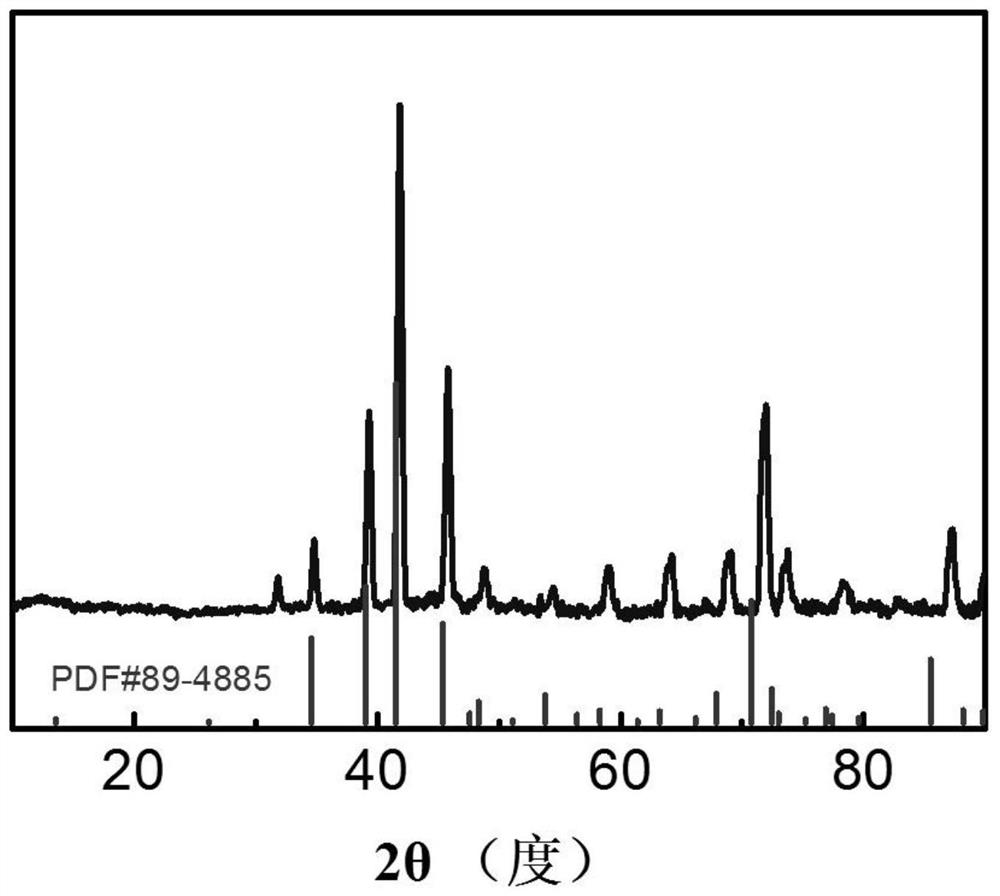

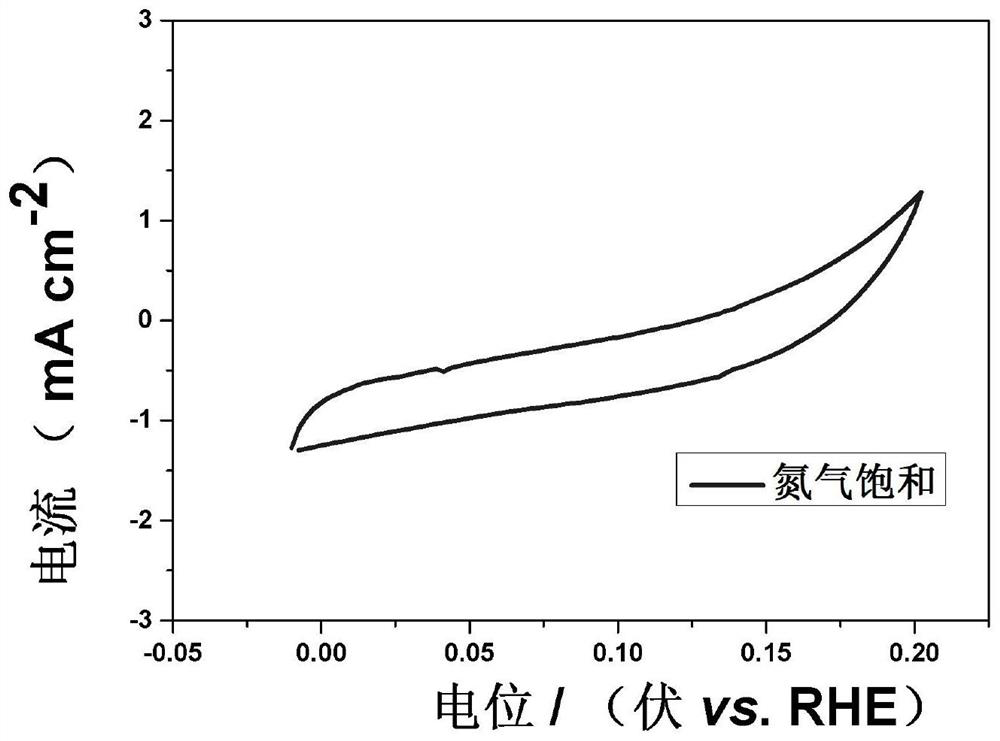

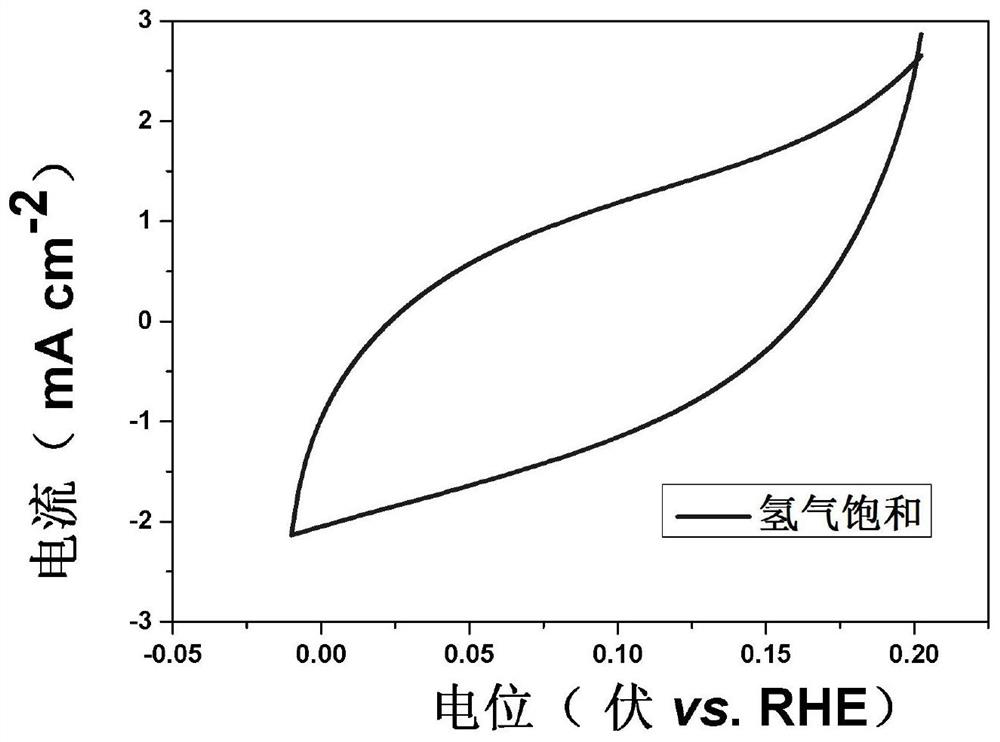

A kind of heteroatom-doped cobalt-molybdenum binary metal carbide nanocomposite material and its preparation method and application

A technology of nanocomposite materials and metal carbides, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the limited price of anode hydrogen oxidation reaction, easy to poison platinum group precious metals, resources Scarcity and other issues, to achieve high-efficiency hydrogen oxidation reaction catalytic activity, easy large-scale production, and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032](1) Ultrasonicate 200 mg of commercial foamed cobalt support material in acetone for 5 min, then wash five times with secondary deionized water, then ultrasonicate in 3mol / L hydrochloric acid solution for 10 min, and then wash with secondary deionized water to medium properties, and then rinsed with absolute ethanol three times, and dried in vacuum at 50°C to obtain a pretreated foamed cobalt support material;

[0033] (2) Dissolve 0.909g of cobalt nitrate in 60mL of secondary deionized water, sonicate for 20min, then add 0.551g of ammonium molybdate, sonicate for 30min, then add 0.4g of sodium hypophosphite, and sonicate for 30min to obtain a uniformly mixed Transition metal precursor solution;

[0034] (3) Add the foamed cobalt support material pretreated in step (1) to the transition metal precursor solution obtained in step (2), and ultrasonically treat it for 30 minutes; Reactor at 180°C for 6 hours to obtain a composite intermediate product;

[0035] (4) The inte...

Embodiment 2

