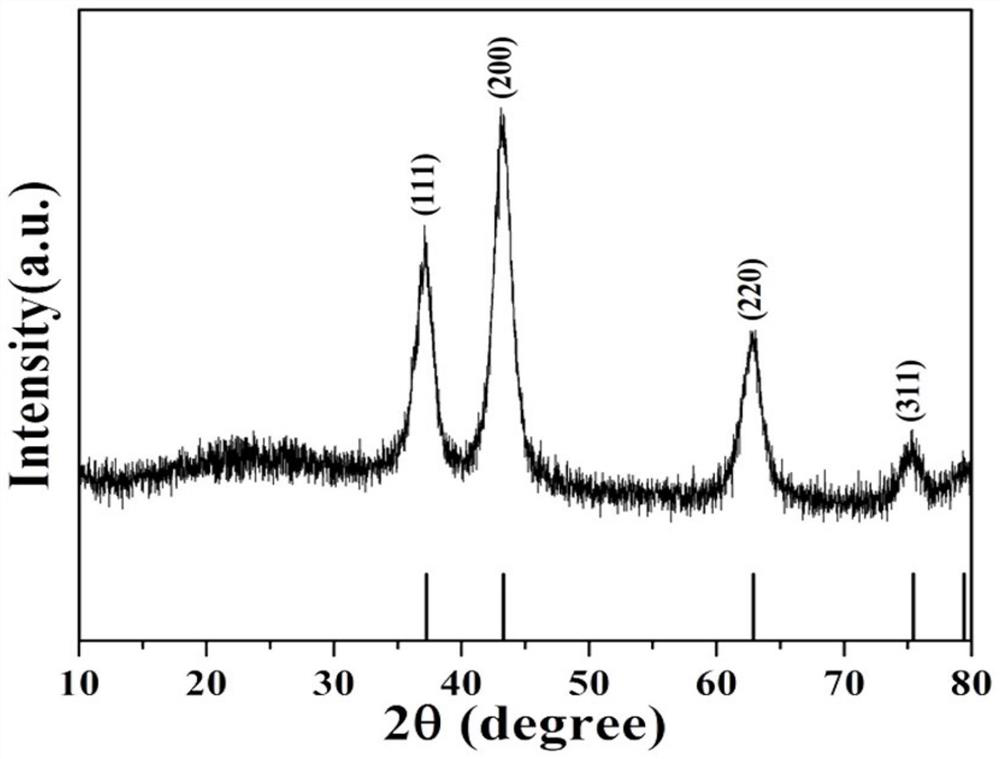

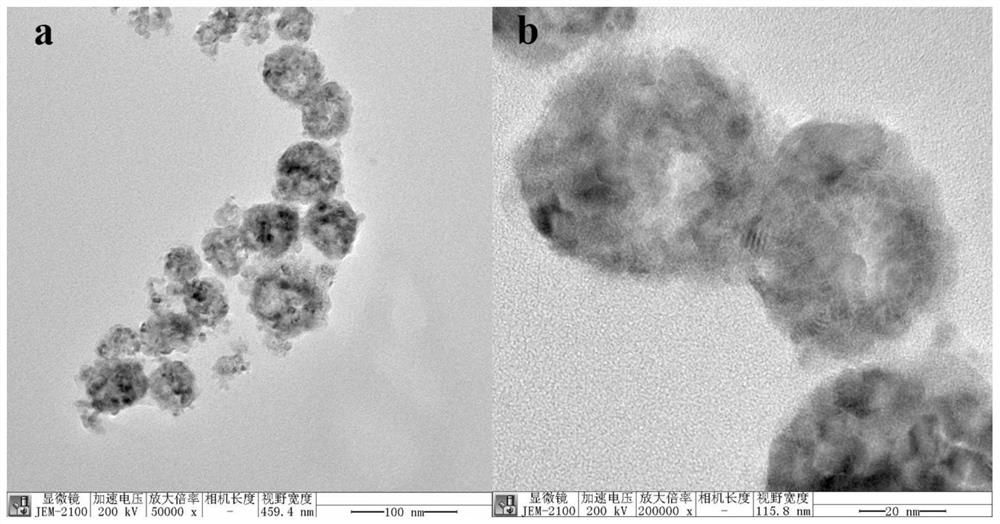

[0042] Dry the sample in N 2 Carbonization at 600°C for 2h under atmosphere, and finally firing in a fiber furnace at 400°C for 4h to obtain NiO hollow nanospheres. The hollow nanosphere is a nanosphere with a multi-level structure, and the nanosphere is constructed of nanoparticles. The diameter of the nanosphere is about 40-60nm, see Figure 1~2 .

[0043] figure 1 It is the XRD pattern of the sample powder after sintering at 400°C for 4 ...

Embodiment 2

[0045] S1: Preparation of nickel ion gel microspheres: The relative molecular weight of pectin is about 25,000. Under room temperature, dissolve pectin in water and stir vigorously for 5 hours to prepare it into a 0.1wt% pectin solution, and add it drop by drop Adding 5wt% nickel acetate solution, stirring continuously at the same time, after the dropwise addition, the solution is centrifuged, washed with water to remove excess salt, and freeze-dried;

[0046] S2: Preparation of NiO hollow nanospheres: nickel ion gel microspheres in N 2 Carbonization under the atmosphere, the carbonization temperature is 550°C, and the carbonization time is 4h; finally, it is fired in a fiber furnace, the firing temperature is 450°C, and the firing time is 3h.

Embodiment 3

[0048] S1: Preparation of nickel ion gel microspheres: The relative molecular weight of pectin is about 30,000. Under room temperature, dissolve pectin in water and stir vigorously for 10 hours to prepare a 1wt% pectin solution, and add it dropwise 1wt% nickel acetate solution, while constantly stirring, after the dropwise addition, the solution was centrifuged, washed with water to remove excess salt, and freeze-dried;

[0049] S2: Preparation of NiO hollow nanospheres: nickel ion gel microspheres in N 2 Carbonization under the atmosphere, the carbonization temperature is 650℃, the carbonization time is 2h; finally it is roasted in the fiber furnace, the roasting temperature is 350℃, the roasting time is 5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com