Preparation method of vapor chamber upper cover plate and vapor chamber

A technology of vapor chamber and cover plate, which is applied in the field of heat dissipation. It can solve the problems of poor bonding force between capillary structure and cover plate, capillary performance cannot be kept stable, and complicated sintering process, so as to broaden the application range, improve strength, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

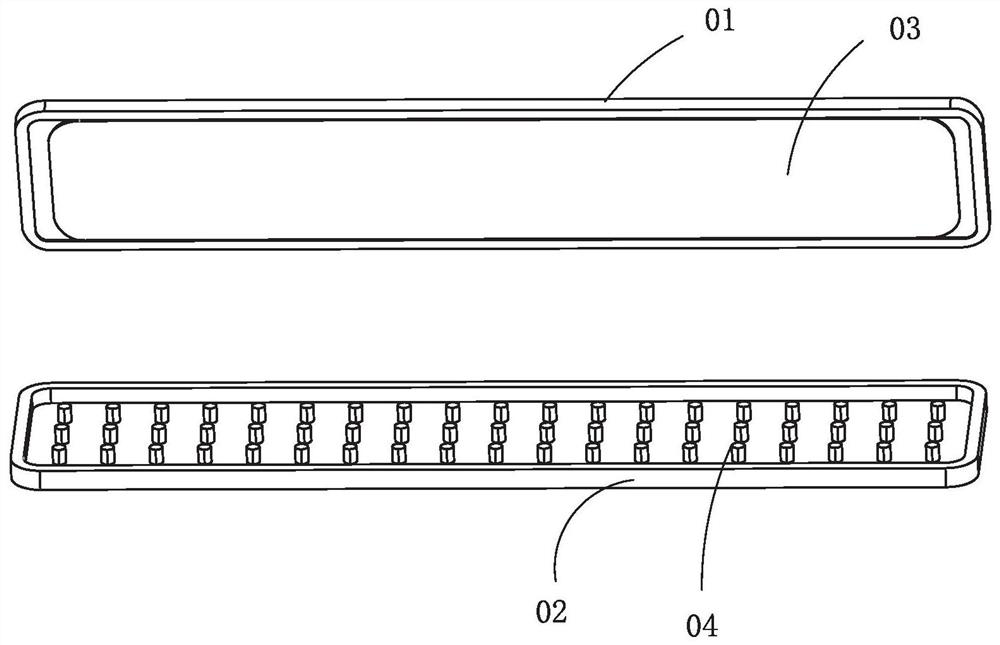

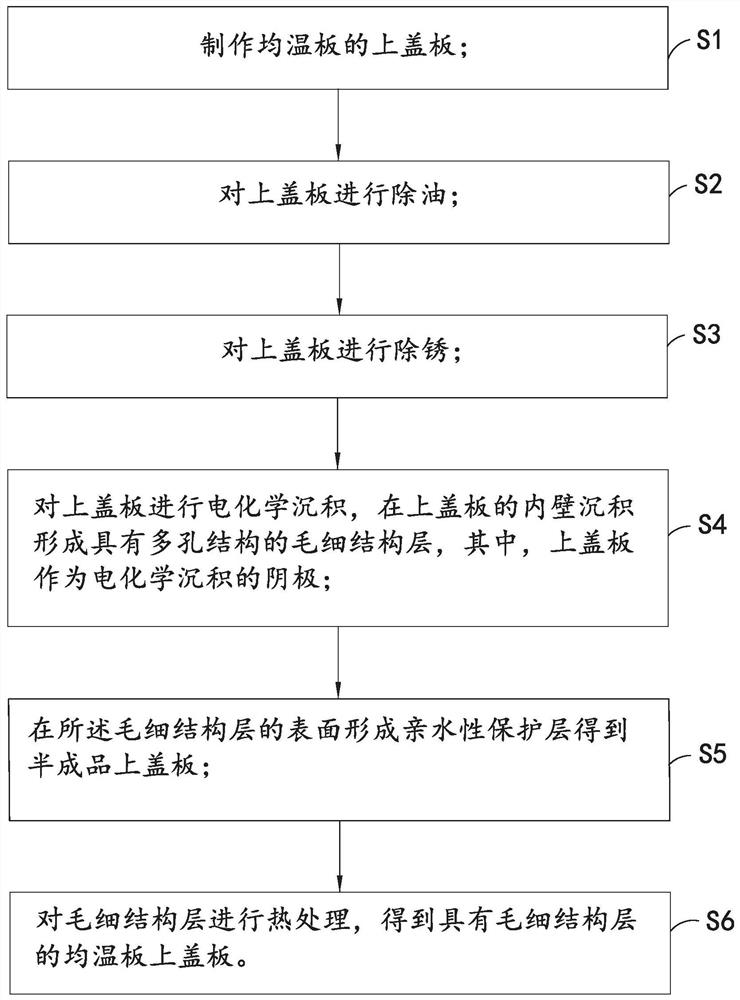

[0066] S1. Fabrication of the upper cover and the lower cover: obtained by etching the copper sheet, the thickness of the copper sheet is between 0.05mm-0.4mm.

