Preparation and application method of self-vulcanization oil-soluble multi-metal composite catalyst

A composite catalyst, self-sulfided oil technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of convenient low-cost large-scale industrial production, excellent hydrogenation activity, rapid and stable dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

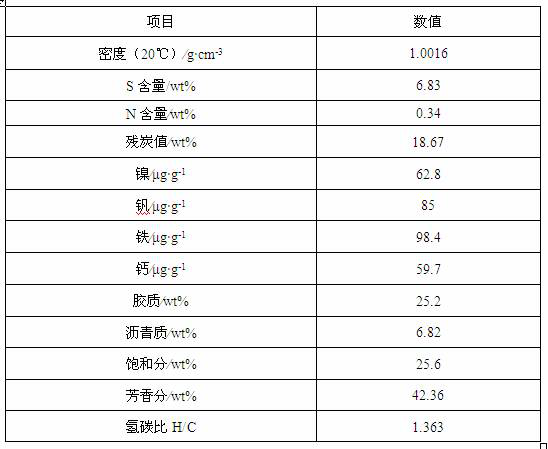

Examples

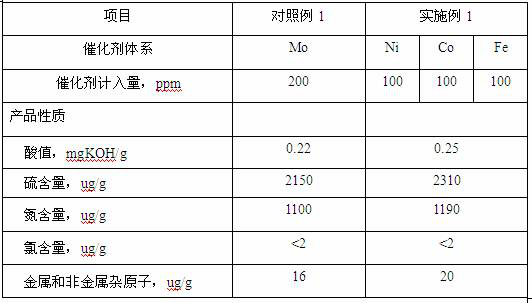

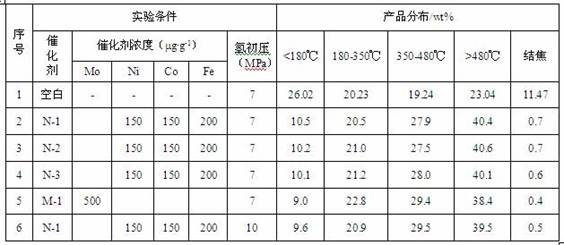

Embodiment 1

[0036] Weigh 74 g of n-butanol, heat up to 80 °C, add 40 g of sodium hydroxide, keep the reaction temperature at 80 °C, and react for 0.5 hours to obtain sodium butoxide; weigh 160 g of carbon disulfide, add sodium n-butoxide to carbon disulfide , keeping the reaction temperature at 30°C and stirring for 5 hours to obtain an alkyl-substituted thiocarbonate.

[0037]Weigh 50 g nickel nitrate hexahydrate, 50 g cobalt nitrate hexahydrate, 44 g ferric nitrate, add 300 mL distilled water, stir to dissolve, add alkyl-substituted thiocarbonate, reaction temperature 95 ° C, stir for 2 hours, The resulting reaction product was cooled to room temperature, and the water phase was removed by filtration to obtain a self-sulfurized oil-soluble multi-metal composite catalyst precursor, which was named N-1.

[0038] Under the condition of stirring, add the oil-soluble multi-metal composite catalyst precursor N-1 into the co-dispersant catalytic cracking diesel oil, catalytic cracking diesel o...

Embodiment 2

[0040] Take by weighing 88 g of n-amyl alcohol, heat up to 80 ° C, add 40 g of sodium hydroxide, keep the reaction temperature at 80 ° C, and react for 2 hours to obtain sodium n-pentoxide; weigh 160 g of carbon disulfide, add sodium n-pentoxide to In carbon disulfide, keep the reaction temperature at 30° C., and stir for 4 hours to obtain an alkyl-substituted thiocarbonate.

[0041] Weigh 40 g nickel chloride hexahydrate, 40 g cobalt chloride hexahydrate, 48 g ferric chloride hexahydrate, add 360 mL distilled water, stir to dissolve, add alkyl substituted thiocarbonate, reaction temperature 80 °C, Stirring and reacting for 2 hours, the resulting reaction product was cooled to room temperature, and the water phase was removed by filtration to obtain a self-sulfurized oil-soluble multi-metal composite catalyst precursor, which was named N-2.

[0042] Under stirring conditions, add the oil-soluble multi-metal composite catalyst precursor N-2 into the co-dispersant catalytic crac...

Embodiment 3

[0044] Take by weighing 108 g benzyl alcohol, be warming up to 90 DEG C, add 40 g sodium hydroxide, keep reaction temperature 90 DEG C, reaction time 2 hours, obtain sodium benzyl alkoxide; Take by weighing 200 g carbon disulfide, join sodium benzyl alkoxide in carbon disulfide, Keeping the reaction temperature at 30°C, the reaction was stirred for 5 hours to obtain aryl-substituted thiocarbonate.

[0045] Weigh 40 g of nickel chloride hexahydrate, 40 g of cobalt chloride hexahydrate, and 48 g of ferric chloride hexahydrate, add 360 mL of distilled water, stir to dissolve, add alkyl-substituted thiocarbonate, and the reaction temperature is 90 ° C. Stirring and reacting for 2 hours, the resulting reaction product was cooled to room temperature, and the water phase was removed by filtration to obtain a self-sulfurized oil-soluble multi-metal composite catalyst precursor, which was named N-3.

[0046] Under the condition of stirring, add the oil-soluble multi-metal composite cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com