Method for repairing chlorinated hydrocarbon-contaminated site through in-situ chemical oxidation

A technology for in-situ chemical oxidation and chlorination of hydrocarbons, applied in chemical instruments and methods, restoration of polluted soil, organic fertilizers, etc. To achieve the effect of improving oxidation efficiency, improving soil structure, and enhancing water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

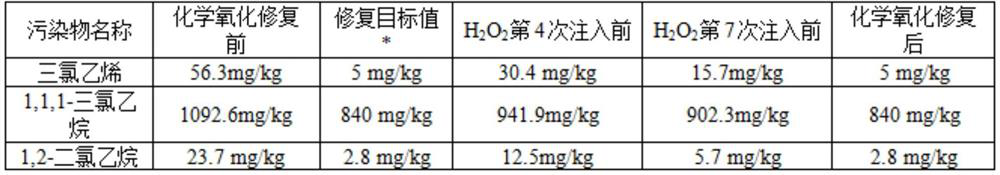

Examples

Embodiment 1

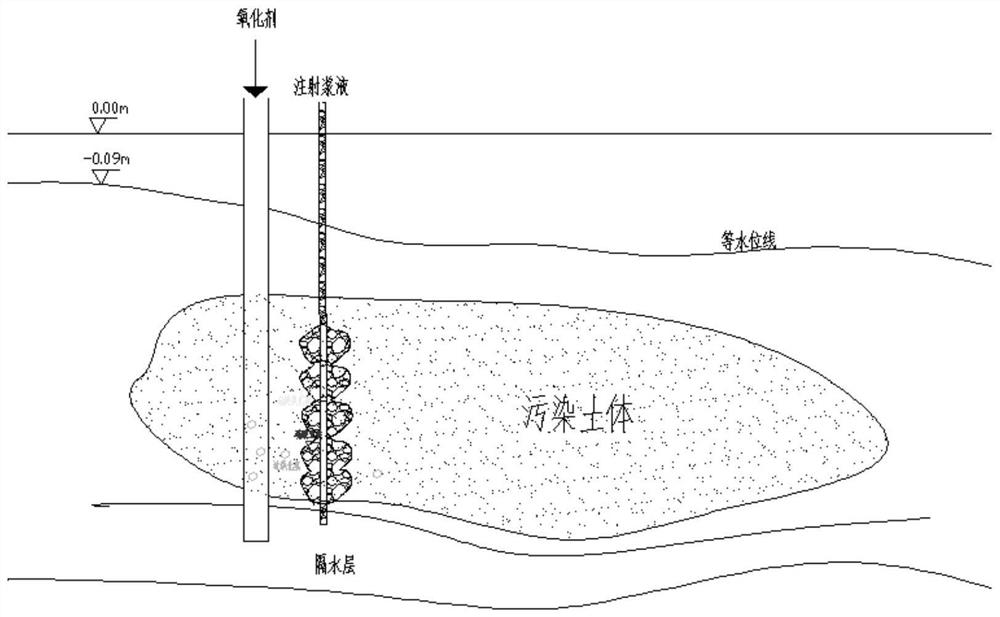

[0034] A method for repairing chlorinated hydrocarbon contaminated sites by in-situ chemical oxidation, comprising the following steps:

[0035] 1. According to the situation of the contaminated site, the solid oxidant points and liquid oxidant injection wells are arranged at equal intervals according to the grid method.

[0036] 2. The molar ratio of the total dosage of solid oxidant to the concentration of chlorinated hydrocarbon site pollutants is 8:1, and the mass ratio of calcium peroxide to persulfate oxidant is 1:2.

[0037] 3. Before the solid oxidant is sprayed into the ground, the fine sand is injected into the ground with a powder spraying pile driver, and the injection volume is 80kg / m for each pile 3 .

[0038] 4. The amount of catalyst ferrous sulfate injected into the ground together with the solid oxidant is: the molar ratio of the dosage of calcium peroxide to ferrous sulfate is 20:1, and the molar ratio of the dosage of persulfate to ferrous sulfate It is 1...

Embodiment 2

[0047] A method for repairing chlorinated hydrocarbon contaminated sites by in-situ chemical oxidation, comprising the following steps:

[0048] 1. According to the situation of the polluted site, arrange the solid oxidant points and liquid oxidant injection wells at equal intervals according to the plum blossom method.

[0049]2. The molar ratio of the total dosage of solid oxidant to the concentration of chlorinated hydrocarbon site pollutants is 10:1, and the mass ratio of calcium peroxide to persulfate oxidant is 1:4.

[0050] 3. Before the solid oxidant is sprayed into the ground, the fine sand is injected into the ground with a powder spraying pile driver, and the injection volume is 160kg / m for each pile 3 .

[0051] 4. The dosage of the catalyst ferrous sulfate injected into the ground together with the solid oxidant is: the molar ratio of the dosage of calcium peroxide to ferrous sulfate is 10:1, and the molar ratio of the dosage of persulfate to ferrous sulfate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com