Colloid molecular structure magnetic mesoporous organic silicon composite microsphere and preparation method thereof

A technology of mesoporous organosilicon and molecular structure, which is applied in the preparation of microspheres, microcapsule preparations, nanotechnology, etc., can solve the problems of "difficult to control covalent bonds and difficult to control the appearance of composite microspheres in the synthesis, and achieve a simple synthesis process. Controllable, simple and controllable preparation process, regular morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

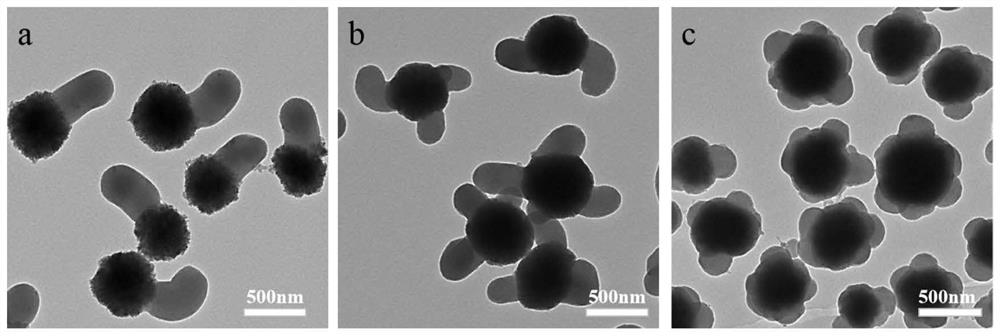

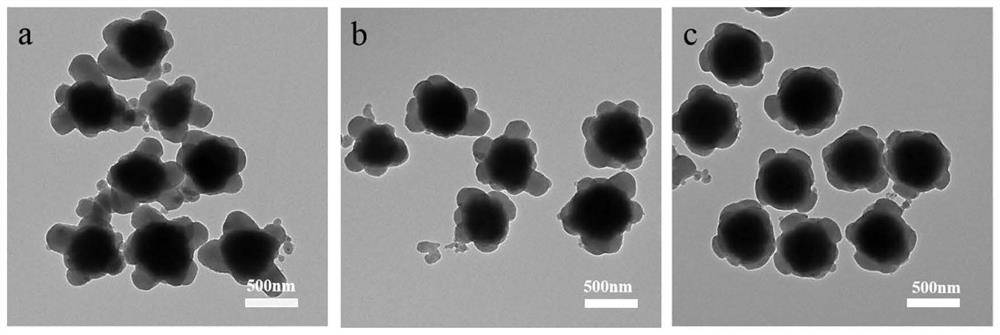

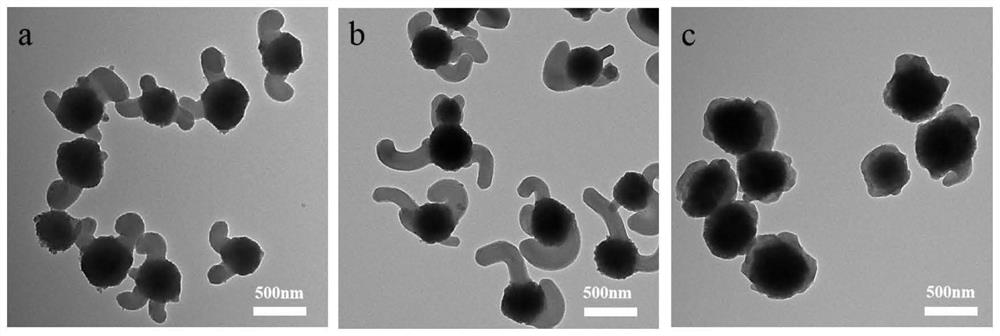

[0040] Such as Figure 7 As shown, a method for preparing magnetic mesoporous silicone composite microspheres with adjustable covalent bonds of "colloidal molecule" structure comprises the following steps:

[0041] (1) Preparation of magnetic Fe by solvothermal method 3 o 4 Nanoparticles (i.e. magnetic ferric oxide seed particles);

[0042] The magnetic Fe 3 o 4 The average particle size of the nanoparticles is: 150nm-350nm.

[0043] (2) Using tetraethyl silicate and dialkylorganosilane as silicon source precursor, cationic surfactant as porogen and nucleating agent, in magnetic Fe 3 o 4 Heterogeneous nucleation and growth of silica spheres hybridized with organic functional groups on the surface of nanoparticles to obtain magnetic silica spheres with a colloidal molecular structure;

[0044] (3) Use ammonium nitrate-ethanol solution to extract and remove the porogen in the organic functional group hybridized silica spheres to obtain magnetic mesoporous silicone spheres...

Embodiment 1

[0046] Embodiment 1 (as comparative example)

[0047] (1) Preparation of magnetic Fe with a particle size of 300 nm by solvothermal method 3 o 4 Nanoparticles;

[0048] (2) With tetraethyl silicate and dialkyl organosilane as silicon source, cationic surfactant as porogen and nucleating agent, in Fe 3 o 4 The heterogeneous nucleation and growth of organic functional group hybrid silica spheres on the surface of nanoparticles, the specific process is:

[0049] The 300nm Fe 3 o 4 The aqueous solution was dispersed in a mixed solution of 20mL deionized water and 50mg cetyltrimethylammonium chloride. After ultrasonic treatment for 30 minutes, it was transferred to a water bath at 40°C. After mechanical stirring for 10 minutes, concentrated ammonia water was added. After 30 minutes, silicon was added dropwise. Acetate tetraethyl ester (dropping rate is 0.024 mL / min), so that Fe 3 o 4 The molar ratio of seed particles / hexadecyltrimethylammonium chloride / ammonia water / silicon...

Embodiment 2

[0052] Compared with Example 1, only change the kind and the consumption that add alkoxysilane, make Fe 3 o 4 The molar ratio of seed particle / surfactant / ammonia / silicon source precursor is 1 / 1.4 / 72 / 6, wherein the volume ratio of tetraethyl silicate and 1,2-bis(triethoxysilyl)ethane is 5 / 1, other steps are the same, get AX 3 Magnetic mesoporous silicone composite microspheres with "colloidal molecule" structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com