Liquid crystal polymer substrate and processing method thereof

A technology of liquid crystal polymer and processing method, applied in nonlinear optics, instruments, optics, etc., can solve the problems of poor high-frequency characteristics of liquid crystal polymer film, poor heat resistance of liquid crystal polymer film, and low bonding strength, etc. Excellent peel strength, high peel strength, high bond strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

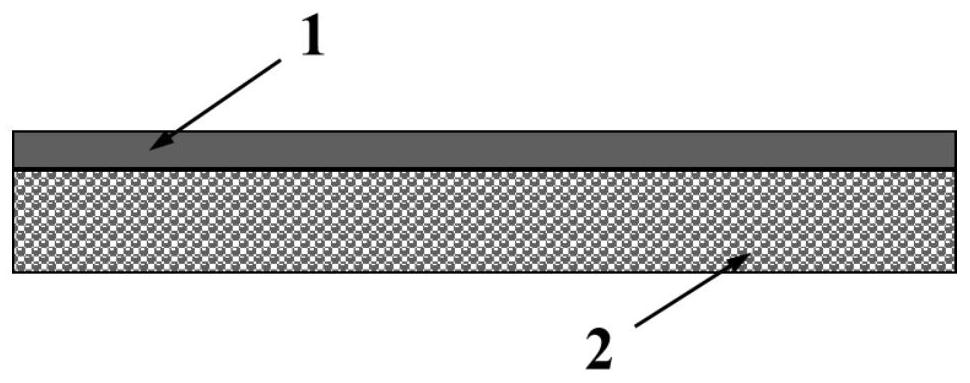

[0074] Melting point is T m1 The liquid crystal polymer is a liquid crystal copolyester of p-hydroxybenzoic acid, 4,4'-dihydroxybiphenyl and terephthalic acid with a melting point of 320 ° C, and a melting point of T m2 For the liquid crystal polymer, the liquid crystal copolyester of p-hydroxybenzoic acid and 6-hydroxy-2-naphthoic acid with a melting point of 280°C is selected, and the liquid crystal polymer material is dried and pretreated in a vacuum drying oven at a drying temperature of 150°C. The drying time is 5 hours, and the water content of the resin after drying is less than 300ppm. T according to melting point m2 The mass percentage of the liquid crystal polymer resin accounting for the total resin amount of the liquid crystal polymer film is 1.0%. The two liquid crystal polymers are evenly mixed, and then blended and granulated by a co-rotating twin-screw extruder, and blended to form The granulated liquid crystal polymer material is dried in a vacuum drying ove...

Embodiment 2

[0077] The difference from Example 1 is that the melting point is T m2 The liquid crystal polymer resin accounts for 5.0% by mass of the total resin amount of the liquid crystal polymer film.

Embodiment 3

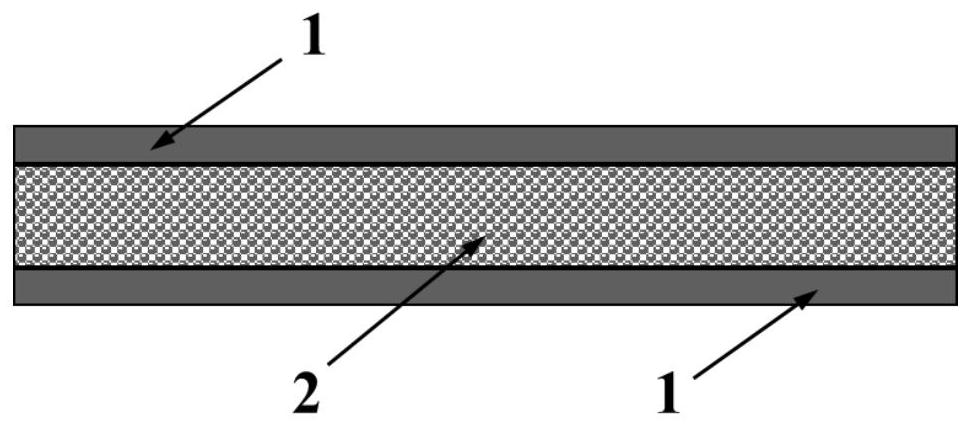

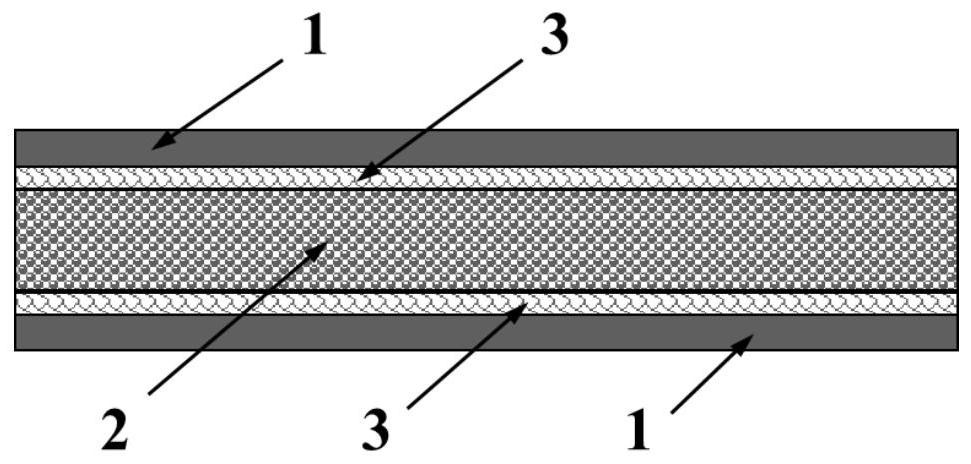

[0079] The difference from Example 2 is that both sides of the composite liquid crystal polymer film 2 are covered with copper foil, that is, they are stacked in the order of copper foil / composite liquid crystal polymer film 2 / copper foil, and then hot-pressed to obtain Liquid crystal polymer substrate (such as figure 2 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com