Preparation process of 1, 3-cyclohexanediamine

A technology for the preparation of cyclohexyldimethylamine, which is applied in the field of preparation technology of 1,3-cyclohexanedimethylamine, can solve the problems of high cost, harsh reaction conditions, poor selectivity, etc., and achieve mild reaction conditions and high reaction yield. The effect of high efficiency and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

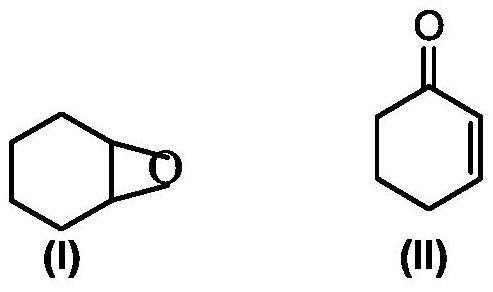

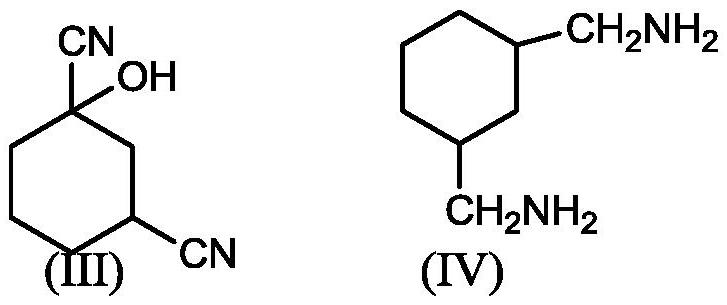

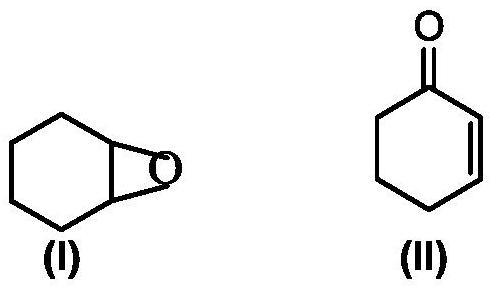

Image

Examples

Embodiment 1

[0052] [Preparation Example 1] Preparation of Isomerization Dehydrogenation Catalysts A~F

[0053] Prepare isomerization dehydrogenation catalyst A~F respectively according to different conditions in table 1, preparation method is as follows:

[0054] Break the copper-based catalyst into powder, prepare 2500mL of a certain concentration of sodium phosphate solution, add 500g of copper-based catalyst powder into the sodium phosphate aqueous solution, shake it well, and place it in a water bath constant temperature oscillator for 24 hours. During this period, keep the temperature of the water bath at Around 80°C, the shaking speed is 140r / min. Then maintain the temperature and continue to shake, dropwise add 2500mL lithium chloride solution, control the dropping rate to finish adding within 1.5h, continue to shake at this temperature for 6h, filter, place the obtained sample in concentrated ammonia water, shake well, place Put them in a constant temperature shaker in a water ba...

Embodiment 2-11

[0081] Carry out embodiment 2~11 according to the method in embodiment 1, difference only lies in the difference of reaction condition and result in table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com