Fe/Fe3C embedded N-doped carbon composite material, preparation method thereof and application thereof in microbial fuel cells

A technology of carbon composite materials and fuel cells, which is applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of poor durability, performance attenuation, and high cost, so as to improve performance, high voltage and output power, and overcome costs high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of Fe framework, specific steps are as follows:

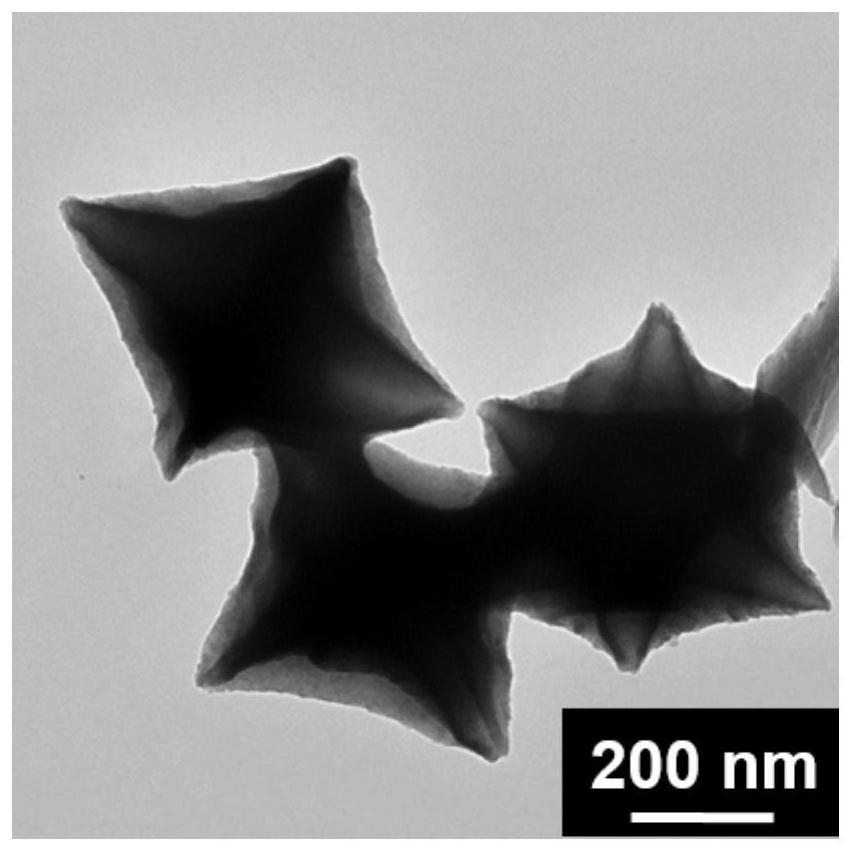

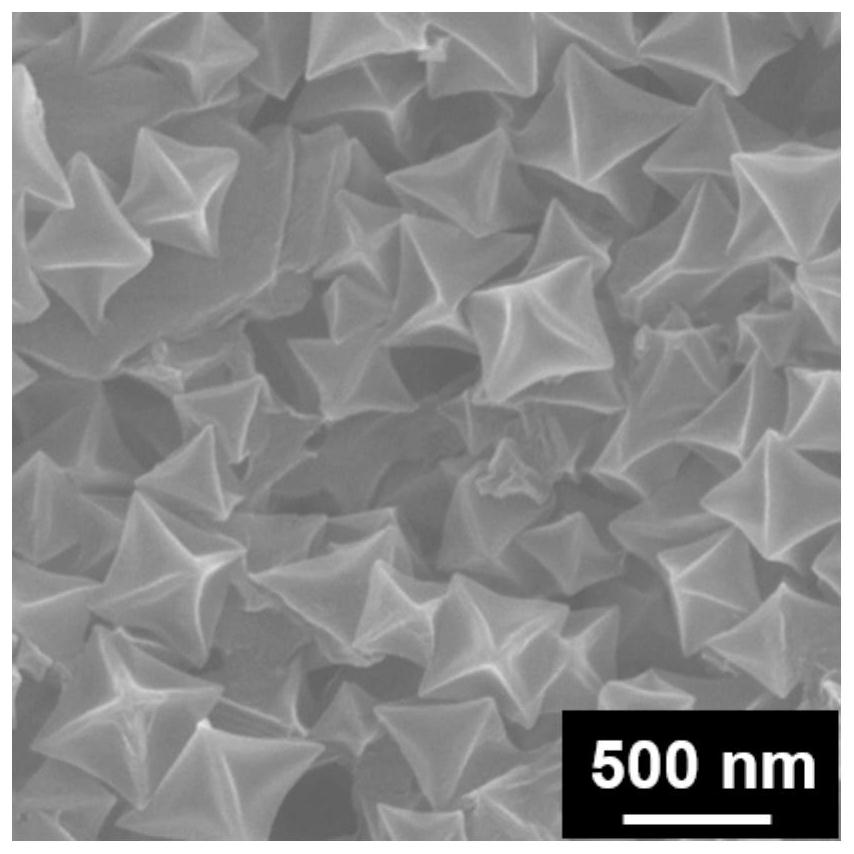

[0035] 0.675 g FeCl 3 ·6H 2 O and 0.207 g of terephthalic acid were dispersed in 15 mL of DMF, followed by routine sonication for 20 min. The obtained solution was poured into a 50 mL reaction kettle, moved to an oven, and heated to 110 °C for 20 h. Finally, the product was centrifuged and washed with DMF and hot ethanol, and dried under vacuum at 60 °C to obtain the Fe framework. attached figure 1 TEM image of the Fe frame, attached figure 2is the SEM image of the Fe frame. It can be seen from the figure that the as-prepared Fe framework presents a concave octahedral morphology with a uniform size of about 500 nm and a smooth surface.

