Lead-free piezoelectric ceramic for medical ultrasonic transducer as well as preparation method and application of lead-free piezoelectric ceramic

An ultrasonic transducer, lead-free piezoelectric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the long heating and cooling time , high equipment cost, difficult industrial production and other problems, to achieve the effect of reducing sintering temperature, improving production efficiency and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

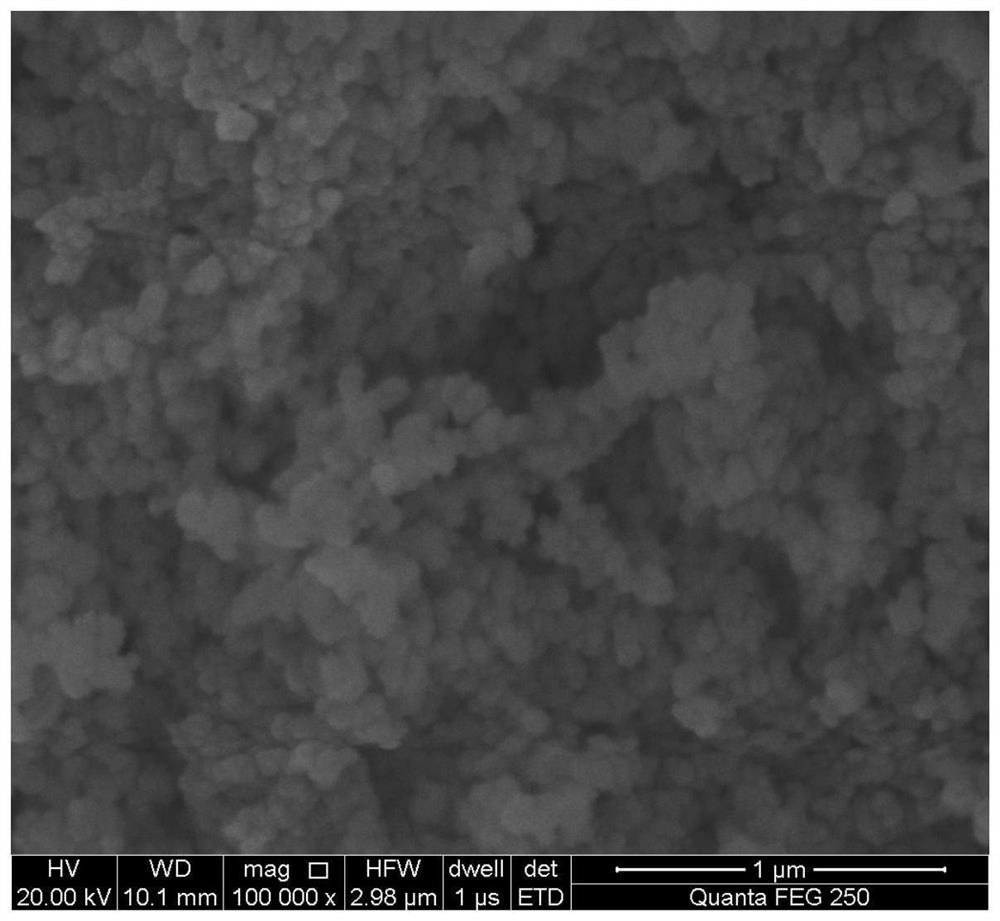

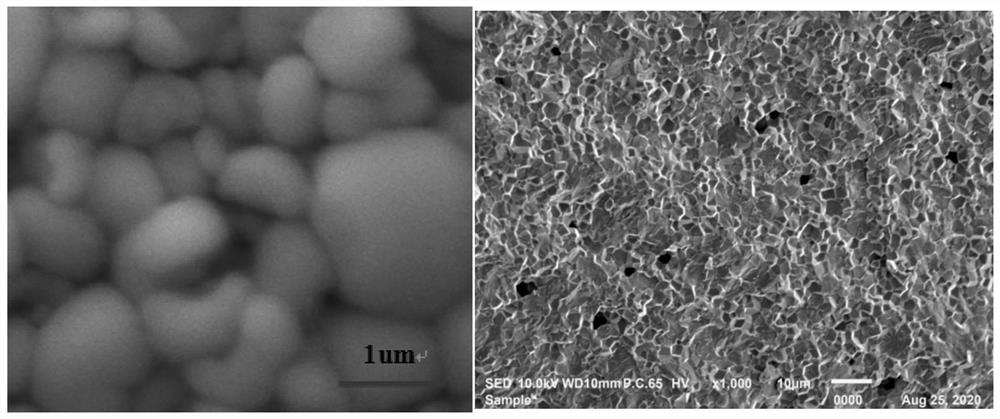

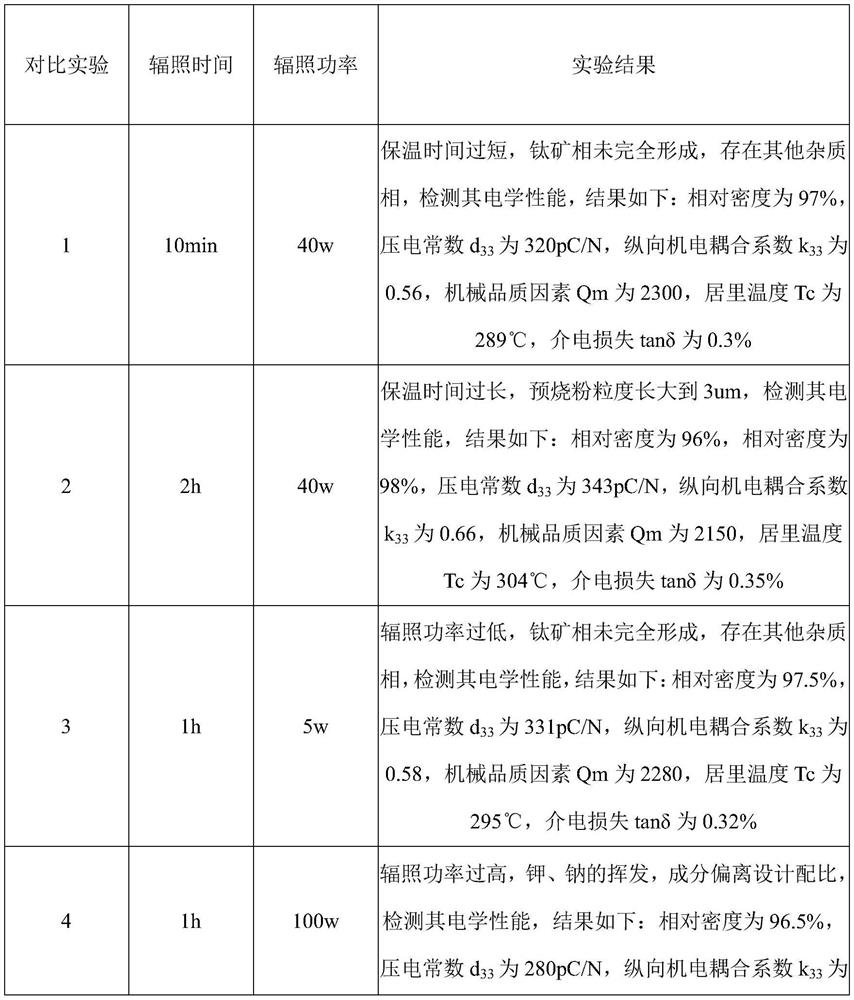

Image

Examples

Embodiment 1

[0049] A preparation method of lead-free piezoelectric ceramics for medical ultrasonic transducers, the process is as follows:

[0050] A. Formulation design: according to 0.96(K 0.5 Na 0.5 )NbO 3 -0.04Bi 0.5 Na 0.5 ZrO 3 (wt.%) stoichiometric ratio with the raw material Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 、 Bi 2 o 3 , ZrO 2 ;

[0051] B. Ultrasonic irradiation: Dry the weighed raw materials and put them into a beaker together with ethanol. The mass ratio of raw materials and ethanol is 1:1. Ultrasonic irradiation treatment is carried out in the ultrasonic irradiation equipment. Among them, the irradiation time is 0.5h, the irradiation temperature is 90°C, and the irradiation power is 30w;

[0052] C. Drying & sieving: the irradiated powder is kept in a drying oven at 80°C for 12 hours, and then passed through an 80-mesh sieve;

[0053] D. Calcination: put the sieved powder into a corundum crucible, and calcinate in a sintering furnace to synthesize a pre-calcined p...

Embodiment 2

[0059]A preparation method of lead-free piezoelectric ceramics for medical ultrasonic transducers, the process is as follows:

