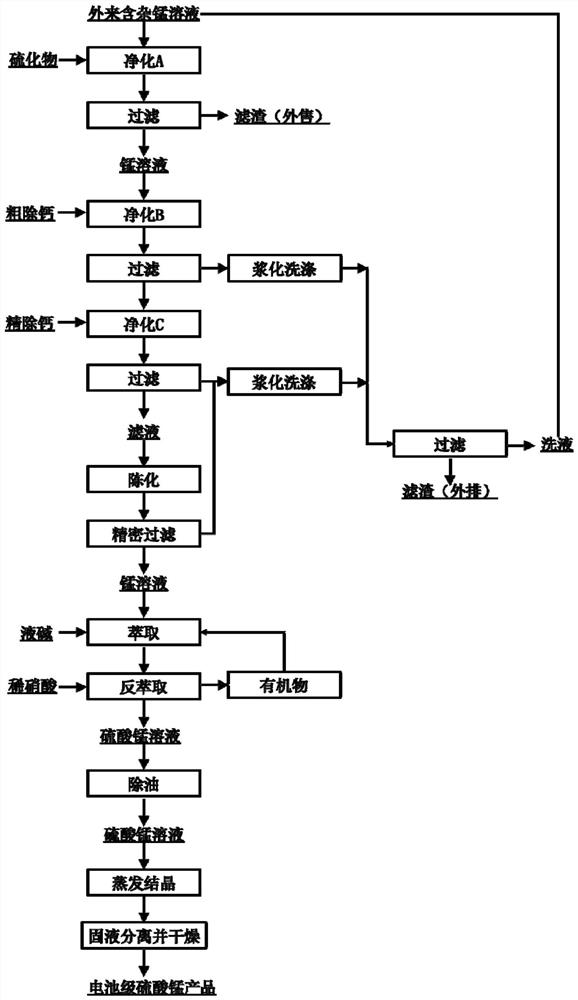

Method for preparing aluminum-doped battery-grade hydroxyl manganese oxide by utilizing waste manganese liquid

A manganese oxyhydroxide, battery-level technology, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of long operation time, poor production efficiency, high production cost, etc., achieve the reduction of heavy metal impurity ions, solve the problem of excessive reagent residue, production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

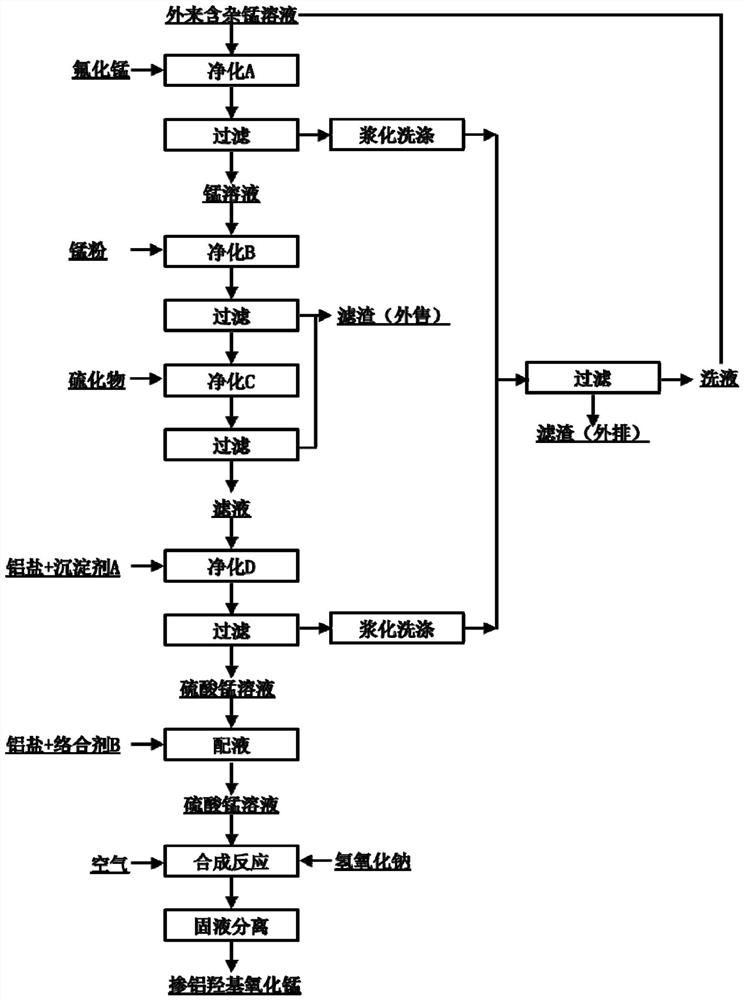

[0053] Embodiment 1 of the present invention is: a method for preparing aluminum-doped battery-grade manganese oxyhydroxide by using waste manganese liquid, such as image 3 shown, including the following steps:

[0054] S1. Decalcification by precipitation (purification A):

[0055]Add the waste manganese liquid into the reaction kettle, start stirring, control the temperature at 85°C, adjust the pH value of the solution to 5.3, add manganese fluoride precipitant to make the Ca element concentration in the solution reach the specified value (0.005g / L), continue The reaction is not less than 2 hours, filtered and separated, the filtrate is aged for 24 hours, and the aged liquid is finely filtered to obtain a crude manganese solution;

[0056] S2. Manganese replacement precipitation (purification B):

[0057] Add the crude manganese solution into the reaction kettle, start stirring, heat to 60°C, adjust the pH of the solution to 1.8, gradually add manganese powder to make the...

Embodiment 2

[0073] Embodiment 2 of the present invention is: a method for preparing aluminum-doped battery-grade manganese oxyhydroxide by using waste manganese liquid, such as image 3 shown, including the following steps:

[0074] S1. Decalcification by precipitation (purification A):

[0075] Add the waste manganese solution into the reaction kettle, start stirring, control the temperature at 83°C, adjust the pH value of the solution to 5.3, add manganese fluoride precipitant to make the Ca element in the solution reach the specified value (0.005g / L), continue React for 2 hours, filter and separate, age the filtrate for 24 hours, fine filter the aged solution to obtain a crude manganese solution;

[0076] S2. Manganese replacement precipitation (purification B):

[0077] Add the crude manganese solution into the reaction kettle, start stirring, heat to 60°C, adjust the pH of the solution to 1.8, gradually add manganese powder to make the Cu element in the solution reach the specified...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap