Directional fibrin and polypeptide interpenetrating network composite hydrogel for nerve regeneration and preparation method thereof

A composite hydrogel and fibrin technology, applied in the field of oriented fibrin and polypeptide interpenetrating network composite hydrogel and its preparation, can solve the problems of short half-life, fast diffusion, etc., to promote angiogenesis and nerve cell adhesion , to avoid unpredictable and unnecessary physiological or pathological effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

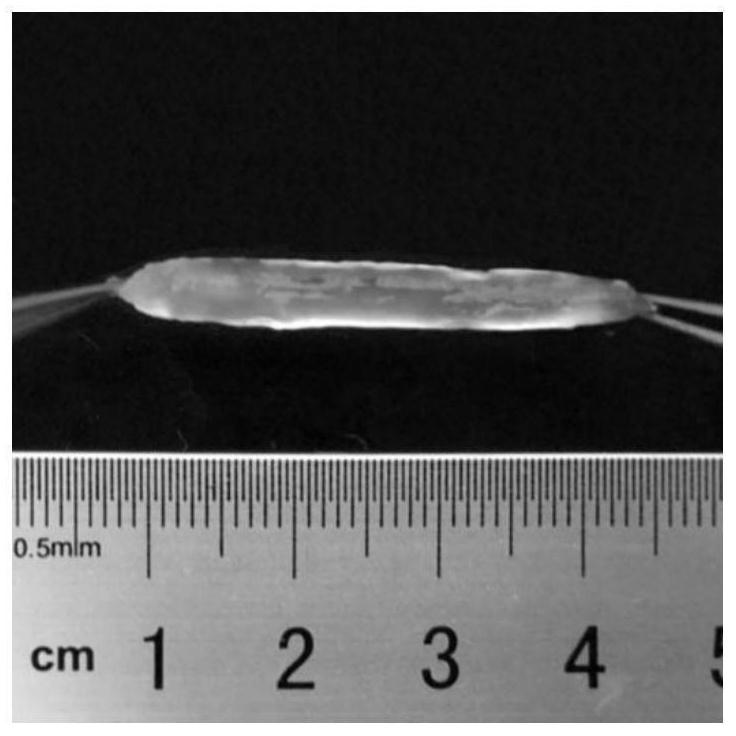

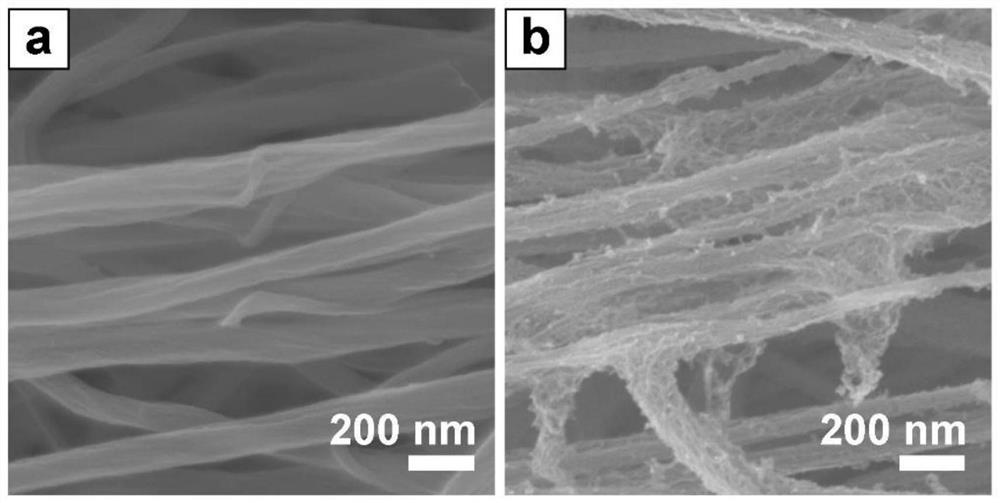

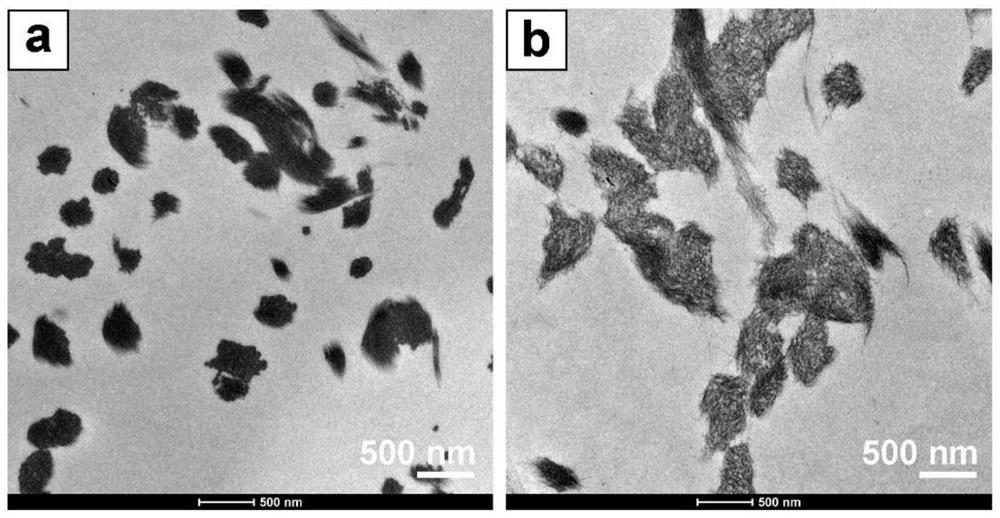

[0048] The preparation method of the oriented fibrin and functional polypeptide interpenetrating network composite hydrogel for nerve regeneration of the present invention comprises:

[0049] 1) Dissolving fibrinogen in pure water and mixing it evenly with polyethylene oxide aqueous solution to obtain an electrospinning stock solution, the mass fraction of fibrinogen in the electrospinning stock solution is 2%-8%, and the mass fraction of polyethylene oxide is 0.1%-0.8%, the electrospinning stock solution is injected into the syringe for use;

[0050] 2) Add CaCl 2 Mix the aqueous solution with the thrombin solution to obtain a cross-linking solution and keep it warm at 37°C, and the CaCl in the cross-linking solution 2 The mass fraction of thrombin is 0.5%-3%, the content of thrombin is 4-50Units / mL, and the cross-linking solution is placed in a metal rotating receiving tray for use;

[0051] 3) The electrospinning stock solution injected into the syringe is electrospun und...

Embodiment 1

[0062] 1) Dissolving fibrinogen in pure water and mixing it evenly with polyethylene oxide aqueous solution to obtain electrospinning stock solution. The mass fraction of fibrin in the electrospinning stock solution is 2%, and the mass fraction of polyethylene oxide is 0.5%. The electrospinning stock solution was then injected into a syringe for use.

