Preparation method of graphene-doped aluminum alloy conductor

An aluminum alloy wire and graphene technology, which is applied in the field of aluminum alloy materials, can solve the problems of inability to meet the industrial production requirements of aluminum alloy wires, restricting the development and application of material technology, and unsatisfactory graphene enhancement effect, and achieves improved dispersibility, The effect of grain refinement and crystallization and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

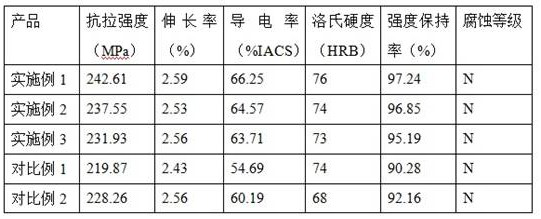

Embodiment 1

[0027] A method for preparing a graphene-doped aluminum alloy wire, the wire material is made of the following raw materials by mass percentage: magnesium 1.3%, iron 0.4%, vanadium 0.04%, silicon 0.5%, titanium 0.02%, tellurium 0.01%, Indium 0.03%, rare earth element 0.10%, graphene 1.2%, the balance is aluminum and inevitable impurities; the rare earth element is composed of the following mass percentages of raw materials: cerium 40%, erbium 25%, yttrium 28% and samarium 7% %.

[0028] The preparation method of the aluminum alloy wire comprises the following steps:

[0029] (1) Smelting aluminum ingots (purity ≥99%) into molten aluminum, adding graphene modified suspension and mixing evenly, then introducing molten aluminum into a holding furnace, heating up to 730°C, and holding for 2 hours to obtain graphene doping Aluminum liquid; the preparation method of described graphene modified suspension is: disperse graphene in ethanol solution, then add mass ratio of 1:2:1 cocami...

Embodiment 2

[0035] A preparation method of a graphene-doped aluminum alloy wire, the wire material is made of the following raw materials by mass percentage: magnesium 1.8%, iron 0.8%, vanadium 0.05%, silicon 0.3%, titanium 0.05%, tellurium 0.02%, Indium 0.02%, rare earth element 0.15%, graphene 1.2%, the balance is aluminum and inevitable impurities; the rare earth element is composed of the following raw materials by mass percentage: cerium 45%, erbium 20%, yttrium 25% and samarium 10% %.

[0036] The preparation method of the aluminum alloy wire comprises the following steps:

[0037] (1) Smelting aluminum ingots (purity ≥99%) into molten aluminum, then adding graphene modified suspension to mix evenly, then introducing molten aluminum into a holding furnace, heating up to 700°C, and holding for 2.5 hours to obtain graphene doped Miscellaneous aluminum liquid; the preparation method of described graphene modified suspension is as follows: graphene is dispersed in ethanol solution, the...

Embodiment 3

[0043] A method for preparing a graphene-doped aluminum alloy wire, wherein the wire material is made of the following raw materials in mass percentage: 1.5% magnesium, 0.5% iron, 0.03% vanadium, 0.4% silicon, 0.03% titanium, 0.03% tellurium, 0.03% indium, 0.20% rare earth element, 1.0% graphene, and the balance is aluminum and unavoidable impurities; the rare earth element is composed of the following raw materials in mass percentage: 35% cerium, 30% erbium, 30% yttrium and samarium 5 %.

[0044] The preparation method of the aluminum alloy wire comprises the following steps:

[0045] (1) Melt aluminum ingots (purity ≥ 99%) into molten aluminum, then add graphene-modified suspension and mix evenly, then introduce molten aluminum into a holding furnace, heat up to 750°C, and keep warm for 1.5h to obtain graphene-doped Miscellaneous aluminum liquid; the preparation method of described graphene modified suspension is: graphene is dispersed in the ethanol solution, then add the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| Strength retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com