A skull repair plate with composite structure

A composite structure and plate technology, which is applied in the fields of polymer materials and biomedical engineering, can solve the problems of large difference in strength and weaken the mechanical strength of PEEK, and achieve the effect of promoting osteogenic differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of spherical porogen: prepare 10g of glutinous rice flour and 2g of water into a paste, add vegetable oil, add 50g of NaCl crystal particles with a particle size of 70 mesh, stir with a stirrer at 1000 rpm for 5 minutes, and heat the oil to 80°C , After the stirring is completed, the spherical sodium chloride particles are then sieved from the oil, washed in isopropanol, dried, and then sieved to obtain spherical sodium chloride with a particle size of 600 μm.

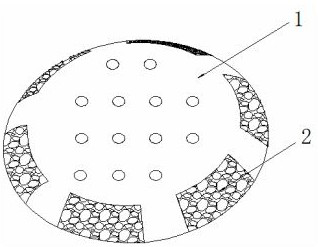

[0029] Preparation of powder: pure polyetheretherketone material is the raw material for the middle solid structure and reinforcing ribs; spherical sodium chloride particles and polyetheretherketone powder are mixed in a ratio of 3:7 as the raw material for the outer ring porous body.

[0030] Molding: The powder pressing molding method is adopted. First, the middle solid part and 6 ribs are pressed into a flat plate, and the porous body powder is filled; then sintered at a temperature of 380 ° C for ...

Embodiment 2

[0034] Preparation of spherical porogen: prepare 10g of glutinous rice flour and 2g of water into a paste, add vegetable oil, add 50g of NaCl crystal particles with a particle size of 70 mesh and 50 mesh, stir with a stirrer at 1000 rpm for 5 minutes, and simultaneously heat the oil to After heating at 80°C and stirring, the spherical sodium chloride particles were then sieved from the oil, washed in isopropanol, dried, and then sieved to obtain spherical sodium chloride with a particle size of 600 μm and 200 μm.

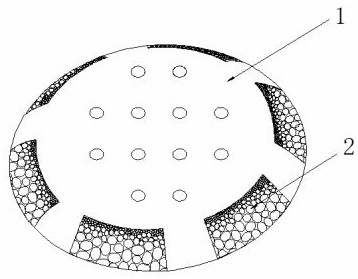

[0035] Preparation of powder: pure polyether ether ketone material is the raw material for the intermediate solid structure and reinforcing ribs; the spherical sodium chloride particles of 600 μm and the spherical sodium chloride particles of 200 μm are respectively mixed with polyether ether ketone powder in a ratio of 3:7 Raw materials for the porous body of the outer ring were mixed.

[0036] Molding: Using powder pressing molding method, the middle solid part an...

Embodiment 3

[0041] Preparation of spherical porogen: prepare 10g of glutinous rice flour and 2g of water into a paste, add vegetable oil, add 50g of NaCl crystal particles with a particle size of 70 mesh, stir with a stirrer at 1000 rpm for 5 minutes, and heat the oil to 80°C , After the stirring is completed, the spherical sodium chloride particles are then sieved from the oil, washed in isopropanol, dried, and then sieved to obtain spherical sodium chloride with a particle size of 600 μm.

[0042] Preparation of powder: pure polyetheretherketone material has a solid structure in the middle; spherical sodium chloride particles and polyetheretherketone powder are mixed at a ratio of 3:7 as the raw material of the outer ring porous body.

[0043] Molding: The powder pressing molding method is adopted, the solid part in the middle is first pressed into a flat plate, and the powder of the porous body is filled; then sintering is carried out at a temperature of 380°C for 1 hour.

[0044] Bend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com