[0063] 2) Add CaCl 2 The aqueous solution was mixed with the thrombin solution to obtain a cross-linking solution, which was then kept at 37°C for use. CaCl in the crosslinking solution 2The mass fraction of the thrombin is 0.5%, and the thrombin content is 4Units / mL. The cross-linking solution was then placed in a metal rotating receiving pan for use.

[0064] 3) The electrospinning stock solution injected into the syringe is electrospun under the action of the propulsion pump, the injection speed of the fibrinogen solution is adjusted to 2mL / h, and the loading voltage is 4kV to obtain continuous and stable fibrinogen spinn...

Embodiment 2

[0069] 1) Dissolving fibrinogen in pure water and mixing it evenly with polyethylene oxide aqueous solution to obtain electrospinning stock solution. The mass fraction of fibrin in the electrospinning stock solution is 2%, and the mass fraction of polyethylene oxide is 0.5%. The electrospinning stock solution was then injected into a syringe for use.

[0070] 2) Add CaCl 2 The aqueous solution was mixed with the thrombin solution to obtain a cross-linking solution, which was then kept at 37°C for use. CaCl in the crosslinking solution 2 The mass fraction of the thrombin is 0.5%, and the thrombin content is 4Units / mL. The cross-linking solution was then placed in a metal rotating receiving pan for use.

[0071] 3) The electrospinning stock solution injected into the syringe is electrospun under the action of the propulsion pump, the injection speed of the fibrinogen solution is adjusted to 2mL / h, and the loading voltage is 4kV to obtain continuous and stable fibrinogen spin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com