Preparation method of lithium-sulfur battery modified diaphragm based on nano metal hydroxide-carbon composite material

A carbon composite material, hydroxide technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as limited control ability, achieve improved cycle life, obvious adsorption, reduce The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing a lithium-sulfur battery diaphragm modified by nanometer metal hydroxide, the lithium-sulfur battery diaphragm includes a diaphragm body, one side of the diaphragm body is coated with a modified coating, and the modified coating It contains nickel hydroxide powder, conductive agent SP and binder PVDF; the mass ratio of nickel hydroxide powder, conductive agent SP and binder PVDF is 8:1:1;

[0051] The preparation method steps are as follows:

[0052] (1) Take by weighing 0.24g sodium hydroxide, dissolve sodium hydroxide in 500mL deionized water, the concentration is 0.012mol / L, weigh 0.548g nickel nitrate, put it into a beaker filled with 100mL deionized water, stir until Completely dissolve, gradually add 0.012mol / L sodium hydroxide solution dropwise to the slowly stirring nickel nitrate solution, the reaction finally produces a light green precipitate, collect the precipitate, wash it with deionized water several times, and dry it at 60°C. Obta...

Embodiment 2

[0060] A method for preparing a lithium-sulfur battery diaphragm modified by nanometer metal hydroxide, the lithium-sulfur battery diaphragm includes a diaphragm body, one side of the diaphragm body is coated with a modified coating, and the modified coating It contains nano-nickel hydroxide-graphene composite powder, conductive agent SP and binder PVDF; the mass ratio of nano-nickel hydroxide-graphene composite powder, conductive agent SP and binder PVDF is 8:1: 1;

[0061] The preparation method steps are as follows:

[0062] (1) Measure 8ml of graphene oxide solution with a solid content of 5mg / ml, weigh 1.6g of nickel sulfate hexahydrate and 0.72g of urotropine, put the above materials into a beaker containing 40mL of deionized water, stir After uniformity, the aqueous solution was transferred to the reaction kettle and sealed, and then kept at 95°C for 6 hours to form a black precipitate. The precipitate was collected, washed with deionized water several times, and then ...

Embodiment 3

[0069] A method for preparing a lithium-sulfur battery diaphragm modified by nanometer metal hydroxide, the lithium-sulfur battery diaphragm includes a diaphragm body, one side of the diaphragm body is coated with a modified coating, and the modified coating It contains metal hydroxide composite powder, conductive agent SP and binder PVDF; the mass ratio of nickel hydroxide / manganese hydroxide composite material, conductive agent SP and binder PVDF is 8:1:1;

[0070] The preparation method steps are as follows:

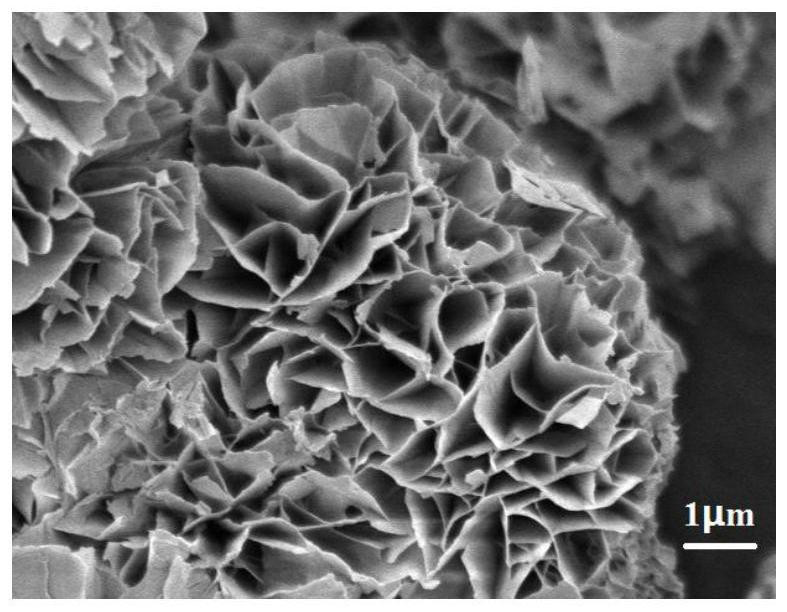

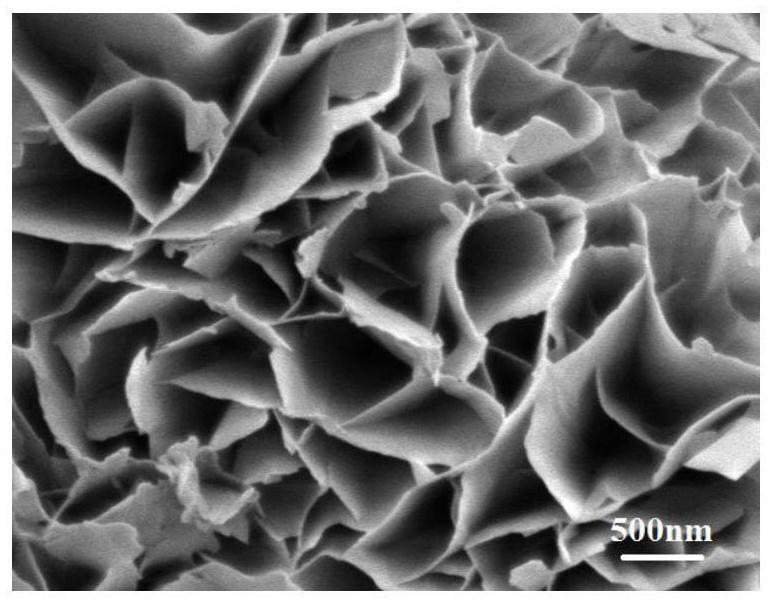

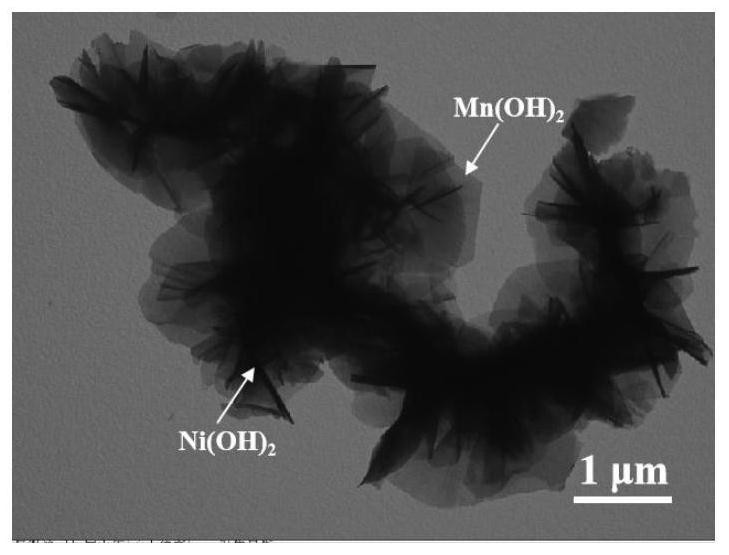

[0071] (1) Weigh 0.570g nickel chloride hexahydrate, 0.119g manganese chloride tetrahydrate, and 0.540g urea, put the three into a beaker filled with 40mL deionized water and stir until completely dissolved, then transfer the aqueous solution to the reaction The kettle was sealed, and then kept at 80°C for 12 hours to produce a black precipitate. The precipitate was collected, washed with deionized water for several times, and then freeze-dried to obtain a nano-nickel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com