[0060] A. Formulation design: according to 0.94(K 0.5 Na 0.5 )NbO 3 +0.06Bi 0.5 Na 0.5 ZrO 3 (wt.%) stoichiometric ratio with the raw material Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 、 Bi 2 o 3 , ZrO 2 ;

[0061] B. Ultrasonic irradiation: Dry the weighed raw materials and put them into a beaker together with ethanol. The mass ratio of raw materials and ethanol is 1:1. Ultrasonic irradiation treatment is carried out in the ultrasonic irradiation equipment. Among them, the irradiation time is 1h, the irradiation temperature is 70°C, and the irradiation power is 40w;

[0062] C. Drying & sieving: the irradiated powder is kept in a drying oven at 80°C for 12 hours, and then passed through an 80-mesh sieve;

[0063] D. Calcination: put the sieved powder into a corundum crucible, and calcinate in a sintering furnace to synthesize a pre-calcined powd...

Embodiment 3

[0070] A preparation method of lead-free piezoelectric ceramics for medical ultrasonic transducers, the process is as follows:

[0071] A. Formulation design: according to 0.92(K 0.5 Na 0.5 )NbO 3 +0.08Bi 0.5 Na 0.5 ZrO 3 (wt.%) stoichiometric ratio with the raw material Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 、 Bi 2 o 3 , ZrO 2 ;

[0072] B. Ultrasonic irradiation: Dry the weighed raw materials and put them into a beaker together with ethanol. The mass ratio of raw materials and ethanol is 1:1. Ultrasonic irradiation treatment is carried out in the ultrasonic irradiation equipment. Among them, the irradiation time is 0.5h, the irradiation temperature is 90°C, and the irradiation power is 30w;

[0073] C. Drying & sieving: the irradiated powder is kept in a drying oven at 80°C for 12 hours, and then passed through an 80-mesh sieve;

[0074] D. Calcination: put the sieved powder into a corundum crucible, and calcinate in a sintering furnace to synthesize a pre-calcined p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric constant | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com