Multifunctional biomass composite building material and preparation method

A composite building material and biomass technology, which is applied in the field of multifunctional biomass composite building materials and its preparation, can solve the problem of weak durability stress reduction of reinforced glass fiber mesh cloth, inability to bear the load stress of public buildings, and the cost and price of epoxy resin Problems such as staying high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

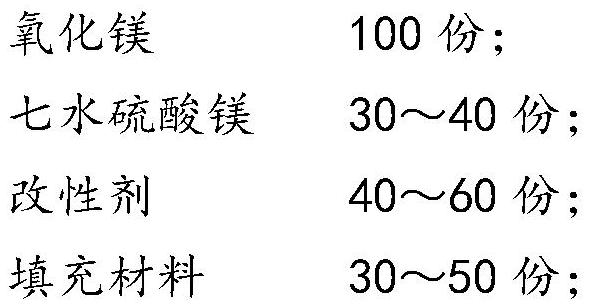

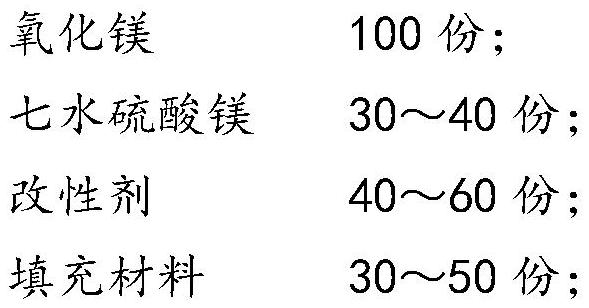

[0034] A multifunctional biomass composite building material is made of the following raw materials in parts by weight:

[0035]

[0036] Wherein, the weight of active magnesium oxide in the magnesium oxide accounts for 50% to 75% of the total weight of magnesium oxide, and the modifier is composed of phosphoric acid, stone alkali, organic silicon compound, methyl / butyl acrylate and mica powder, And the weight ratio among them is 0.05˜1:1˜5:1˜5:1˜5:2˜12.

[0037] It should be noted that in the process of preparing the above-mentioned building boards, water is needed, and the amount of water is not required too much. It only needs to make the solid substances fully moisten and swell and stir to form a paddle. .

[0038] In the process of implementing the present invention, the above-mentioned activated magnesium oxide refers to the active ingredient magnesium oxide that can directly participate in the mutual reaction of materials. The overall reaction is an exothermic react...

Embodiment 2

[0056] A preparation method for preparing the above-mentioned multifunctional biomass composite building material, comprising the steps of:

[0057] 1) Prepare materials according to the above parts by weight, and pulverize the solid raw materials into micropowder particles above 100 mesh;

[0058] 2) Place the magnesium sulfate heptahydrate and the modifier in the slurry bin of the mixer, add water and stir to dissolve, then add magnesium oxide and filler material to the slurry bin and then fully stir to form a slurry;

[0059] 3) pouring the slurry in step 2 into the wallboard formwork, and leveling the slurry in the wallboard formwork, and then placing a plurality of raw biomass bamboos above the slurry;

[0060] 4) Obtain foam through an air compressor, inject the foam into the slurry bin and stir to obtain the adsorption raw material;

[0061] 5) pouring the adsorption raw material obtained in step 4 into the wallboard formwork, and covering the non-woven grid cloth or m...

Embodiment 3

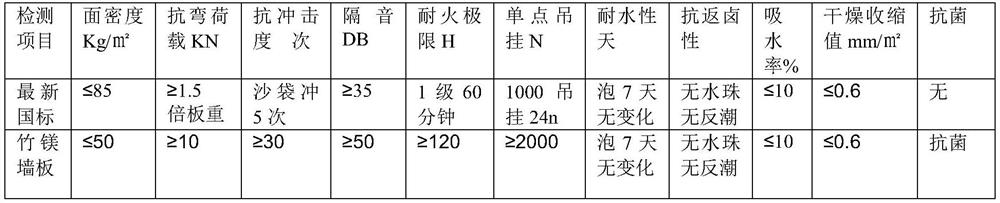

[0070] A biomass wallboard, which is prepared from the above-mentioned multifunctional biomass composite building material according to the above-mentioned preparation method, and a core material is arranged inside the wallboard, the main component in the core material is an air-entraining agent, and the surface of the wallboard is also It has a decorative layer, which is composed of different colors of different organic materials, such as white, gray, yellow, red, blue, green, etc. in mica powder, and rice husk, wheat straw powder, mahogany powder, etc. in fiber biomass materials. Oak powder and bamboo bran have different colors, and organic matter extraction pigments such as iron dioxide red, iron green, iron yellow, etc. can also be added to color. The mixture of these different color materials can form a beautiful wall panel with bright spots on the surface. It is the decorative layer.

[0071] Preferably, there are at least two core materials, and the core material can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com