Heavy metal ion passivation stabilizer for flowback fluid treatment residues and preparation method

A technology for heavy metal ions and flowback liquid, which is applied in chemical instruments and methods, water/sewage treatment, mining wastewater treatment, etc. Activity, the effect of solving the toxicity and pollution of heavy metal ions, and the convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In order to overcome the toxicity and pollution of heavy metal ions caused by the existing waste liquid residues to the environment, the present invention provides a heavy metal ion passivation stabilizer and preparation method for flowback liquid treatment residues. The formula provided by the present invention can effectively improve oil field measures The heavy metal ion stabilization efficiency of the flowback liquid treatment residue can effectively reduce the activity of heavy metals in the waste liquid residue, and solve the problem of heavy metal ion toxicity and pollution caused by the waste liquid residue to the environment.

[0022] A heavy metal ion passivation stabilizer for flowback liquid treatment residue, which is composed of the following components in weight ratio: 0.5-1% sodium sulfide, 20-30% potassium dihydrogen phosphate, 10-15% dithiocarbamate %, heavy metal adsorbent 55-65%.

[0023] Preferably, the heavy metal adsorbent includes lycyrrhizae and...

Embodiment 2

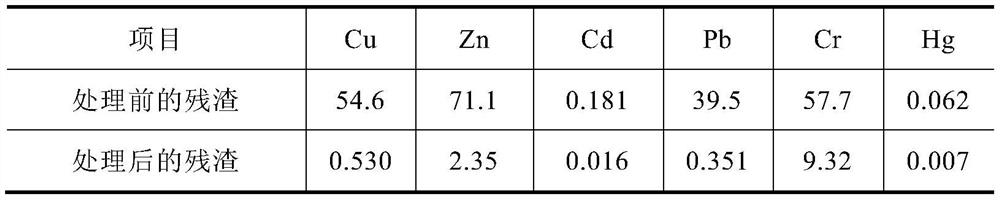

[0036] Based on the basis of Example 1, in this example, preferably, a heavy metal ion passivation stabilizer for flowback liquid treatment residue is composed of the following components in weight ratio: 0.6% sodium sulfide, 22.4% potassium dihydrogen phosphate %, dithiocarbamate 13.5%, heavy metal adsorbent 63.5%.

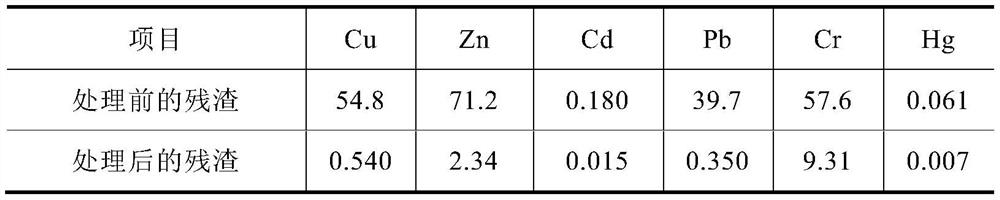

[0037] The preparation process of the heavy metal adsorbent in this example is as follows: pulverize lycyrrhizae and lycyrrhizae into powder, grind the mushroom residues of Pleurotus ostreatus and air-dry them in the sun for simple sterilization. The weight component of 42wt% oyster mushroom residue is stirred evenly. Take 0.6% of sodium sulfide, 22.4% of potassium dihydrogen phosphate, 13.5% of dithiocarbamate, and 63.5% of heavy metal adsorbent by weight of the formula, mix them in sequence, stir evenly; pack into bags and seal to form a finished product. Apply the heavy metal ion passivation stabilizer formula of the present invention to treat oilfield measur...

Embodiment 3

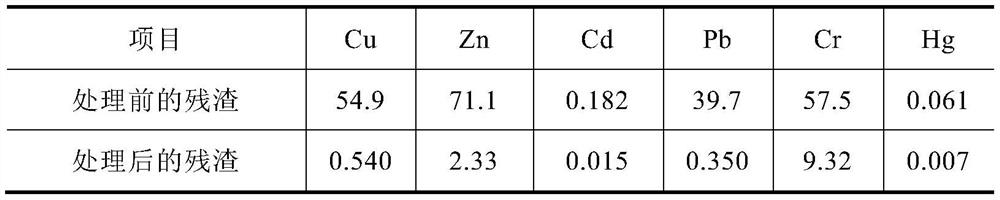

[0041] Based on the basis of Example 1, in the present example, a heavy metal ion passivation stabilizer for flowback liquid treatment residue is composed of the following components by weight ratio: sodium sulfide 0.5%, potassium dihydrogen phosphate 25%, dihydrogen phosphate Thiocarbamate 15%, heavy metal adsorbent 59.5%.

[0042] The preparation process of the heavy metal adsorbent in this example is as follows: pulverize lycyrrhizae and lycyrrhizae into powder, grind the pleurotus ostreatus slag and air-dry it in the sun for simple sterilization. After passing through an 80-mesh sieve, the The weight component of 43wt% oyster mushroom residue is stirred evenly. The sodium sulfide, potassium dihydrogen phosphate, dithiocarbamate, and heavy metal adsorbent are mixed in sequence by the weight of the formula, stirred evenly; bagged and sealed to form a finished product. Apply the formula of the heavy metal ion passivation stabilizer provided by the present invention to proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com