Method for producing high-purity colorless transparent polyaluminum chloride by using aluminum ash

A polyaluminum chloride and aluminum ash technology, applied in aluminum chloride, aluminum halide and other directions, can solve the problems of high quality requirements of raw and auxiliary materials, no method for removing impurities such as iron and calcium, and high cost, so as to improve operational safety. , the effect of improving flexibility and expanding the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

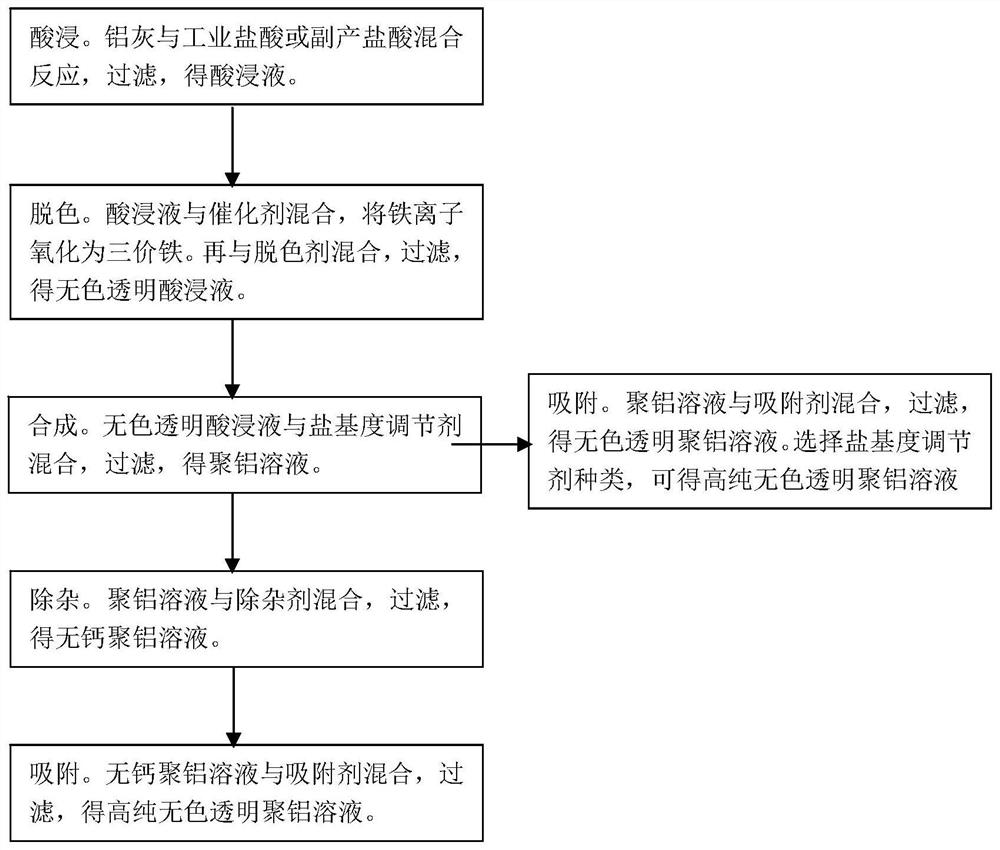

Method used

Image

Examples

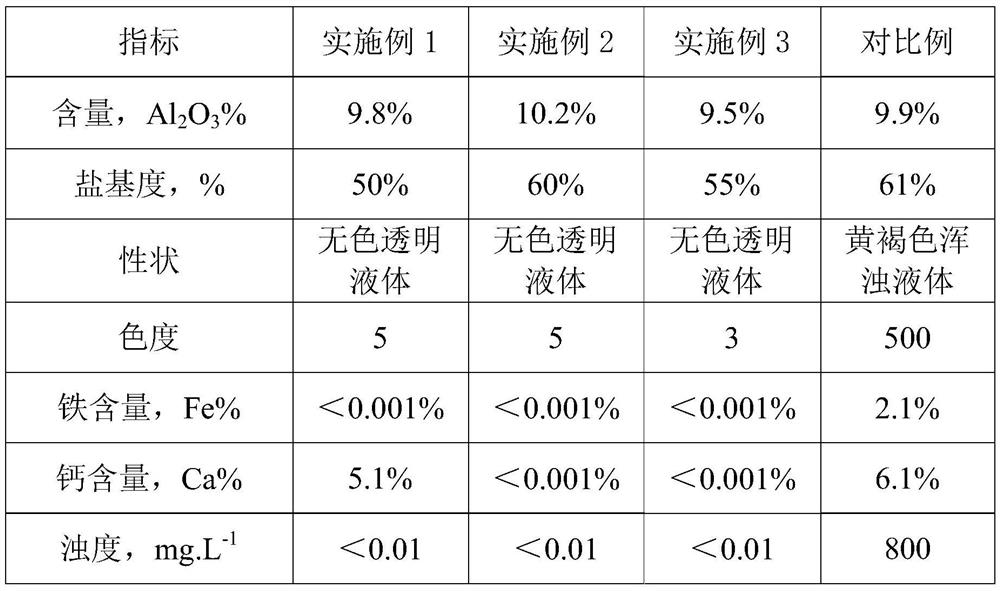

Embodiment 1

[0036] (1) Add 15 tons of by-product hydrochloric acid (20-30% hydrogen chloride content) into the acid leaching reactor, slowly add 5 tons of aluminum ash, and the feeding time is 3 hours. After feeding, the reaction was continued for 1 hour at a reaction temperature of 50°C. The mixed material is pumped into the underflow plate frame for solid-liquid separation. The separated liquid is a mixed solution of impurities such as aluminum trichloride, hydrogen chloride, water and iron, 17 tons.

[0037] (2) Add 17 tons of pickling liquid into the decolorization reaction kettle, add 0.01 tons of sodium chlorate, and stir for 1 hour. Then add 0.02 tons of waste aluminum chips, and stir for 1 hour. Filter through plate and frame to obtain 16.5 tons of colorless and transparent acid dipping solution.

[0038] (3) Add 16.5 tons of colorless and transparent acid immersion solution into the synthesis reaction kettle, heat it with steam to 60°C, then slowly add 1.4 tons of calcium oxid...

Embodiment 2