[0067] S2. Degreasing: The solution used is a weakly alkaline degreasing solution, the ingredients include trisodium phosphate 50g / L, sodium carbonate 20g / L, sodium metasilicate 20g / L, OP emulsifier 3ml / L, and the solution temperature is 50°C , Put the upper cover plate into the solution for cathodic electrolysis for 5min, the current density is 2A / dm 2 , and then immediately rinse with pure water.

[0068] S3. Rust removal: use a rust remover with a mixed acid solution, and its ingredients include sulfuric acid 200g / L, nitric acid 10g / L, hydrochloric acid 5g / L, urea 10g / L, and benzotriazole 0.5g / L. Soak the upper cover in the solution for 3 minutes at room temperature, and then immediately wash it with pure water.

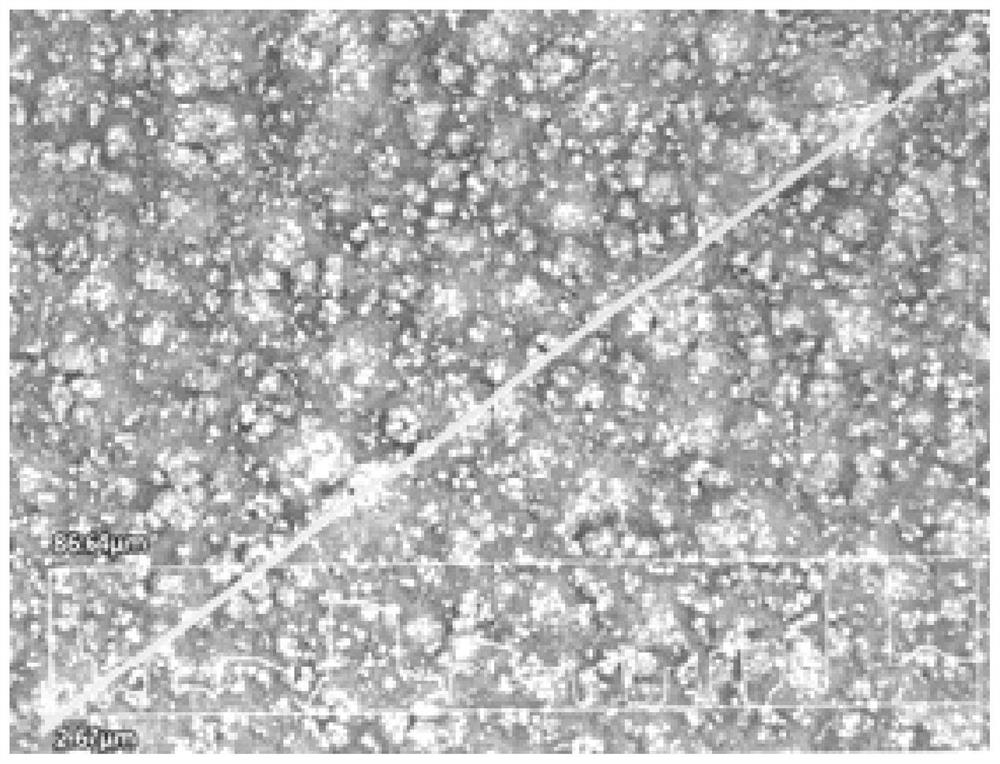

[0069] S4. Electrochemical deposition of copper: using solution is the mixture of copper sulfate 80g...

Embodiment 2

[0073] S1. Fabrication of the upper cover and the lower cover: obtained by etching the copper sheet, the thickness of the copper sheet is between 0.05mm-0.4mm.

[0074] S2. Degreasing: The solution used is a weakly alkaline degreasing solution, the ingredients include trisodium phosphate 20g / L, sodium carbonate 40g / L, sodium metasilicate 30g / L, OP emulsifier 3ml / L, and the solution temperature is 50°C , put the upper cover plate into the solution for cathodic electrolysis for 3 minutes, and the current density is 3A / dm 2 , and then immediately rinse with pure water.

[0075] S3. Rust removal: use a rust remover with a mixed acid solution, and its ingredients include sulfuric acid 150g / L, nitric acid 15g / L, hydrochloric acid 5g / L, urea 5g / L, and benzotriazole 0.8g / L. Soak the upper cover in the solution for 5 minutes at room temperature, and then immediately wash it with pure water.

[0076] S4. Electrochemical deposition of copper: using solution is the mixture of copper sul...

Embodiment 3

[0080] S1. Fabrication of the upper cover and the lower cover: obtained by etching the copper sheet, the thickness of the copper sheet is between 0.05mm-0.4mm.

[0081]S2. Degreasing: The solution used is a weakly alkaline degreasing solution, the ingredients include 40g / L trisodium phosphate, 30g / L sodium carbonate, 10g / L sodium metasilicate, 1ml / L OP emulsifier, and the solution temperature is 60°C , Put the upper cover plate into the solution for cathodic electrolysis for 2min, the current density is 5A / dm 2 , and then immediately rinse with pure water.

[0082] S3. Rust removal: Use a rust remover with a mixed acid solution, and its ingredients include sulfuric acid 250g / L, nitric acid 5g / L, hydrochloric acid 10g / L, urea 10g / L, and benzotriazole 1g / L. Soak the upper cover in the solution for 2 minutes at room temperature, and then immediately wash it with pure water.

[0083] S4. Electrochemical deposition of copper: using solution is the mixture of copper sulfate 30g / L,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com