Isophthalonitrile wastewater treatment system

A wastewater treatment system, isophthalonitrile technology, applied in the direction of water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., can solve the problem of difficulty in meeting wastewater treatment requirements, increasing the concentration of ammonia nitrogen in wastewater, and affecting microorganisms Reactive and other issues, to achieve the effect of three-dimensional electrolytic reduction treatment, improve treatment efficiency, and oxygen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

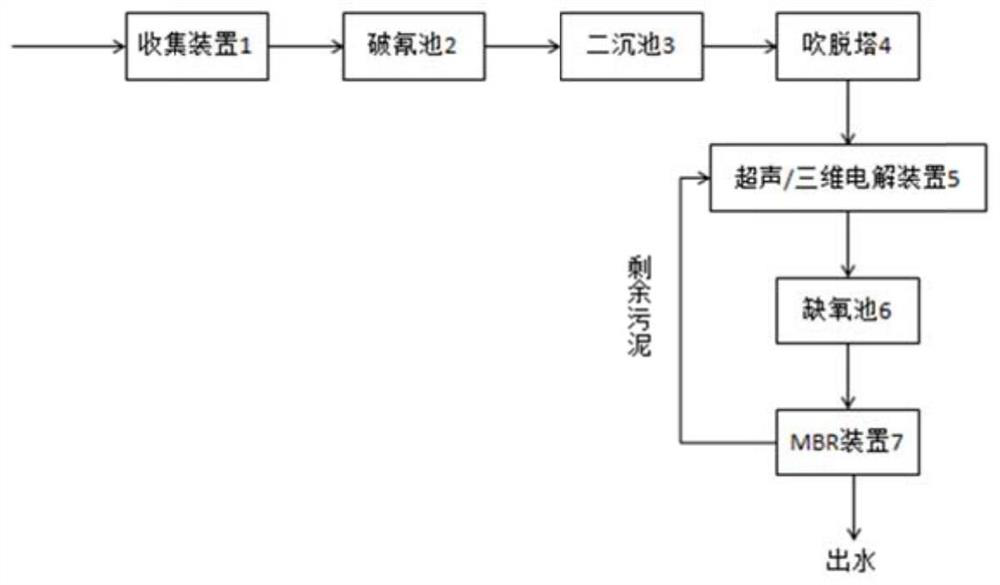

[0032] Such as figure 1 As shown, the raw water quality of isophthalonitrile wastewater treated by this system is: COD is 9800mg / L, BOD is 2980mg / L, TN is 985mg / L, NH 4 + -H is 9050mg / L, CN- is 1780mg / L;

[0033] The isophthalonitrile wastewater is introduced into the collecting device 1 for homogeneous treatment, and the homogeneous wastewater is introduced into the cyanide removal pool 2, and the pH in the cyanide removal pool 2 is adjusted by the pH regulator to be 6.3- 6.5, then the CN in the cyanide removal pool 2 is obtained by the dosage of the sodium ferric sulfate - content of 2 times, after the addition is complete, start the fast stirring mode of the agitator, the speed is 350r / min, after 30min of rapid stirring, start the slow stirring mode of the agitator, the speed is 100r / min, the slow stirring mode 10min, after the end of the slow stirring mode, the calcium hydroxide doser will add calcium hydroxide, the end point of the addition is pH to 7.5, and after 5-10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com