[0041] (1) Add 20 tons of industrial hydrochloric acid to the acid leaching reactor, slowly add 6.5 tons of aluminum ash, and the feeding time is 4.5 hours. After feeding, the reaction was continued for 2 hours, and the reaction temperature was 60°C. The mixed material is pumped into the underflow plate frame for solid-liquid separation. The separated liquid is a mixed solution of impurities such as aluminum trichloride, hydrogen chloride, water and iron, 23.5 tons.

[0042] (2) Add 23.5 tons of pickling solution into the decolorization reaction kettle, add 0.07 tons of sodium hypochlorite, and stir for 2 hours. Then add 0.05 tons of waste aluminum, and stir for 2 hours. Through plate and frame filtration, 23 tons of colorless and transparent acid dipping solution were obtained.

[0043] (3) Add 23 tons of colorless and transparent acid dipping solution into the synthesis reaction kettle, heat it with steam to 80° C., then slowly add 4 tons of calcium carbonate for 4 hours, s...

Embodiment 3

[0046] (1) Add 10 tons of industrial hydrochloric acid to the acid leaching reactor, slowly add 3.5 tons of aluminum ash, and the feeding time is 2.5 hours. After feeding, the reaction was continued for 1 hour at a reaction temperature of 70°C. The mixed material is pumped into the underflow plate frame for solid-liquid separation. The separated liquid is 12 tons of mixed solution of impurities such as aluminum trichloride, hydrogen chloride, water and iron.

[0047] (2) Add 12 tons of pickling solution into the decolorization reaction kettle, add 0.08 tons of hydrogen peroxide, and stir for 3 hours. Then add 0.02 tons of metal aluminum powder, and stir for 3 hours. Filter through plate and frame to obtain 11.5 tons of colorless and transparent acid dipping solution.

[0048] (3) Add 11.5 tons of colorless and transparent acid immersion solution into the synthesis reaction kettle, heat it with steam to 80°C, then slowly add 1.8 tons of sodium carbonate for 3 hours, and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com