Gasified grey water aeration hardness removal device, treatment method and application

An aeration and gray water technology, applied in water/sewage treatment, chemical instruments and methods, neutralized water/sewage treatment, etc., can solve the problems of large lye consumption, short service life of resin and membrane, and carbon dioxide dosage Large and other problems, to achieve the effect of uniform particle size and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

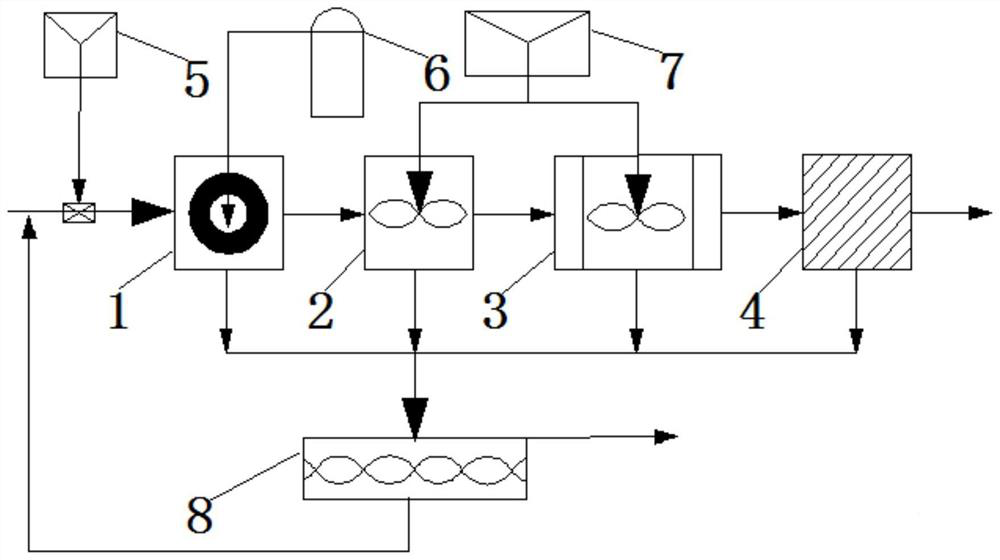

[0078] This embodiment provides a device for aeration and dehardening of gasified gray water, and the structural diagram of the device is as follows: figure 1 As shown, it includes a carbon dioxide aeration unit 1 , a flocculation settling unit and a sedimentation separation unit 4 connected in sequence, and the carbon dioxide aeration unit 1 includes a cyclone aeration component.

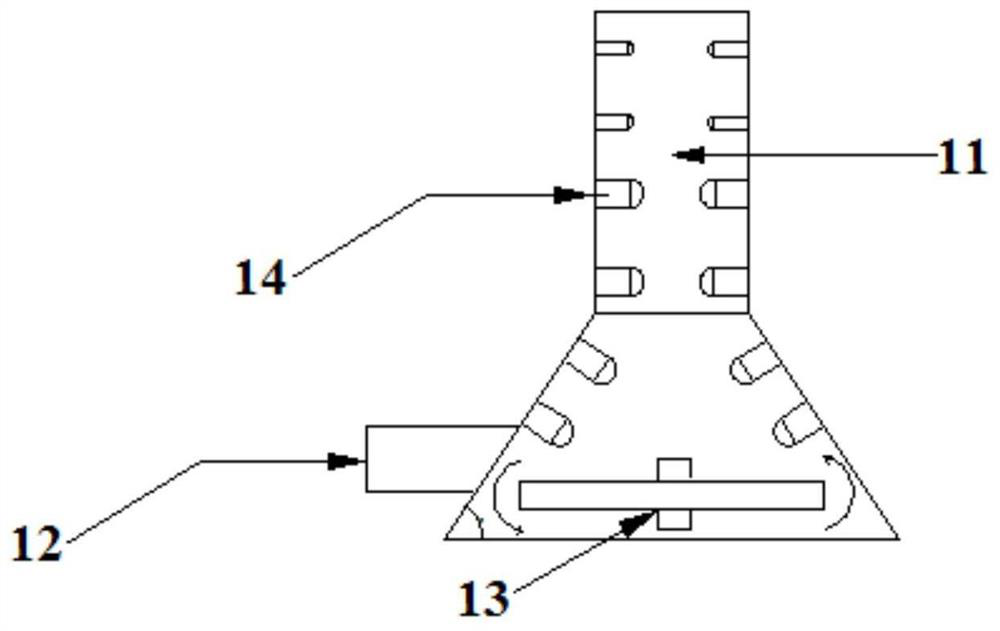

[0079] The structural schematic diagram of the cyclone aeration assembly is as follows: figure 2 As shown, it includes an aeration chamber 11, an air inlet pipe 12, an air distribution pipe 13 and a cutter 14. The air inlet pipe 12 is connected to the air distribution pipe 13, and the air distribution pipe 13 is located at the bottom of the cyclone aeration assembly. The cutter 14 is arranged on the inner wall of the aeration chamber 11.

[0080] The air distribution pipe 13 includes a horizontal air distribution pipe and a longitudinal air distribution pipe.

[0081] There are three cyclone aer...

Embodiment 2

[0093] This embodiment provides an aeration and dehardening device for gasified gray water. The device includes a carbon dioxide aeration unit 1, a flocculation settling unit and a sedimentation separation unit 4 connected in sequence. The carbon dioxide aeration unit 1 includes a cyclone aeration unit. gas components.

[0094] The cyclone aeration assembly includes an aeration chamber 11, an air inlet pipe 12, an air distribution pipe 13 and a cutter 14, the air inlet pipe 12 is connected to the air distribution pipe 13, and the air distribution pipe 13 is located at the bottom of the cyclone aeration assembly, The cutter 14 is arranged on the inner wall of the aeration chamber 11 .

[0095] The air distribution pipe 13 includes a horizontal air distribution pipe and a longitudinal air distribution pipe.

[0096] There are two swirl aeration components, and the material is EPDM.

[0097] The aeration chamber 11 is trumpet-shaped as a whole, and the air distribution pipe 13 ...

Embodiment 3

[0107] This embodiment provides a method for aeration and dehardening of gasification gray water. The method is carried out using the device in Example 1, wherein the gasification gray water is aerospace furnace pulverized coal gasification gray water, and the total hardness is 1550mg / L, suspended matter content 120mg / L, turbidity 56NTU, water temperature 80℃;

[0108] The method comprises the steps of:

[0109] (1) Set the flow rate to 150m 3 / h of gasified gray water to be treated is mixed with sodium hydroxide solution to adjust the pH to 9, and then carbon dioxide is introduced into the air through the cyclone aeration module for aeration, and the flow rate of carbon dioxide is controlled to be 0.15Nm 3 / m 3 , the pressure is 0.3MPa, and microflocs such as calcium carbonate, magnesium hydroxide, and magnesium carbonate are initially formed;

[0110] (2) the gasification gray water that step (1) generates micro-floc is mixed with flocculant PAM, and the add-on of describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com