Porous vacuum chuck and preparation method thereof

A vacuum suction cup and porous adsorption technology, which is applied in the direction of ceramic products, final product manufacturing, and other household appliances, etc. It can solve the problems of difficult precise control of the structure and orientation of holes, increased material cost and time cost, and limited number of holes. , to achieve the effect of reducing material cost and management cost, uniform adsorption force and small flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

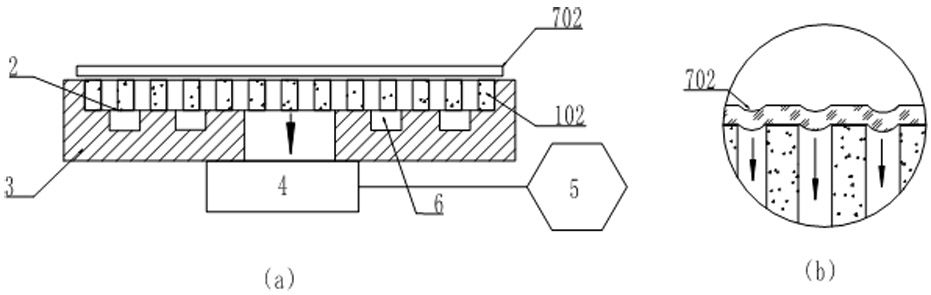

[0044] After heating the camphene solvent in a constant temperature water bath to 80°C, add 20vol% of alumina powder with an average particle size of 1 μm, 2.5wt% of polyacrylamide and 2.5wt% of gum arabic to the solvent, and after stirring evenly, Place in a ball mill preheated to 80° C., and ball mill at a speed of 200 r / min for 8 hours to prepare a ceramic slurry.

[0045] Set the cooling platform to -50°C, place a bottom plate 10 (made of copper) with a thickness of 1 mm and a circular frame 11 made of polytetrafluoroethylene with a thickness of 20 mm in sequence, and quickly pour the prepared ceramic slurry into the mold , after cooling for 8 hours, the slurry was completely frozen, the frame 11 was removed, the frozen disc-shaped body was removed, and placed in a ventilated environment at 20°C for sublimation and drying for 24 hours.

[0046] The dried disc-shaped blank is put into an atmospheric pressure sintering furnace and sintered at 1550° C. to obtain porous alumin...

Embodiment 2

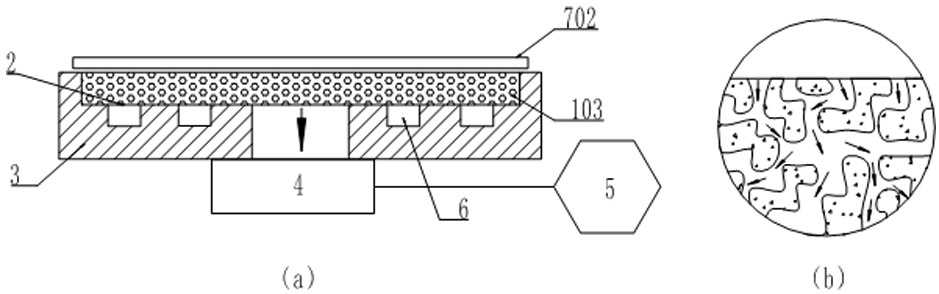

[0052] Heat the tert-butanol solvent in a constant temperature water bath to 50°C, add 60vol% of YSZ zirconia powder with an average particle size of 3μm, 2wt% of methylcellulose and 1wt% of polyvinyl alcohol into the solvent, and stir it evenly , placed in a ball mill preheated to 50°C, and ball milled at a speed of 800r / min for 4h to prepare a ceramic slurry.

[0053] Set the cooling platform to -80°C, place the aluminum mold bottom plate 10 with a thickness of 3mm and the polyurethane double-ring mold frame 11 with a thickness of 40mm in sequence, pour the prepared ceramic slurry into the ring mold quickly, and wait for cooling for 2 hours Finally, all the slurry is frozen, the frame 11 is removed, the frozen YSZ annular body is taken off, and placed in a ventilated environment at 10°C for sublimation and drying for 40 hours.

[0054] The dried YSZ annular body is put into an atmospheric sintering furnace and sintered at 1600°C to obtain porous zirconia ceramics. It also h...

Embodiment 3

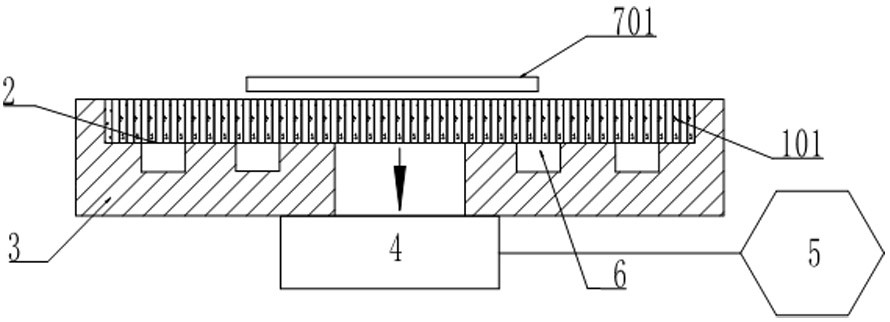

[0061] Mix tert-butanol and water at a concentration of 70wt%, heat it in a constant temperature water bath to 60°C, and then add 40vol% of silicon carbide powder with an average particle size of 25μm, 4wt% of tetramethylammonium hydroxide and 6wt% of polyethylene Alcohol, after being uniformly stirred, placed in a ball mill preheated to 60°C, and ball milled at a speed of 600r / min for 20h to prepare a ceramic slurry.

[0062] Set the cooling platform to -40°C, place a stainless steel mold bottom plate 10 with a thickness of 5mm and a nylon square mold frame 11 with a thickness of 40mm in turn, pour the prepared ceramic slurry into the mold quickly, and wait for cooling for 8 hours Finally, the slurry is completely frozen, the frame 11 is removed, and the frozen square plate-shaped silicon carbide green body is removed, and placed in a ventilated environment at 5°C for sublimation drying for 48 hours.

[0063] The dried square plate-shaped silicon carbide green body is put int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com