Lithium-sulfur battery gel-state positive electrode and preparation method thereof

A lithium-sulfur battery, gel state technology, applied in the direction of gel electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of unfavorable battery volume or mass specific energy, limited improvement of battery performance, difficulty in reducing the amount of electrolyte, etc. , to achieve the effects of good operability, performance improvement and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A preparation method of a lithium-sulfur battery gel state positive electrode of the present invention comprises the following steps:

[0050] S1. Mix elemental sulfur and lithium sulfide in a molar ratio of 7:1 to 3:1 and add them into a high dielectric constant solvent, fully dissolve and react to prepare an electrolyte solution containing lithium polysulfide;

[0051] S2. After mixing the conductive polymer and the easy-gelling polymer in a solvent at a mass ratio of 1:9 to 5:5, coat it on a support, and dry it at 25 to 85 degrees for 12 to 48 hours to obtain a polymer skeleton;

[0052] S3. Soak the polymer skeleton in the electrolyte solution for 0.5-24 hours, or inject the electrolyte solution into the polymer skeleton, form a gel layer after fully swelling, and obtain a gel state positive electrode.

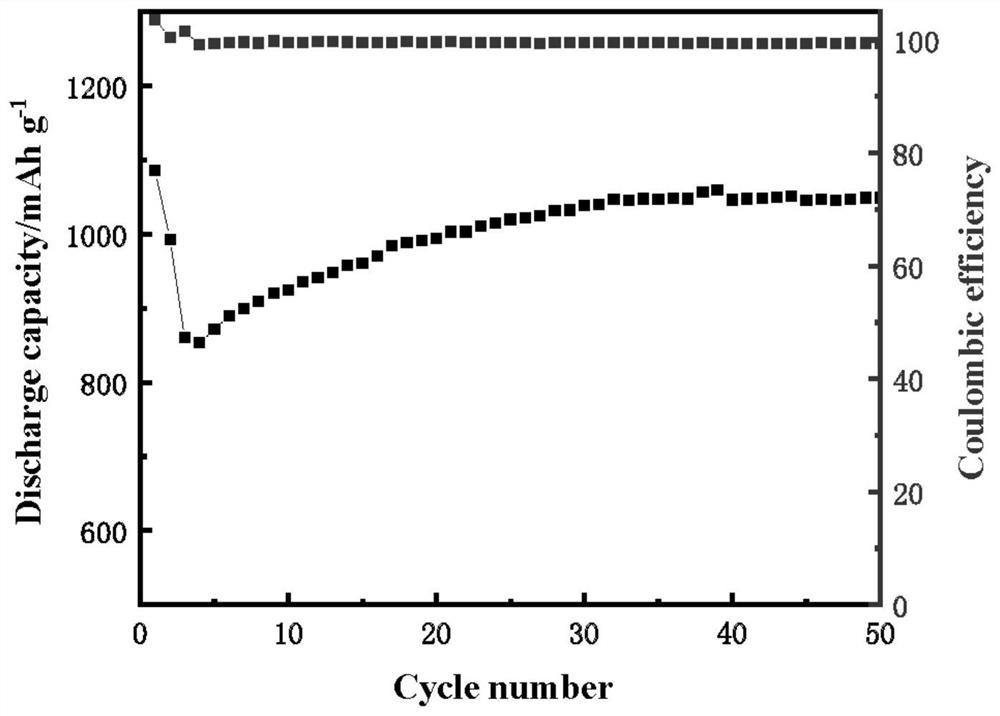

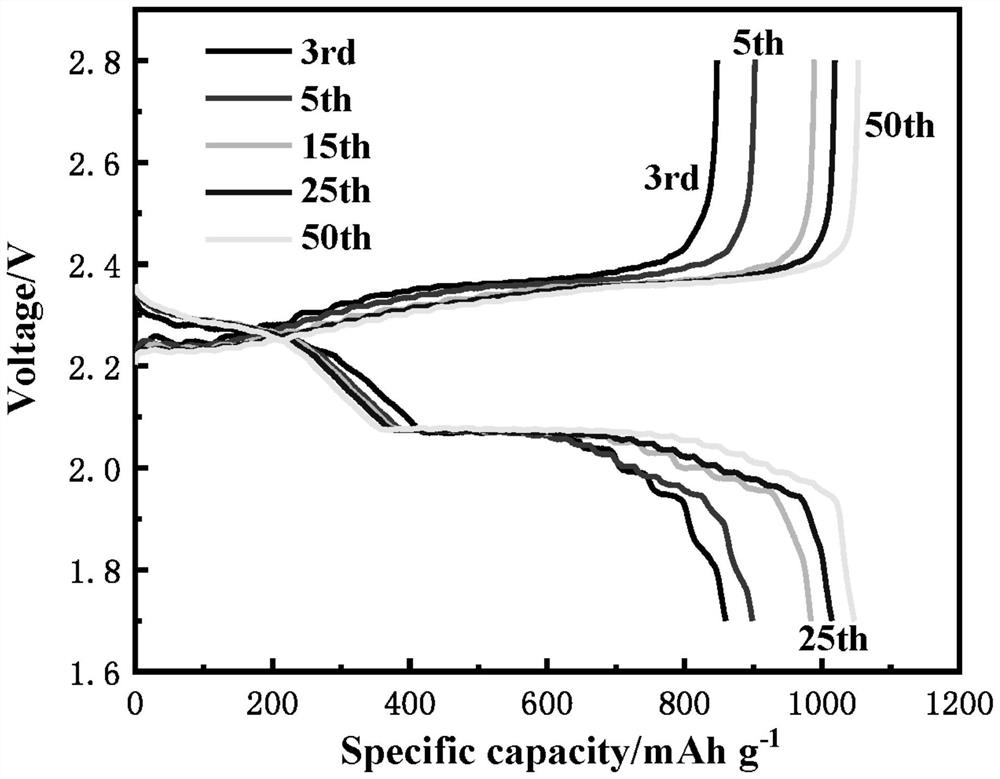

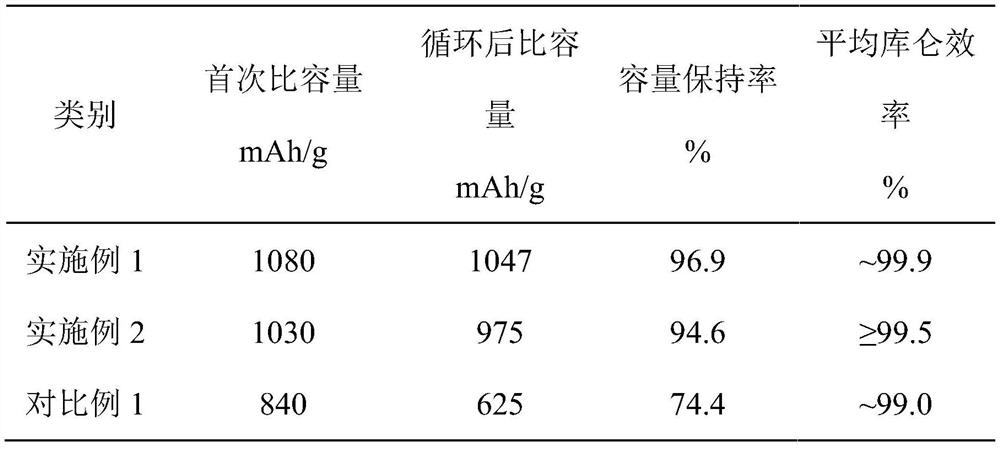

Embodiment 1

[0055] After mixing elemental sulfur and lithium sulfide in DMA with a molar ratio of 5:1, add appropriate amount of LiTFSI and LiNO 3 , made containing Li 2 S 6 electrolyte, Li 2 S 6 The concentration is 80% of its saturation solubility in DMA.

[0056] Stir PEDOT / PSS, P(AM-co-AA), and PEO in NMP / deionized water mixed solvent, coat on carbon fiber cloth, and dry to obtain a polymer with a thickness of 80um (deducting the thickness of carbon fiber cloth) skeleton. Li will be prepared 2 S 6 The electrolyte solution is injected into the polymer framework, and the gel-state positive electrode is obtained after sufficient swelling.

[0057] The above-mentioned condensed positive electrode, porous diaphragm, and lithium sheet are sequentially stacked, and sealed in a button case to assemble a lithium-sulfur battery.

Embodiment 2

[0059] After mixing elemental sulfur and lithium sulfide in DMSO at a molar ratio of 7:1, and then adding an appropriate amount of LiFSI, a Li-containing 2 S 8 electrolyte, Li 2 S 8 The concentration is 95% of its saturation solubility in DMSO.

[0060] Stir PPy and PVDF-HFP in DMF / deionized water mixed solvent, coat on the surface of carbon paper, and dry to obtain a polymer skeleton with a thickness of 200um (deducting the thickness of carbon paper). Soak the polymer backbone in Li 2 S 8 In the electrolyte, a gel-state positive electrode is obtained after being fully swollen.

[0061] The above-mentioned condensed positive electrode, porous diaphragm, and lithium sheet are sequentially stacked, and sealed in a button case to assemble a lithium-sulfur battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com