High-temperature-resistant hot-melt pressure-sensitive adhesive as well as preparation method and application thereof

A technology of hot-melt pressure-sensitive adhesives and formulations, applied in the direction of pressure-sensitive films/sheets, adhesives, heat-activated films/sheets, etc., which can solve problems such as poor low temperature resistance, coil loss, and no protective layer, etc., to achieve excellent High temperature stickiness, excellent high and low temperature resistance, high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

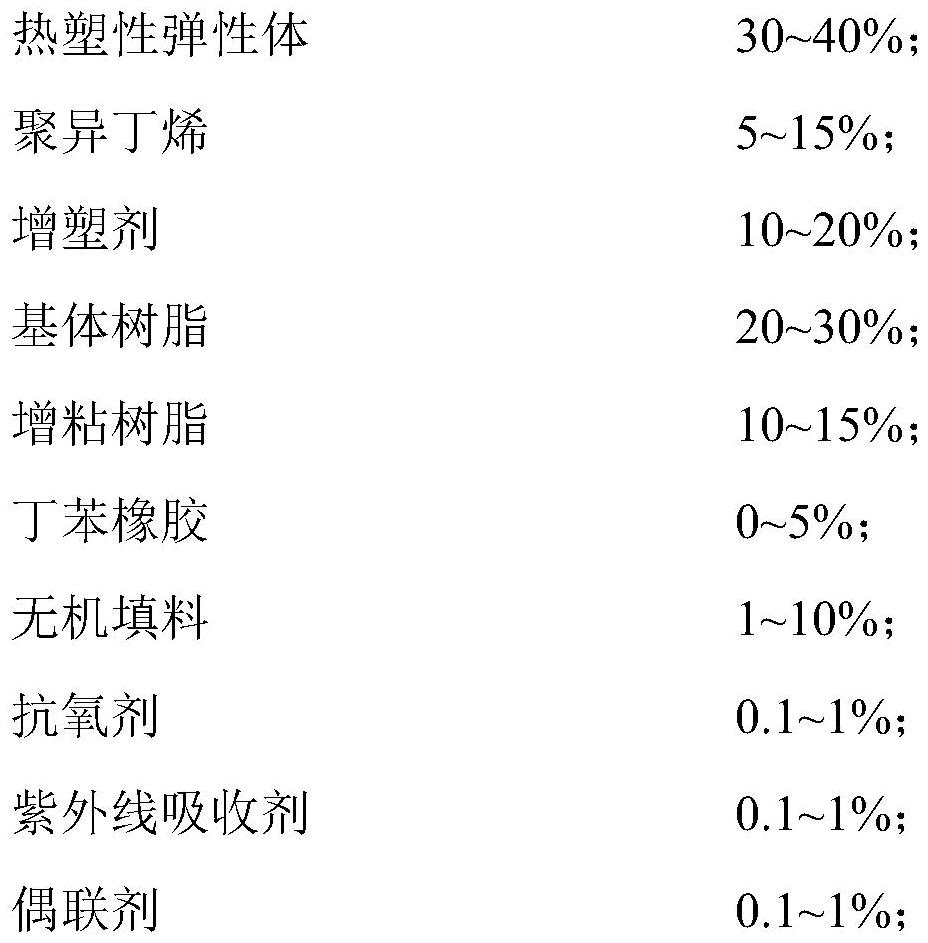

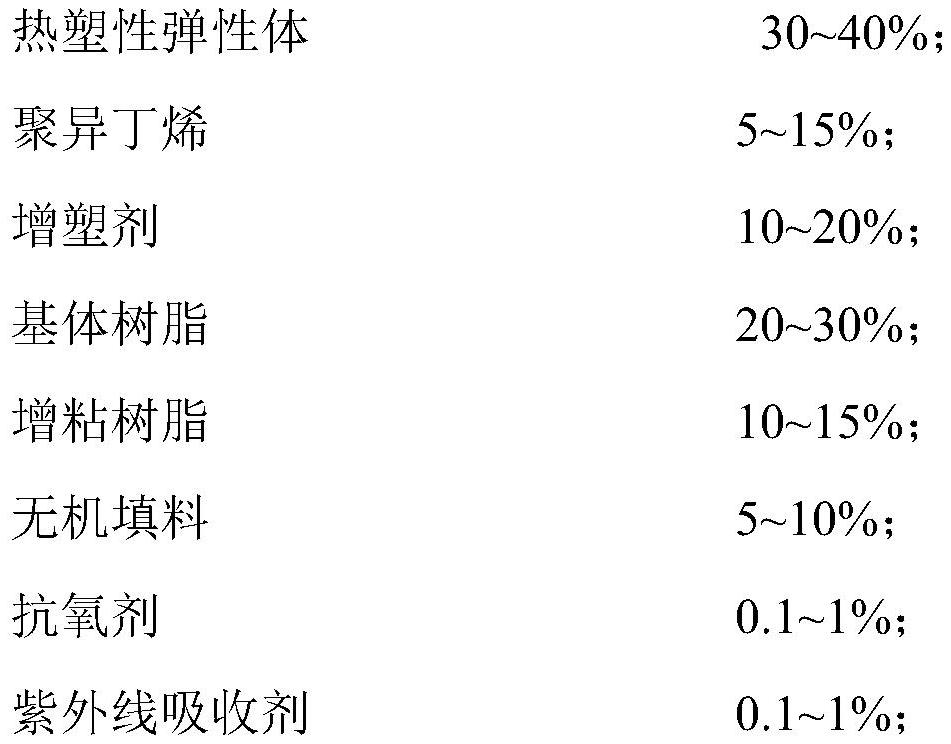

[0032] The high-temperature-resistant non-bitumen-based hot-melt pressure-sensitive adhesive for waterproofing membrane provided in this example, its raw material formula is shown in Table 1,

[0033] in,

[0034] The thermoplastic elastomer is SIS, which comes from Yueyang Chemical Rubber Products, and the brand name is SIS-4019.

[0035] The matrix resin is C5 hydrogenated petroleum resin, which comes from Zhejiang Henghe Petrochemical Co., Ltd., and the brand is H5-1001.

[0036] The tackifying resin is hydrogenated rosin resin, which comes from Guangdong Kemao Forestry Chemical Co., Ltd., and the brand name is KS-2100.

[0037] The plasticizer is compounded with naphthenic oil and chlorinated paraffin at a mass ratio of 3:1, the grade of naphthenic oil is KN4010, and the grade of chlorinated paraffin is 52#.

