A solid acid and its preparation method, a solid acid-loaded microchannel reactor and its preparation method, and a method for preparing hydroxycitronellal

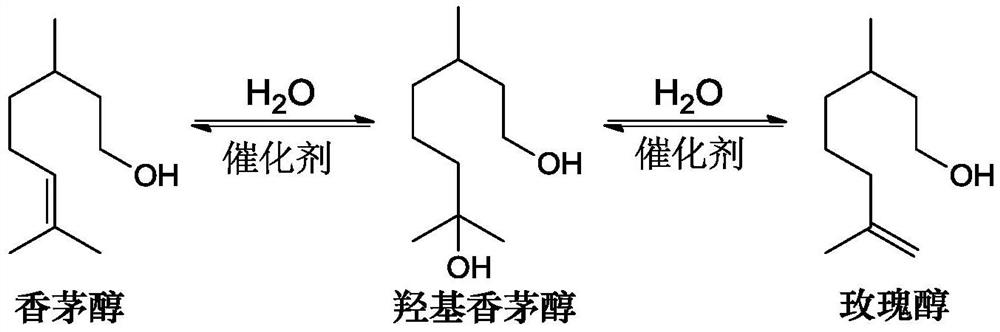

A technology of a microchannel reactor and a solid acid is applied in the field of preparing hydroxycitronellol by hydration reaction of citronellol, which can solve the problems of difficult recovery of catalyst, low reaction conversion rate and yield, influence on product aroma quality, etc. Continuity and operability, improve selectivity, reduce the effect of corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

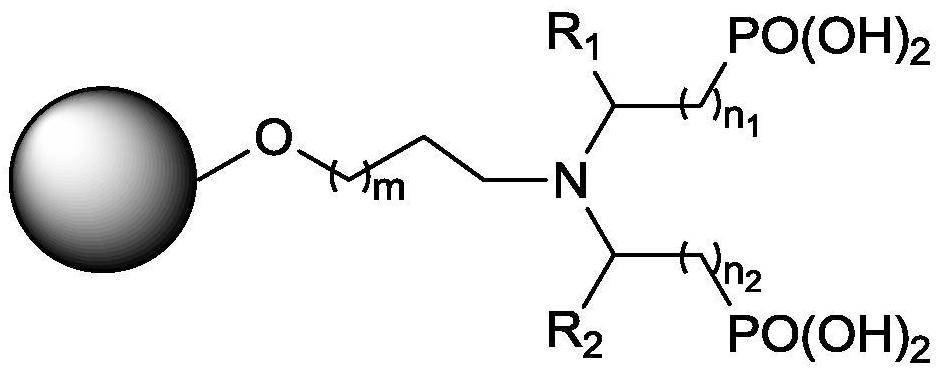

Method used

Image

Examples

Embodiment 1

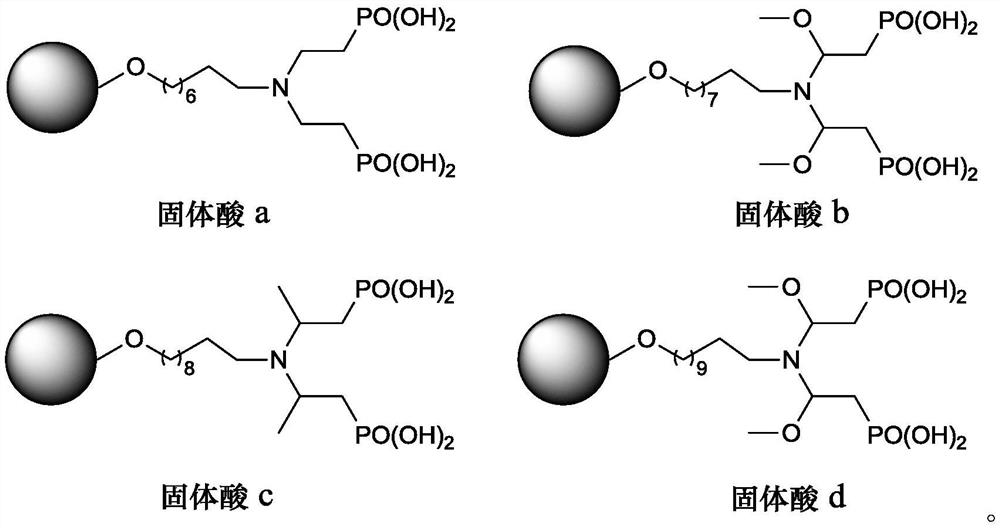

[0066] Preparation of solid acid a:

[0067] Chloromethylated polystyrene resin (CAS: 55844-94-5), 8-aminooctanol, 2-chloroethyl phosphoric acid, toluene, 30wt% sodium hydroxide solution according to 1:1.5:3.5:10:25 After mixing the mass proportions, reflux and stir for 1 hour, lower the temperature to 50°C, adjust the pH to about 6 with 2N hydrochloric acid solution, cool to room temperature, filter with suction, wash with deionized water until there are no chloride ions, and dry at 50°C to obtain solid acid a.

[0068] 1H NMR (300MHz, Chloroform-d) δ7.63(s,4H),7.35–7.11(m,81H),3.58–3.51(m,2H),3.51–3.43(m,2H),3.03(d,J =1.1Hz,1H),2.91–2.82(m,4H),2.81(t,J=1.0Hz,11H),2.78–2.67(m,5H),2.54(d,J=2.7Hz,2H),2.09 –1.83(m,33H),1.77(d,J=12.4Hz,1H),1.59–1.48(m,4H),1.32(dd,J=11.6,7.2Hz,8H)

[0069] The preparation of the microchannel reactor of loading solid acid a:

[0070] Solid acid a (10g), ethanol (300ml) and 0.005mol / L hydrochloric acid aqueous solution (150ml) were ultrasonicall...

Embodiment 2-4

[0074] Preparation of solid acids b-d:

[0075] The preparation formula of table 1 solid acid b-d

[0076]

[0077] The preparation of solid acid b-d was carried out according to the formula in Table 1 and the operation steps of Example 1.

[0078] Microchannel reactor loaded with solid acid and preparation of hydroxycitronellol:

[0079] Carry out the preparation of loaded microchannel reactor and the preparation of hydroxycitronellol according to the step of embodiment 1, corresponding preparation parameter and reaction result are as shown in table 2 and 3, no by-product rhodamine is produced.

[0080] Table 2 Loaded Microchannel Reactor Preparation Conditions

[0081]

[0082] Table 3 Hydration reaction conditions and results

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com