Preparation method of graphene modified cement and product thereof

A graphene modification and graphene technology, which is applied in the field of modified cement, can solve the problems of cracks, low tensile strength and toughness of cement, and improve tensile strength and toughness, prevent agglomeration, and improve compressive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

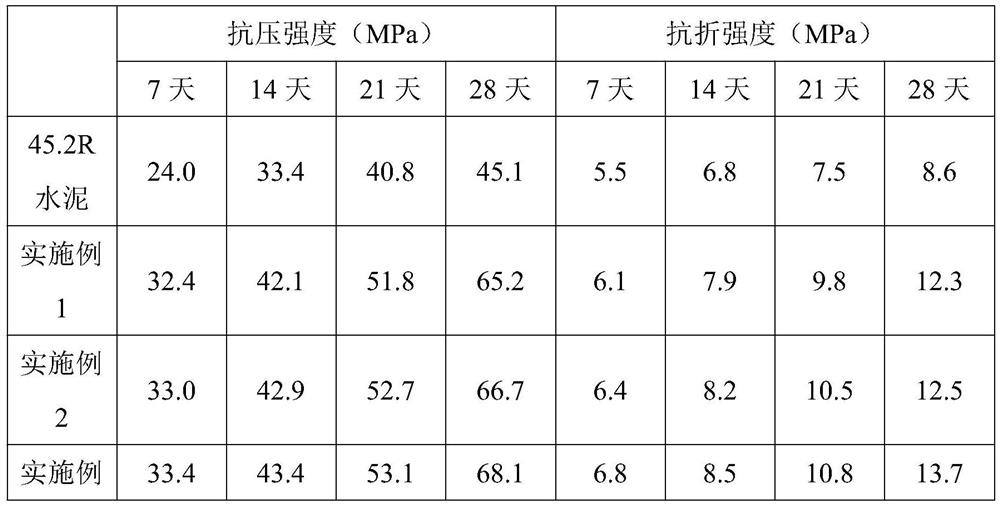

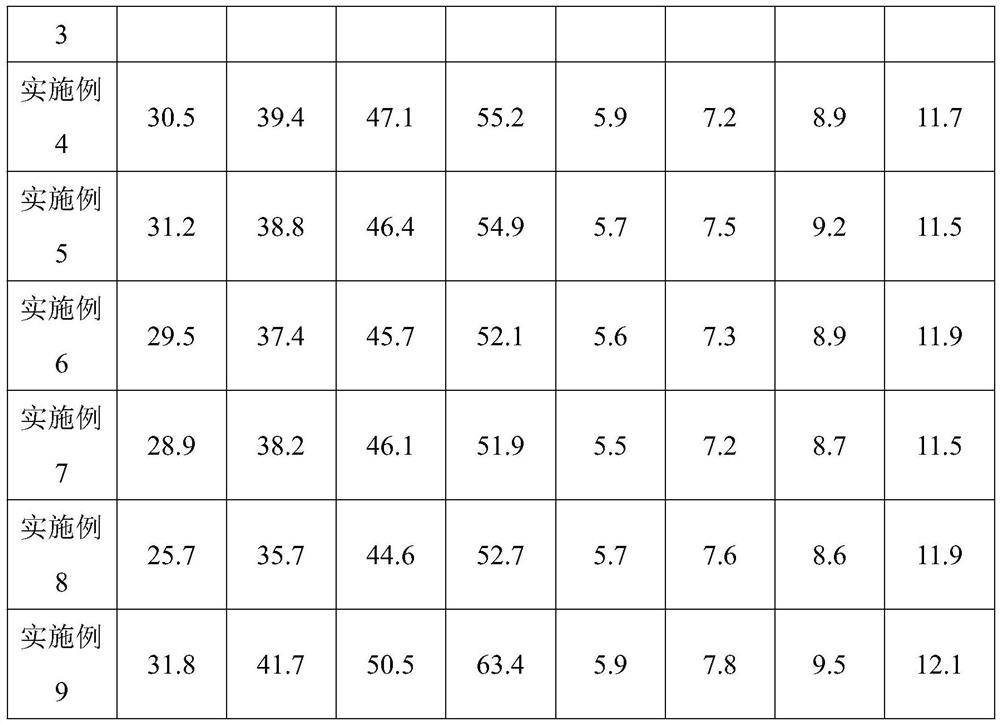

Examples

Embodiment 1

[0025] (1) Put 10 g of graphene oxide in 200 mL N, N-dimethylformamide solution for ultrasonic dispersion, heat to 55°C, add 0.05 mol of isophorone diisocyanate under nitrogen atmosphere and react for 12 hours, then add 0.05 mol of isobutyl Continue to react with alcohol for 8h, add 0.05mol hydrazine hydrate to continue to react for 6h, then filter, and the resulting product is washed, dried, and pulverized to obtain polyurethane-modified graphene;

[0026] (2) Take polyethylene glycol, tetrabutyl titanate, and polyurethane-modified graphene at a mass ratio of 1:1:3 and place them in an ethanol solution for ultrasonic dispersion, use hydrochloric acid to adjust the pH of the solution to 4, and place them in a water bath at 45°C After hydrolysis for 4 hours under ambient conditions, use sodium hydroxide to adjust the pH value of the solution to 9, let it stand and age for 24 hours, filter and dry to obtain a polyethylene glycol / titanium dioxide / polyurethane modified graphene com...

Embodiment 2

[0029] (1) Put 15g of graphene oxide in 150mL N, N-dimethylformamide solution for ultrasonic dispersion, heat to 40°C, add 0.07mol of isophorone diisocyanate under nitrogen atmosphere and react for 12h, then add 0.05mol of isobutyl Continue to react with alcohol for 8h, add 0.7mol hydrazine hydrate to continue to react for 6h, then filter, and the resulting product is washed, dried, and pulverized to obtain polyurethane-modified graphene;

[0030] (2) Take polyethylene glycol, tetrabutyl titanate, and polyurethane-modified graphene in an ethanol solution at a mass ratio of 1:0.5:5 for ultrasonic dispersion, use hydrochloric acid to adjust the pH of the solution to 5, and place in a 50°C water bath After hydrolysis for 4 hours under ambient conditions, use sodium hydroxide to adjust the pH value of the solution to 10, leave it to age for 48 hours, filter and dry to obtain a polyethylene glycol / titanium dioxide / polyurethane modified graphene composite material;

[0031] (3) the ...

Embodiment 3

[0033] (1) Put 20g of graphene oxide in 200mL N, N-dimethylformamide solution for ultrasonic dispersion, heat to 50°C, add 0.1mol of isophorone diisocyanate under nitrogen atmosphere and react for 12h, then add 0.05mol of isobutyl Continue to react with alcohol for 8h, add 0.1mol hydrazine hydrate to continue to react for 6h, then filter, and the resulting product is washed, dried, and pulverized to obtain polyurethane-modified graphene;

[0034] (2) Take polyethylene glycol, tetrabutyl titanate, and polyurethane-modified graphene in an ethanol solution at a mass ratio of 2:1:3 for ultrasonic dispersion, and use hydrochloric acid to adjust the pH of the solution to 4, and place them in a 50°C water bath After hydrolysis for 4 hours under ambient conditions, use sodium hydroxide to adjust the pH value of the solution to 9, let it stand and age for 48 hours, filter and dry to obtain polyethylene glycol / titanium dioxide / polyurethane modified graphene composite material;

[0035] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com