Liquid crystal film material, liquid crystal alignment agent, liquid crystal alignment film, preparation method of liquid crystal alignment film and liquid crystal display element

A liquid crystal alignment film and liquid crystal alignment agent technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of reduced brightness, interference with grayscale display, and reduced quality of liquid crystal display, achieving high contrast and suppressing display contrast Good effect of drop and afterimage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

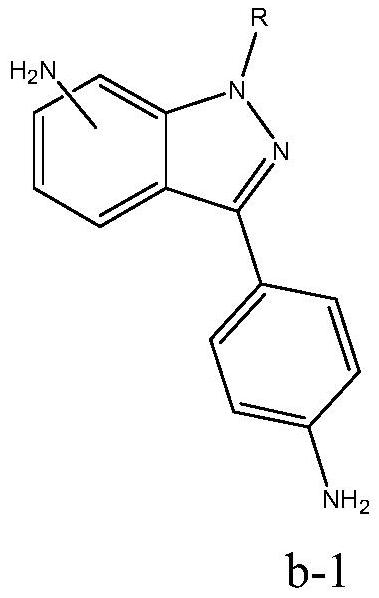

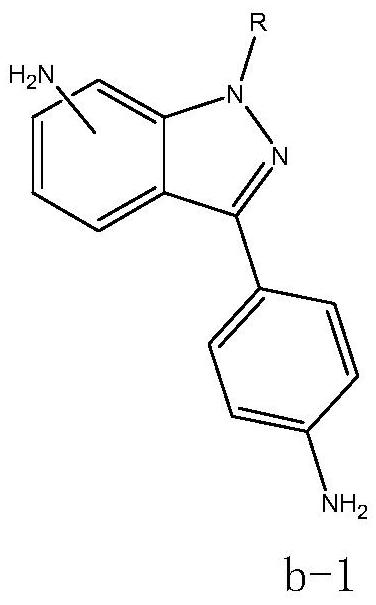

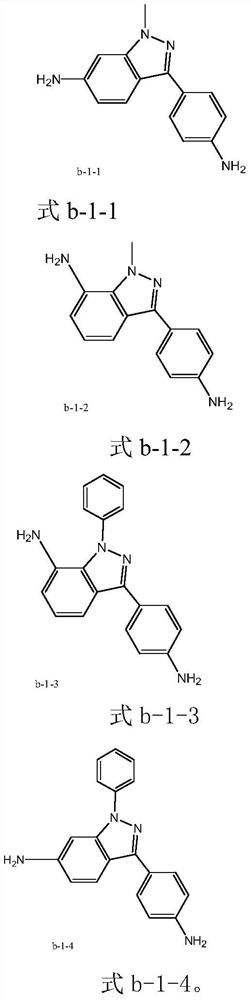

[0118] b-1-1. Synthetic route

[0119]

[0120] Synthesis of compound b-1-1a

[0121] Get compound 4-amino 2-methyl ether base iodobenzene 16.57 (25mmol), compound 4-dihydroxyboryl aniline (37.3mmol, NaI3.75g (25mmol.), NaI 2 CO 3 5.3g (50mmol), PivOH1.91g (18.75mmol), CsOH·H 2 O20.99g (125mmol), CHCl 3 17.7g (75mmol), ethylene glycol (200mL) was added to a 500ml flask, heated to 120°C in an oil bath, and reacted for 24h. Detected by TLC, after the reaction was complete, cooled to room temperature, extracted with EA, washed with saturated brine, dried with anhydrous sodium sulfate, and the solvent was removed by rotary evaporation. [M+1]=257.30PE / The product b-1-1a was obtained by EA column chromatography with a yield of 80%.

[0122] Synthesis of compound b-1-1b

[0123] Take 5.68g (20mmol) of compound b-1-1a, 0.92g (20mmol) of methylhydrazine, ethanol (200ml), and acetic acid (60ml) into a 500ml round-bottomed flask, heat to reflux in an oil bath, and detect with T...

Synthetic example A-1-1

[0151] Under a nitrogen atmosphere, drop 1-(4-(4-heptylcyclohexyl)phenoxy)-2,4-diaminobenzene (53.2g, 140mmol) into a 500mL three-necked round-bottomed flask (the following Abbreviated as b-2-8), p-phenylenediamine (2.16g, 20 mmol) (hereinafter referred to as b-2-1), p-aminodiphenylethane (4.23g, 20 mmol) (hereinafter referred to as b-2 -3) and 96.12 g of NMP, the resulting suspension was stirred until a yellow solution was obtained. Then 38.54g (180 mmol) of 2,3,5-tricarboxycyclopentylacetic dianhydride (hereinafter abbreviated as a-2) plus 0.40 g (4 mmol) of n-hexylamine as a molecular weight regulator and 96.12 g of NMP were added to the system. The reaction was exothermic and stirred at room temperature for 4 hours to obtain polyamic acid polymer A-1-1 with a solid content of 20% dissolved in NMP. As a result of confirming the molecular weight of polymer A-1-1 by GPC, the number average molecular weight (Mn) was 8250 g / mol. .

[0152] Synthesis Examples A-1-2 to A-1-20 ...

Embodiment 1

[0188] The liquid crystal aligning agent of Example 1 was coated on a piece of the first glass substrate with ITO electrodes by printing to form a pre-coat layer, and left for 10 minutes to delaminate the alignment layer and the conductive layer of the alignment film. After pre-curing (hot plate, 85°C, 10 minutes), main curing (circulation oven, 225°C, 50 minutes), exposure (254nm polarized light, 5mW / cm 2 , 1000mj / cm 2 ) will obtain the first glass substrate with the liquid crystal alignment film of embodiment 1 formed on the ITO electrode.

[0189] The liquid crystal aligning agent of Example 1 was coated on a second glass substrate without an ITO electrode by spin coating to form a pre-coat layer. The second glass substrate on which the liquid crystal aligning film of Example 1 is formed is obtained after the above-mentioned pre-curing, main curing, and light exposure.

[0190]An ultraviolet curable glue is coated on the periphery of one of the first glass substrate and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com