[0038] As the polyisobutylene, polyisobutylene with a number average molecular weight of 1000 was used.

[0039] The coupling agent is KH550.

[0040] The inorga...

Embodiment 2

[0044] The high-temperature-resistant non-bitumen-based hot-melt pressure-sensitive adhesive for waterproofing membrane provided in this example has a raw material formula as shown in Table 1, and the difference from Example 1 lies in:

[0045] The thermoplastic elastomer is SIS, which comes from Taiwan Rubber Co., Ltd., and the grades SIS-4114 and SIS-4116 are compounded at a mass ratio of 2:1.

[0046] The matrix resin is a compound of C5 hydrogenated petroleum resin and C5 petroleum resin at a mass ratio of 1:3.

[0047] The tackifying resin is hydrogenated rosin resin.

[0048] No inorganic fillers added

Embodiment 3

[0050] The high-temperature-resistant non-bitumen-based hot-melt pressure-sensitive adhesive for waterproofing membrane provided in this example has a raw material formula as shown in Table 1, and the difference from Example 1 lies in:

[0051] The matrix resin is compounded with C5 petroleum resin and DCPD resin at a mass ratio of 1:1.

[0052] The tackifying resin is a mixture of terpene phenol resin and hydrogenated rosin resin in a mass ratio of 5:2.

[0053] The inorganic filler is Shiyuan titanium dioxide, the grade is R-930.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com