A kind of lubricant and its preparation method and application

A lubricant and reaction technology, applied in the field of lubricants and their preparation, can solve the problem that water-based lubricants cannot have both low-foaming and super-lubricating properties at the same time, achieve excellent lubricity, low production costs, and avoid negative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The embodiment of the present application provides a lubricant, and the specific preparation method includes:

[0042] (1) The isononanoic acid of 46% mass percentage is dropped in the reactor, is warming up to 90 ℃, for subsequent use;

[0043] (2) The alcohol amine mixture of 54% mass percent is slowly dropped into the reactor containing isononanoic acid, and the alcohol amine mixture includes diisopropanolamine and diethanolamine; the mass ratio of diisopropanolamine and diethanolamine is 4: 1;

[0044] (3) Put the catalyst 18-crown ether-6 of 0.15% by mass of the sum of the mass of isononanoic acid and alcohol amine mixture into the reactor, raise the temperature to 120°C, react at this temperature for about 4h, and turn on the vacuum pump at the same time To discharge the water generated by the reaction, stop heating when no more water is distilled out.

[0045] (4) naturally cool to room temperature, discharge, marked as embodiment 1.

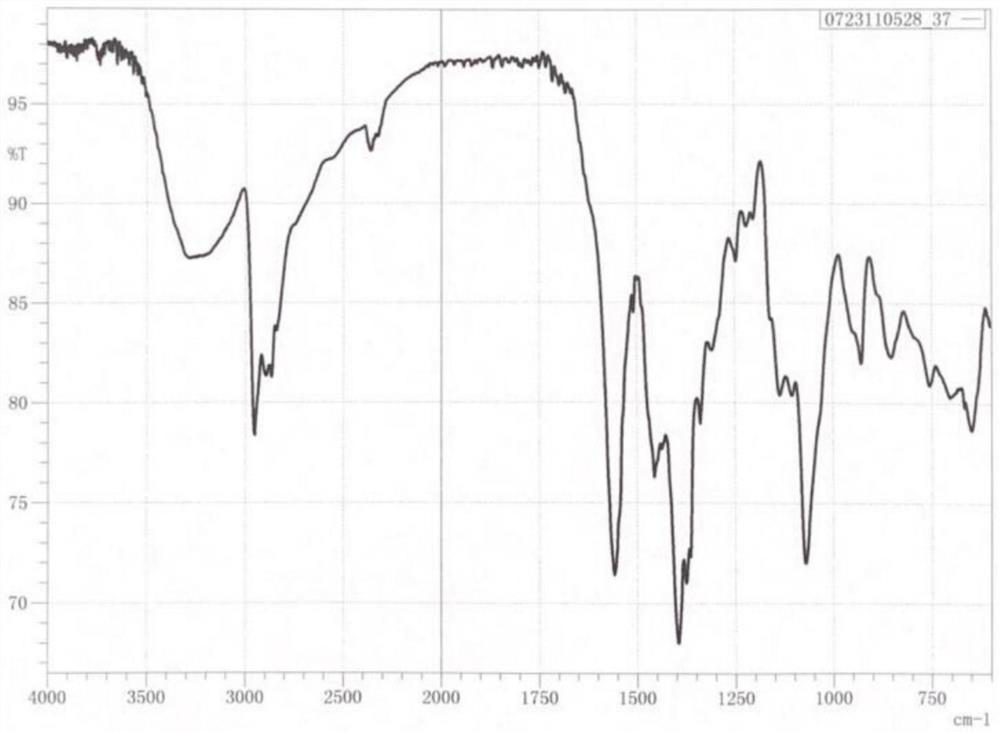

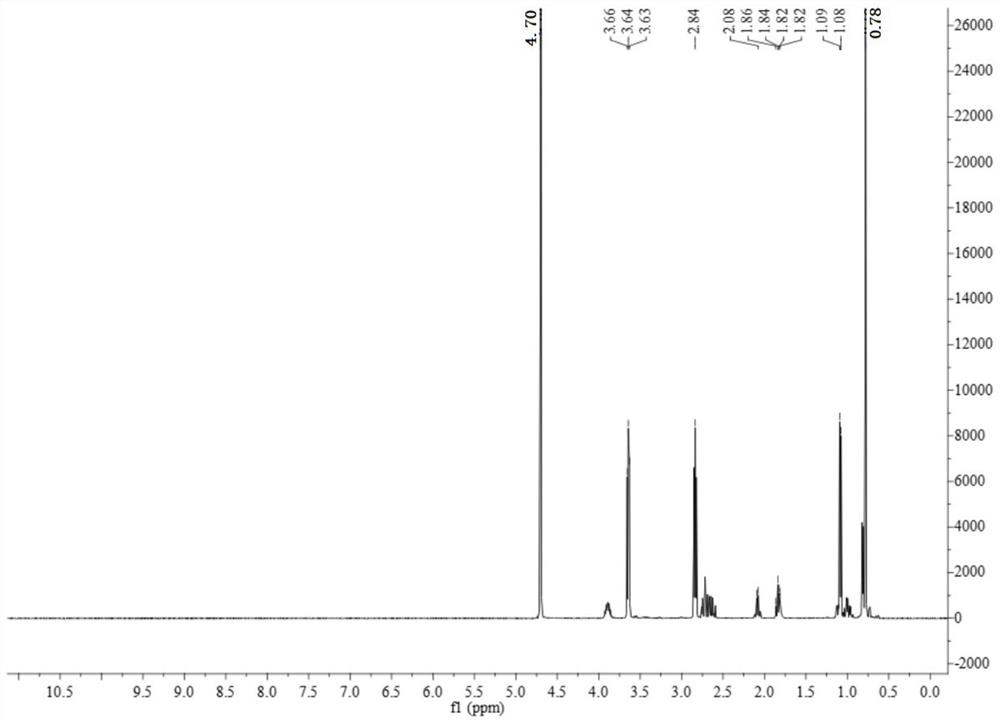

[0046] Carry out infrare...

Embodiment 2

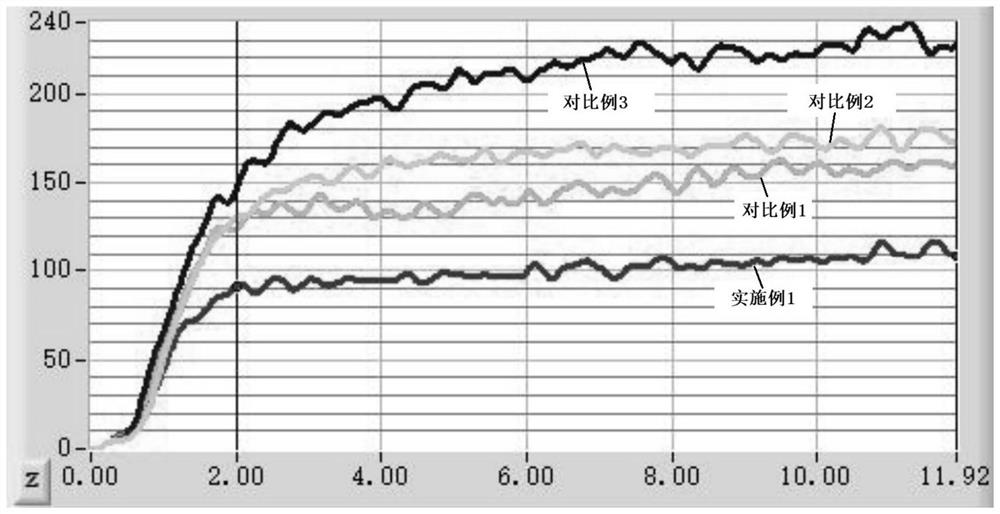

[0048] The embodiment of the present application provides the tapping test of Example 1 and Comparative Examples 1 to 3, and the specific steps include:

[0049] Use the simulation testing machine to directly conduct the tapping test on the metal material with the reserved hole, and use the average torque value to evaluate the lubricating performance of its processing. Theoretically, the lower the tapping torque value, the better the lubricity.

[0050] Respectively with embodiment 1, comparative example 1 (phosphoric acid ester), comparative example 2 (tall oleic acid diethanolamide) and comparative example 3 (triethanolamine oleic acid soap) as solute, tap water as solvent, preparation embodiment 1, pair 1% working solutions of Example 1 (phosphate ester), Comparative Example 2 (tall oleic acid diethanolamide) and Comparative Example 3 (triethanolamine oleic acid soap).

[0051] The 1% working solutions of Example 1, Comparative Example 1 (phosphate ester), Comparative Exam...

Embodiment 3

[0056] The embodiment of the present application provides the CSM reciprocating friction test of embodiment 1 and comparative examples 1 to 3, and the specific steps include:

[0057] Respectively with embodiment 1, comparative example 1 (phosphoric acid ester), comparative example 2 (tall oleic acid diethanolamide) and comparative example 3 (triethanolamine oleic acid soap) as solute, tap water as solvent, preparation embodiment 1, pair 1% working solutions of Example 1 (phosphate ester), Comparative Example 2 (tall oleic acid diethanolamide) and Comparative Example 3 (triethanolamine oleic acid soap).

[0058] Utilize CSM reciprocating friction testing machine, be 10N at load, be that test embodiment 1, comparative example 1 (phosphoric acid ester), comparative example 2 (tall oleic acid diethanolamide) and comparative example 3 ( triethanolamine oleic acid soap) to obtain the coefficient of friction. CSM reciprocating friction test, in theory, the lower the coefficient of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com