[0038] (1) Ultrasonicate 200 mg of commercial foamed cobalt support material in acetone for 5 min, then wash five times with secondary deionized water, then ultrasonicate in 3mol / L hydrochloric acid solution for 10 min, and then wash with secondary deionized water to medium properties, and then washed three times with absolute ethanol, and dried in vacuum at 50°C to obtain the pretreated foamed cobalt support material;

[0039] (2) Dissolve 1.262g of sodium cobalt nitrite in 60mL of secondary deionized water, sonicate for 20min, then add 0.551g of ammonium molybdate, sonicate for 30min, then add 0.4g of sodium hypophosphite, and sonicate for 30min to obtain a uniform mixed transition metal precursor solution;

[0040] (3) Add the foamed cobalt support material pretreated in step (1) to the transition metal precursor solution obtained in step (2), and ultrasonically treat it for 30 minutes; then transfer it to a 100ml polytetrafluoroethylene liner and put it into In a hydrothe...

Embodiment 3

[0043] (1) Ultrasonicate 200 mg of commercial foamed cobalt support material in acetone for 5 min, then wash five times with secondary deionized water, then ultrasonicate in 3mol / L hydrochloric acid solution for 10 min, and then wash with secondary deionized water to medium properties, and then rinsed with absolute ethanol three times, and dried in vacuum at 50°C to obtain a pretreated foamed cobalt support material;

[0044] (2) Dissolve 0.909g of cobalt nitrate in 60mL of secondary deionized water, sonicate for 20min, then add 0.551g of ammonium molybdate, sonicate for 30min, then add 0.4g of sodium hypophosphite, and sonicate for 30min to obtain a uniform transition Metal precursor solution;

[0045] (3) Add the foamed cobalt support material pretreated in step (1) to the transition metal precursor solution obtained in step (2), and ultrasonically treat it for 30 minutes; then transfer it to a 100ml polytetrafluoroethylene liner and fill it with water Heat the reaction ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com