Soil remediation agent prepared from crop straw and biochar

A soil remediation agent and crop straw technology, which is applied in the field of soil remediation, can solve the problems of the decline in the ability of biomass char to adsorb pollutants, the fertility effect is not obvious, and the nutrient function is single, so as to achieve reduction treatment and resource utilization. , non-toxic and side effects, good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

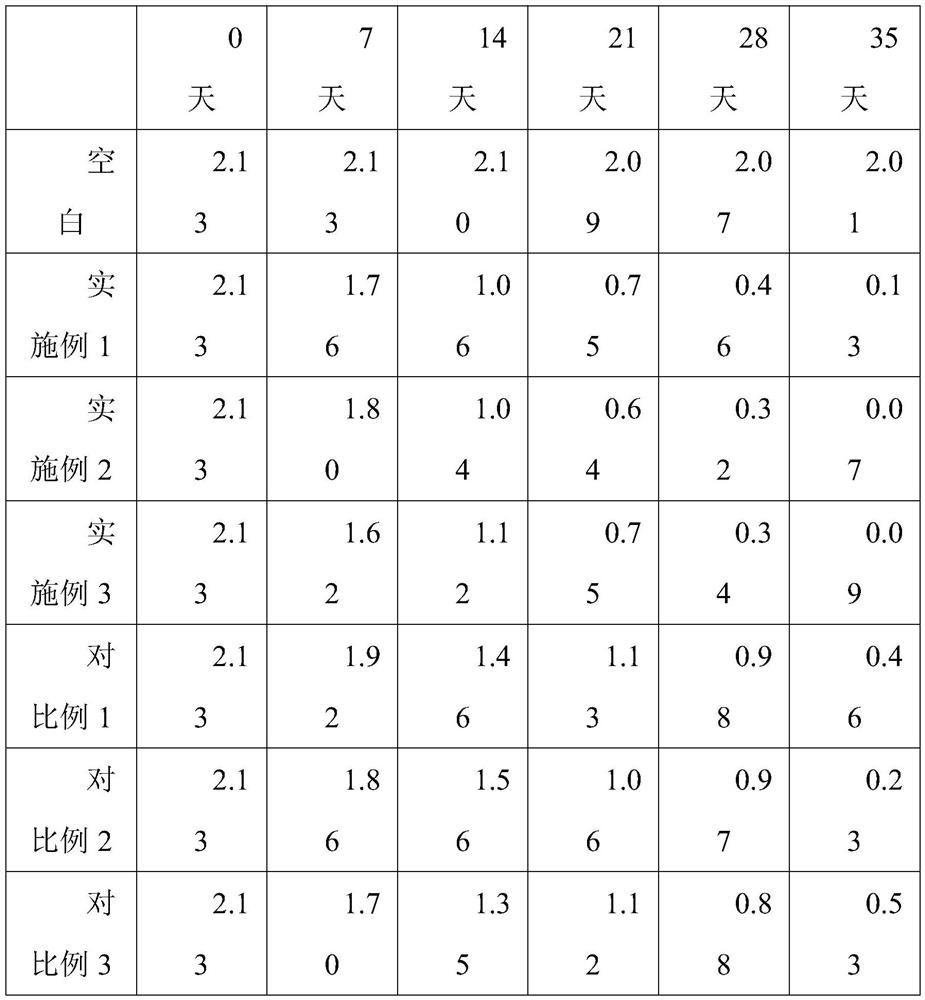

Examples

Embodiment 1

[0032] A soil remediation agent made from crop stalks and biochar, prepared by the following steps in parts by weight:

[0033] (1) Dry and pulverize the soybean stalks and carry out steam explosion treatment to prepare blasting straw powder; the straw pulverization treatment is pulverized through a 120 mesh sieve, and dried to a moisture content≤15wt%; the steam explosion treatment is: at a steam pressure of 3.5 Under the conditions of MPa and temperature 130°C, release the pressure after holding the pressure for 240s;

[0034] (2) Take 100 parts of straw powder in step (1), add 3 parts of FeCl3, 6 parts of titanate coupling agent, and 4 parts of zeolite, mix evenly, put into a pyrolysis activation device, and carry out under anaerobic conditions High-temperature pyrolysis reaction to generate biochar, the pyrolysis reaction temperature is 550°C, and the pyrolysis reaction time is 1.5h;

[0035] (3) Take 100 parts of straw powder in step (1), add 4 parts of sodium bentonite,...

Embodiment 2

[0039] A soil remediation agent made from crop stalks and biochar, prepared by the following steps in parts by weight:

[0040] (1) Dry and pulverize sorghum stalks and carry out steam explosion treatment to prepare blasting straw powder; the straw pulverization treatment is pulverized through a 10-mesh sieve, and dried to a moisture content≤15wt%; the steam explosion treatment is: at a steam pressure of 2MPa 1. Under the condition of temperature 110℃, release the pressure after holding the pressure for 200s;

[0041] (2) Take 100 parts of straw powder in step (1), add 2 parts of FeCl3, 4 parts of titanate coupling agent, and 2 parts of zeolite, mix evenly, put into a pyrolysis activation device, and carry out under anaerobic conditions High-temperature pyrolysis reaction to generate biochar, the pyrolysis reaction temperature is 500°C, and the pyrolysis reaction time is 1.5h;

[0042](3) Take 100 parts of straw powder in step (1), add 2 parts of sodium bentonite, 5 parts of ...

Embodiment 3

[0046] A soil remediation agent made from crop stalks and biochar, prepared by the following steps in parts by weight:

[0047] (1) Dry and pulverize the sugarcane stalks and carry out steam explosion treatment to prepare blasting straw powder; the straw pulverization treatment is pulverized through a 20-mesh sieve, and dried to a moisture content≤15wt%; the steam explosion treatment is: at a steam pressure of 2.2 Under the conditions of MPa and temperature 120°C, release the pressure after holding the pressure for 240s;

[0048] (2) Take 100 parts of straw powder in step (1), add 3 parts of FeCl3, 6 parts of titanate coupling agent, and 2 parts of zeolite, mix evenly, put into a pyrolysis activation device, and carry out under anaerobic conditions High-temperature pyrolysis reaction to generate biochar, the pyrolysis reaction temperature is 480°C, and the pyrolysis reaction time is 1.5h;

[0049] (3) Take 100 parts of straw powder in step (1), add 4 parts of sodium bentonite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com