A kind of raw material composition for preparing photocurable resin, photocurable resin prepared therefrom and application thereof

A technology of raw material composition and photocurable resin, which is applied in the field of curable resin synthesis, can solve the problems of reduced impact resistance, etc., and achieve the effects of low shrinkage, excellent mechanical and thermal properties, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

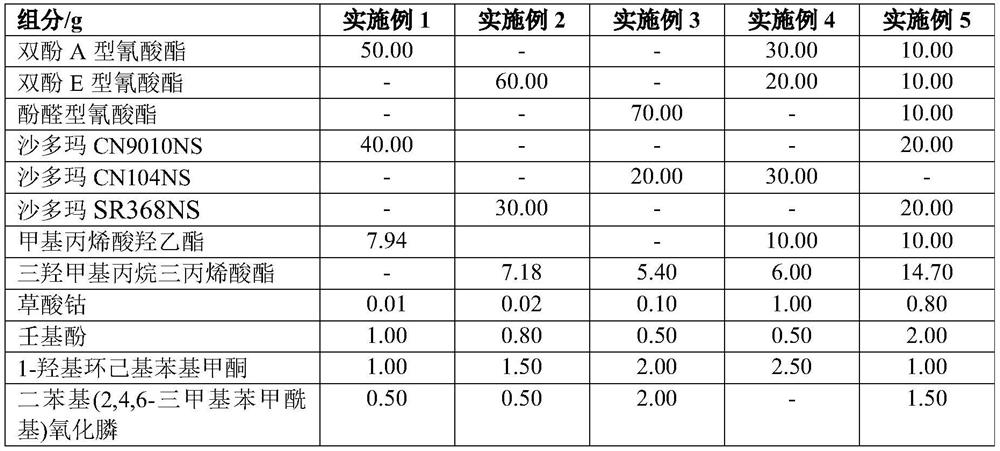

[0060] The preparation of embodiment 1-5 photocurable IPN resin

[0061] The preparation steps of the light-cured IPN resin are as follows:

[0062] 1. Ingredient process

[0063] The cyanate ester was dissolved in the photocurable prepolymer in the beaker 1, and it stirred at 60 degreeC for 10 minutes. Mix the catalyst and part of the diluent in beaker 2, pour into beaker 1 after sonicating for 30 minutes, rinse beaker 2 with the remaining diluent and pour into beaker 1, then add photoinitiator and stir for 10 minutes. The beaker 1 was placed in a vacuum box, evacuated for 10 minutes, and the air bubbles were removed for later use.

[0064] 2. Curing process

[0065] 1) Ultraviolet light curing: pour the mixture prepared by the above batching process into a mold, and irradiate it under ultraviolet light with a power of 400W for 200 seconds to obtain a preliminary cured product.

[0066] 2) Thermal curing: the preliminary cured product is placed in a temperature-programmed...

Embodiment 6

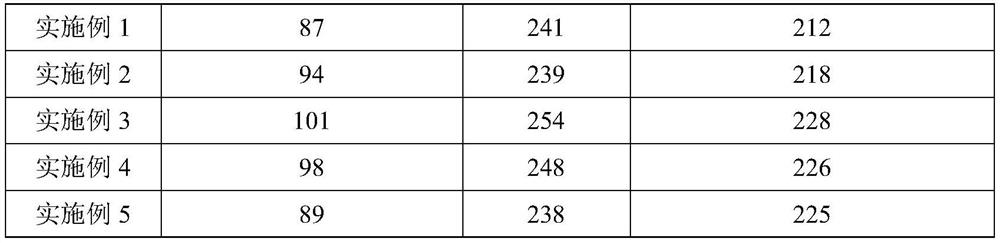

[0070] Example 6 Performance test of light-cured IPN resin

[0071] The photocurable IPN resin samples prepared in the above Examples 1-5 were tested for mechanical and thermal properties.

[0072] The tensile strength was measured on a universal mechanical property testing machine according to the ISO527 standard; the glass transition temperature Tg was obtained from Tanδ on a dynamic thermomechanical analyzer DMA, the temperature range was 20 to 300°C, the heating rate was 3°C / min, and the vibration frequency was 1.0Hz. The sample size is 33mm×13mm×3.0mm; the thermal deformation temperature is measured on the Vicat tester, and the sample size is 80mm×10mm×3.0mm.

[0073] Table 2 Properties of light-cured IPN resins

[0074]

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com