Anthocyanin nanoparticles based on marine polysaccharide carrier and its preparation method and application in targeted delivery

A nanotechnology of marine polysaccharides and glycosides, applied in the field of nanometers, can solve the problems of loss of functional active ingredients and poor stability of lingonberry anthocyanins, etc., and achieve improved retention rate, good photostability, biocompatibility, and strong stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

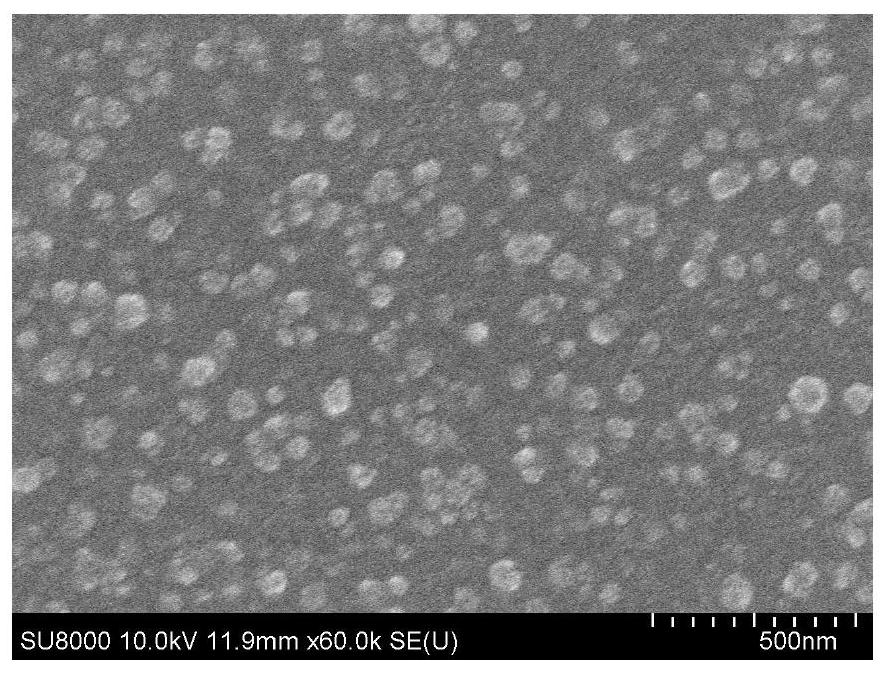

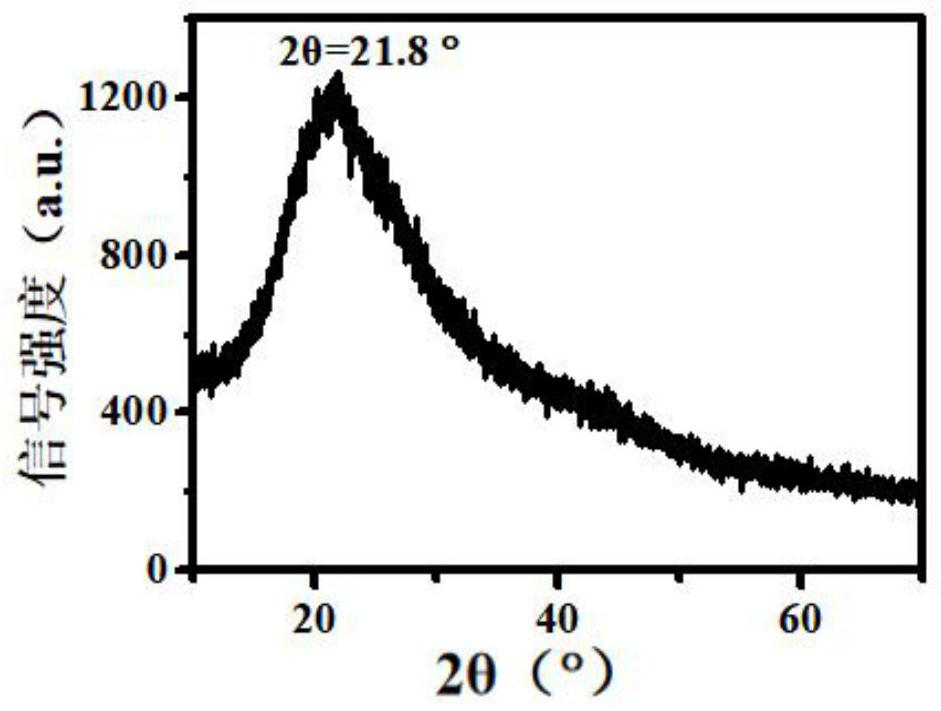

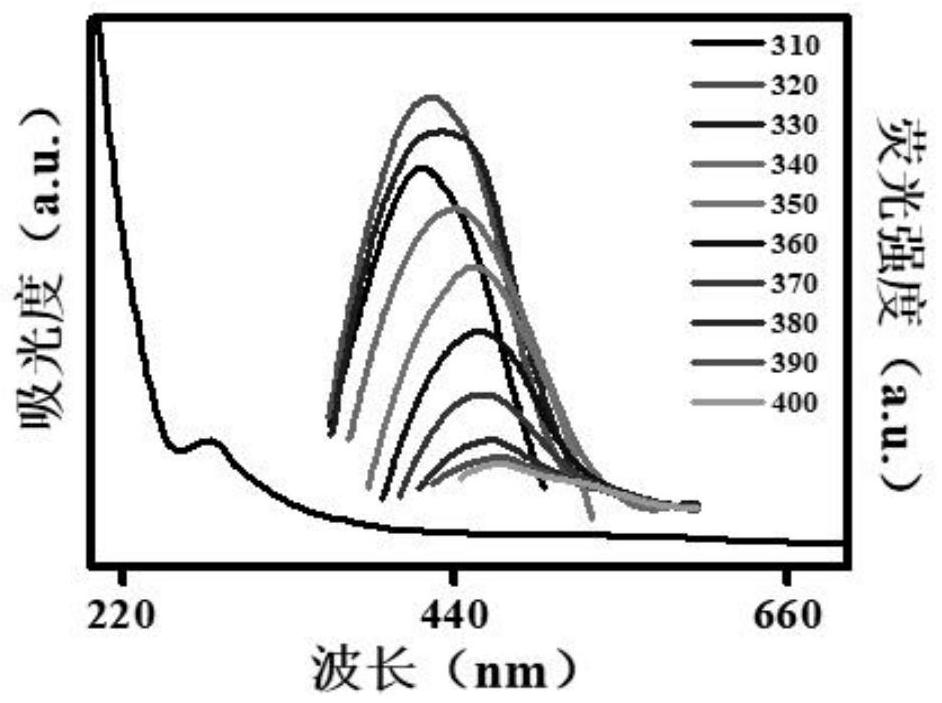

[0039] 1. Preparation of anthocyanin nanoparticles

[0040] S1. Dissolve 5-30 mg of sodium alginate in pH 4.75-6 phosphate buffered saline, add 35-70 mg of EDC and 25-50 mg of HOBt in sequence, and perform magnetic stirring at room temperature at a stirring speed of 500-800 r / min After 60-80 minutes, add 1-5 mg of the food-derived fluorescent nanoparticles, perform magnetic stirring at room temperature at a stirring speed of 500-800 r / min for 24-30 hours, then dialyze with deionized water for 24-72 hours and freeze-dry , to obtain the fluorescent-alginic acid complex;

[0041] S2. Hyaluronic acid can be further conjugated to the backbone of alginate through esterification, using diisopropylcarbodiimide (DIC) as a coupling agent and dimethylaminopyridine (DMAP) as a catalyst. Eliminate the water produced during the chemical reaction. Add 40-60 mg of the fluorescent-alginic acid complex to 4-6 ml of a mixture of DMF and DCM with a volume ratio of 1:1-1.5, add 8-16 mg of DIC an...

Embodiment 1

[0047] Embodiment 1: Preparation of anthocyanin nanoparticles

