Solid electrolyte and preparation method and application thereof

A solid electrolyte, electrolyte technology, applied in the direction of solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., can solve the problems of low electrical conductivity and low mechanical strength of electrolyte, achieve high mechanical strength, improve interface contact, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

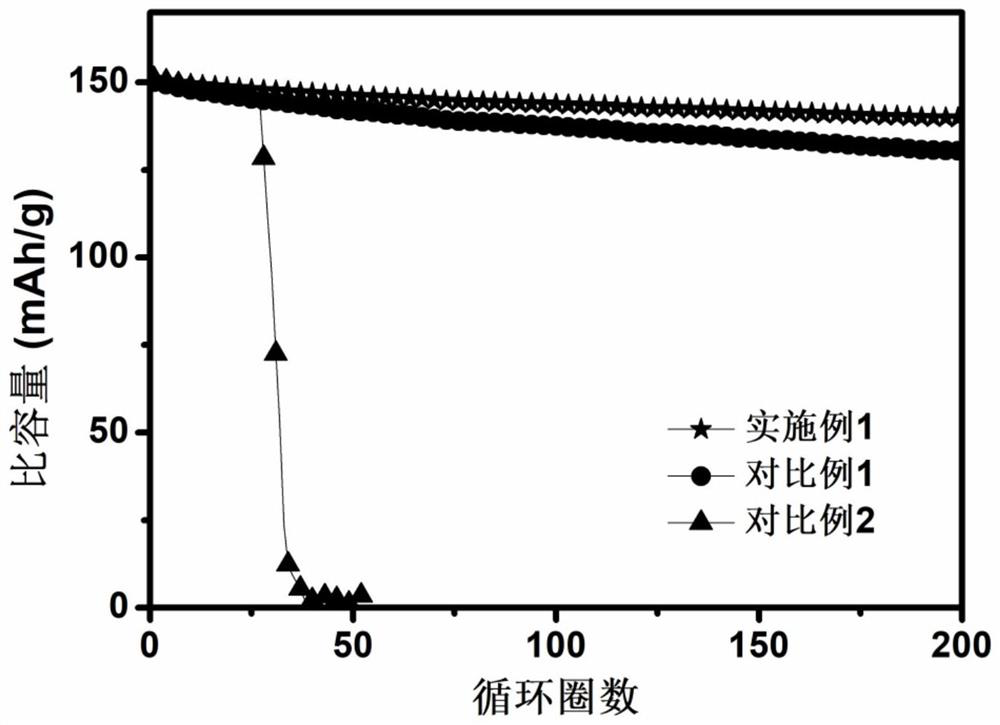

Embodiment 1

[0051] (1) Mix cobalt nitrate hexahydrate, trimesic acid and methanol with a molar ratio of 1:2:520 evenly, immerse the glass fiber in the above solution, shake it on a shaker for 24 hours, and take it out. The shaking temperature is 30°C , a new type of three-dimensional framework was obtained after vacuum drying at 80 °C.

[0052] (2) Weigh lithium bis(trifluoromethylsulfonyl)imide, polyethylene oxide and acetonitrile in a molar ratio of 1:16:0.43, and stir for 24 hours to obtain a uniform sol.

[0053] (3) The prepared new three-dimensional framework was placed on a polytetrafluoroethylene plate, and the above-mentioned sol was scraped on the front and back sides of the new three-dimensional framework. The vinyl plate was peeled off to obtain a solid electrolyte.