Embodiment 2

[0037] The preparation of Fe / GO / CS composites, the specific steps are as follows:

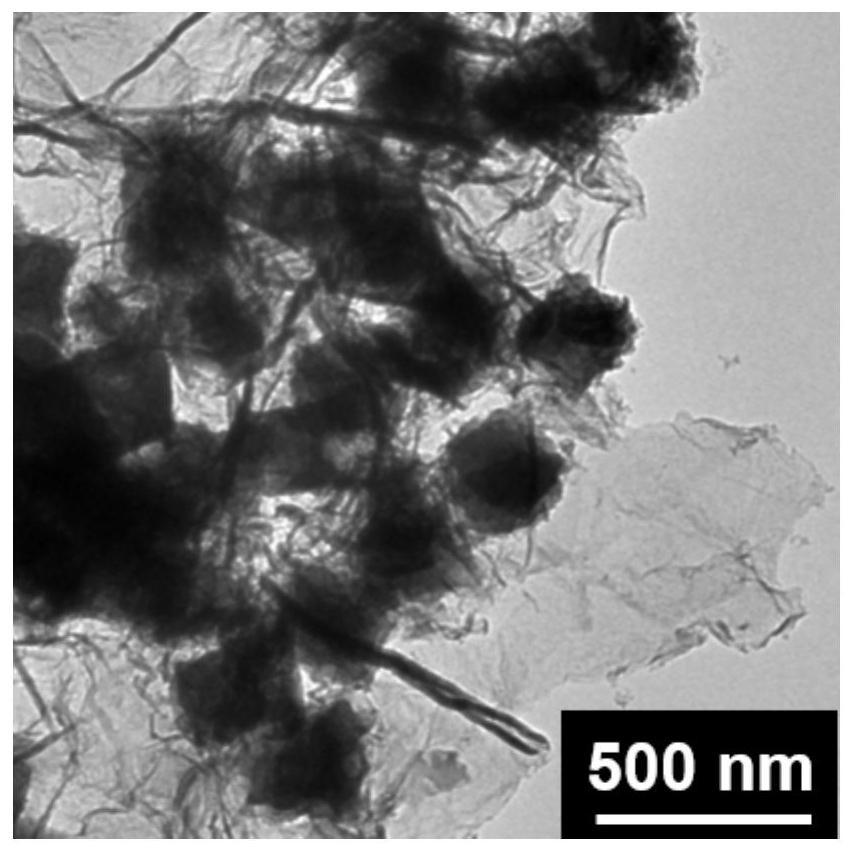

[0038] using the in situ growth method. Disperse 0.03 g of carbon-based material graphene oxide and 0.1 g of nitrogen source chitosan in 15 mL of DMF and routinely sonicate for 1 h; then add 0.675 g of FeCl 3 ·6H 2 O and 0.207 g terephthalic acid, and sonicated for 20 min; the resulting solution was then transferred to a reaction kettle and heated to 110 °C for 20 h; finally, the product was centrifuged and washed with DMF and hot ethanol, and Dry at 60°C to obtain Fe / GO / CS composite. attached image 3 is the TEM image of the Fe / GO / CS composite, with Figure 4 It is the SEM image of the Fe / GO / CS composite, the surface becomes relatively rough after the composite is formed.

Embodiment 3

[0040] The difference between this embodiment and the above-mentioned Example 2 is that: the carbon-based material is carbon nanotubes, and the others are the same as in Example 2 to obtain a Fe / CN / CS composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com