Antifouling coating composition, antifouling coating film, substrate with antifouling coating film, manufacturing method thereof, and repairing method

A technology of antifouling coatings and compositions, applied in antifouling/underwater coatings, chemical instruments and methods, devices for coating liquids on surfaces, etc., which can solve the problems of reduced flow rate, hypoxia-induced death of cultured organisms and fished organisms, Water supply and drainage pipe blockage and other problems, to achieve the effect of excellent aesthetics and excellent long-term antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

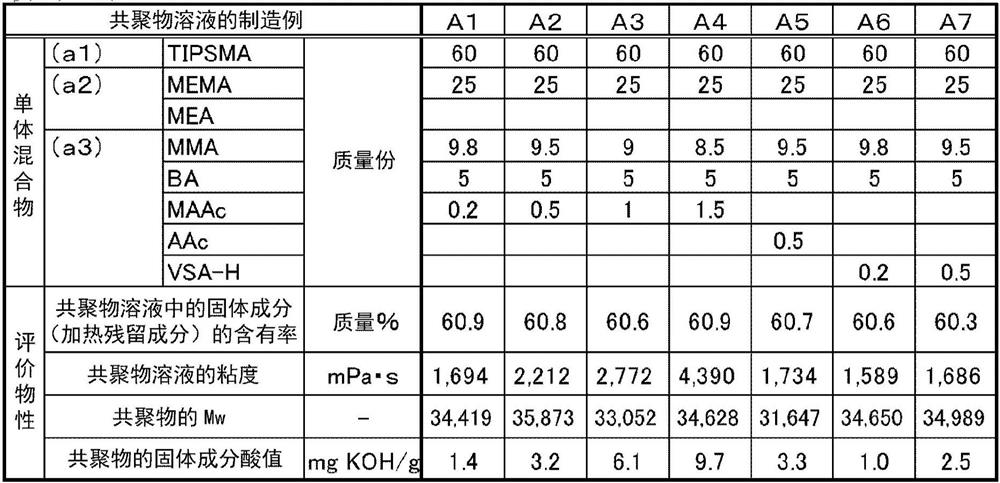

[0236] Hereinafter, the present invention will be further specifically described by way of examples, but the present invention is not limited by the examples at all. Hereinafter, "part" means a mass part unless it violates the gist in particular. The evaluation of the copolymer, the antifouling coating composition, the antifouling coating film, and the like, which will be described later, was performed as follows.

[0237] [Analysis method of copolymer]

[0238]

[0239] Measure the copolymer solution into a metal test dish of known mass, spread it on the bottom, put it in a constant temperature bath maintained at a temperature of 105-110°C for 3 hours, take it out and cool it to room temperature, weigh the mass again, and find Take out the remaining amount in the metal test dish. The content rate (mass %) of the solid content was calculated by the following formula.

[0240] Content ratio of solid content (mass %)=remainder in metal test dish (g)×100 / mass (g) of measured...

manufacture example A1

[0337] The reaction was carried out under normal pressure and nitrogen atmosphere. 428.6 parts of xylene and 100 parts of triisopropylsilyl methacrylate (TIPSMA) were added to a reaction vessel equipped with a stirrer, a reflux condenser, a thermometer, a nitrogen introduction tube, and a dropping funnel, and stirred with a stirrer. It was heated until the liquid temperature reached 80°C. While maintaining the liquid temperature in the reaction container at 80±5°C, using a dropping funnel, 500 parts of TIPSMA and 2-methoxyethyl methacrylate (MEMA) were added dropwise to the reaction container over 2 hours. 250 parts, 98 parts of methyl methacrylate (MMA), 50 parts of butyl acrylate (BA), 2 parts of methacrylic acid (MAAc) and 13 parts of 2,2'-azobisisobutyronitrile (AIBN) mixture. After completion of the dropwise addition, the reaction solution was stirred at 80° C. for 1 hour, and then stirred at 80 to 95° C. for 1 hour and 30 minutes. Then, 1 part of AIBN was added to the...

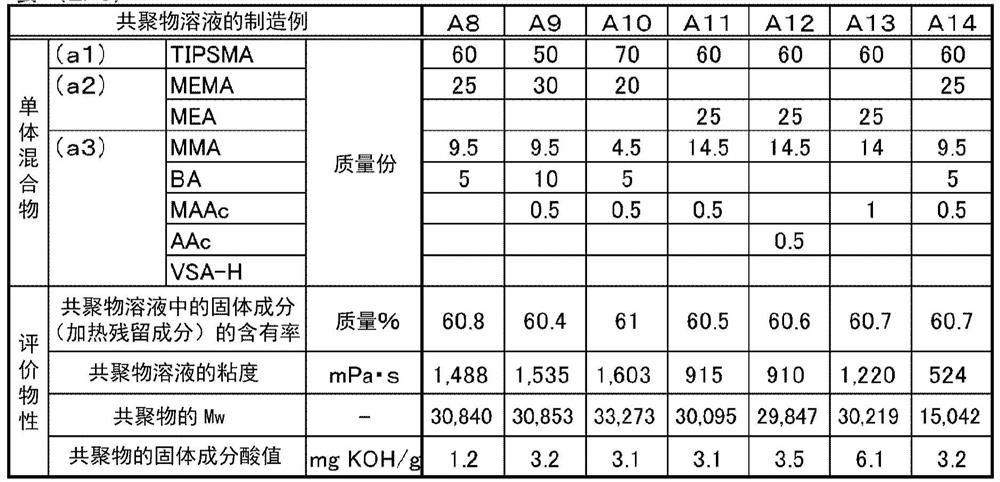

manufacture example A9

[0343] The reaction was carried out under normal pressure and nitrogen atmosphere. 538.5 parts of xylenes were put into a reaction container equipped with a stirrer, a reflux condenser, a thermometer, a nitrogen introduction tube, and a dropping funnel, and the liquid temperature was heated to 80° C. while stirring with a stirrer. While maintaining the liquid temperature in the reaction vessel at 80±5°C, using a dropping funnel, drip 500 parts of TIPSMA, 300 parts of MEMA, 95 parts of MMA, and 100 parts of BA into the reaction vessel over 2 hours. , a mixture of 5 parts of MAAc and 13 parts of AIBN. After completion of the dropwise addition, the reaction solution was stirred at 80° C. for 1 hour, and then stirred at 80 to 95° C. for 1 hour and 30 minutes. Then, 1 part of AIBN was added to the reaction liquid every 30 minutes while maintaining the temperature at 95° C. 4 times, the liquid temperature was raised to 105° C., and the polymerization reaction was completed. Next, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com