[0048] S1: Marine polysaccharide sodium alginate (30 mg) was dissolved in phosphate buffered saline (pH 4.75), and EDC (35 mg) and HOBt (25 mg) were added in sequence. After stirring at room temperature for 1 h, food-derived fluorescent nanoparticles (5 mg) were added and stirred for 24 h. Afterwards, the product was dialyzed against deionized water for 24 hours and freeze-dried to obtain a fluorescent-alginic acid complex.

[0049] S2: 40 mg of the fluorescent-alginic acid complex prepared in step S1 was added to 4 ml of a mixture of dimethylformamide DMF and DCM mixed at a volume ratio of 1:1. Subsequently, DIC (8.1 mg) and DMAP (25 mg) were added thereto. The reaction mixture was allowed to stir gently at room temperature for 1 h to activate the carboxyl group of alginic acid.

[0050] S3. Slowly add 1 mg anthocyanin and 8 mg hyaluronic acid to the mixture prepared in S2, and the reaction is further carried ...

Embodiment 2

[0052] Embodiment 2: Preparation of food-borne fluorescent nanoparticles

[0053] Cut 1kg of pork belly evenly into 1×1×1cm 3 Bake the small pieces at 280°C for 30 minutes, soak the baked meat in 3L of absolute ethanol, and keep stirring for 12 hours, select the soluble part filtered by three layers of filter paper and use a rotary evaporator to remove the ethanol , then redissolve the treated soluble part with chloroform: water=3:1 configuration solution, add chloroform to extract and degrease repeatedly until the oil phase is clear, and select the clear water phase part to pass through D101 macroporous adsorption resin column For chromatography, the fluorescent part was pre-cooled at -80°C for 2h, and then freeze-dried at -50°C under a vacuum of 40Pa for 48h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com