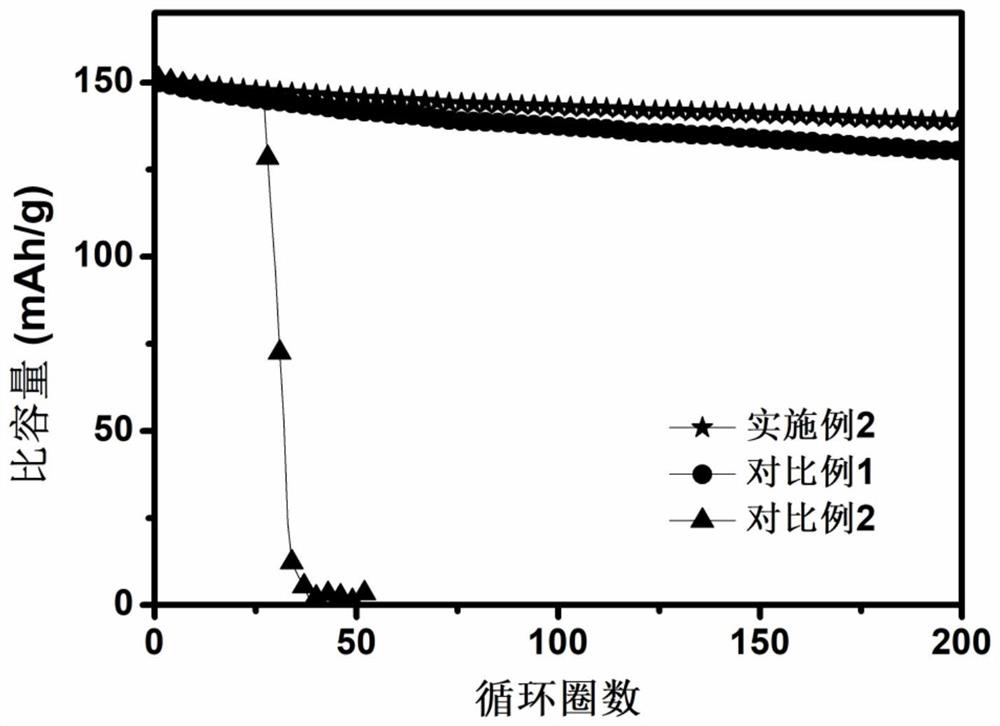

Embodiment 2

[0055] The solid electrolyte was produced in the same manner as in Example 1, except that in step (1), the metal salt was cobalt nitrate hexahydrate, the organic ligand was terephthalic acid, the organic solvent I was ethanol, and the molar ratio was 1 : 1.5:300, the shaking temperature is 30°C; in step (2), the lithium salt is lithium tetrafluoroborate, the polymer matrix is polyethylene oxide, the organic solvent II is acetonitrile, and the molar ratio is 1:16:0.43.

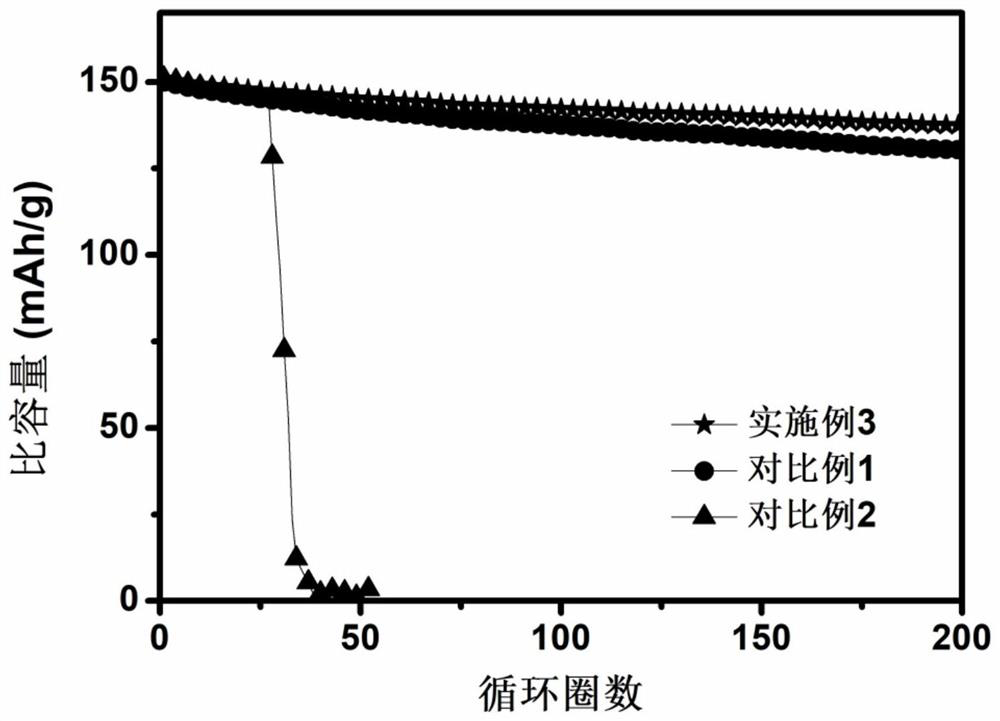

Embodiment 3

[0057] The solid electrolyte was produced in the same manner as in Example 1, except that in step (1), the metal salt was tetrabutyl titanate, the organic ligand was 2-amino-terephthalic acid, and the organic solvent I was N , N-dimethylformamide, the molar ratio is 1:1.5:390, and the shaking temperature is 60 °C; in step (2), the lithium salt is lithium trifluoromethanesulfonate, and the polymer matrix is polyvinylidene fluoride-hexa Fluoropropene, the organic solvent II is N-methylpyrrolidone, and the molar ratio is 1:13:0.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com